Digital control pipe bending machine

A pipe bending machine and pipe bending part technology, applied in the direction of forming tools, feeding devices, positioning devices, etc., can solve the problems of manual positioning quality cannot be guaranteed, reduce the speed of mold change, increase labor force, etc., to achieve practicality and Strong reliability, improved stability, and improved labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

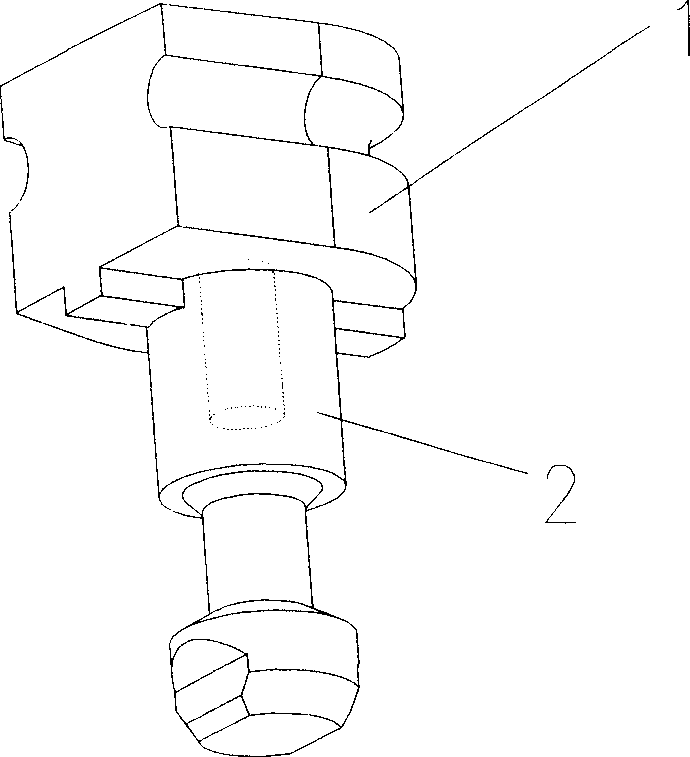

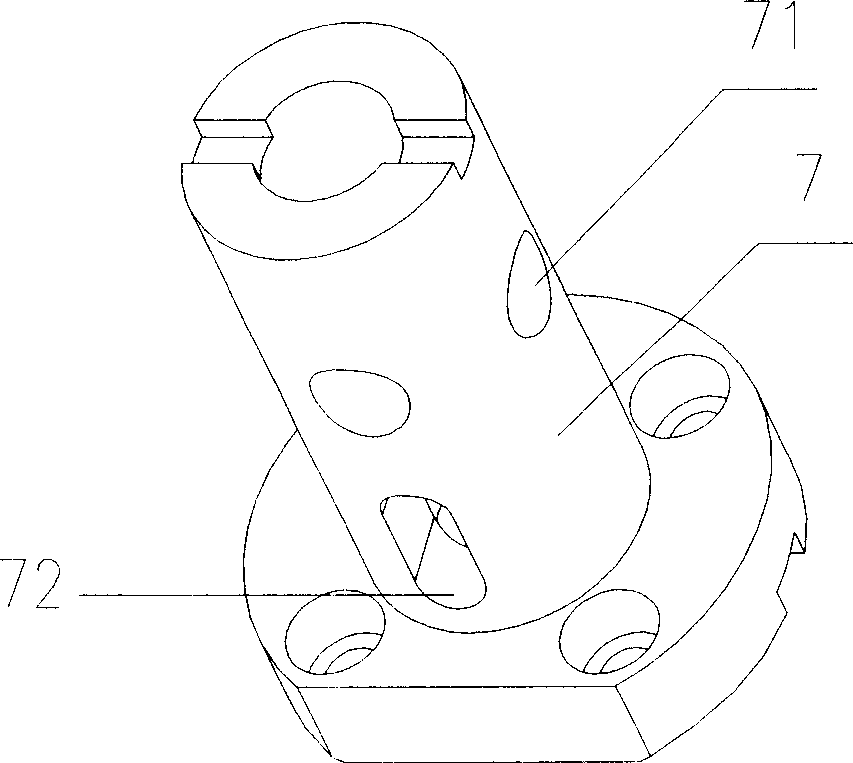

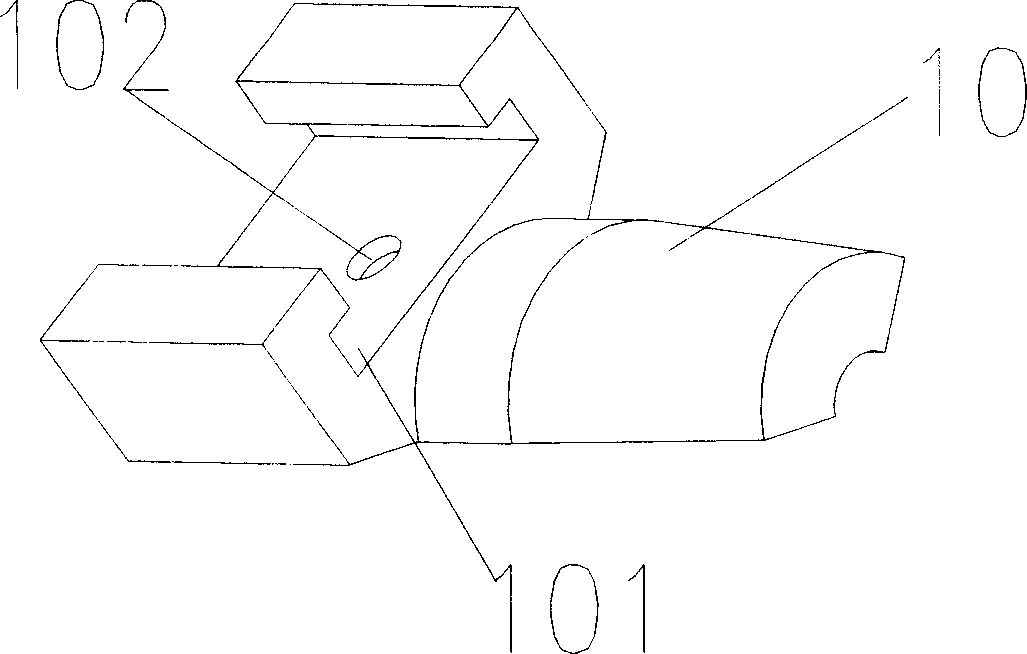

[0016] A numerical control pipe bending machine, which includes a control part, a mechanical part and auxiliary parts, the auxiliary parts are mainly various cylinders, valve bodies, switches, servo motors and servo controllers, etc., and the control part can control the actions of the above auxiliary parts , the mechanical part mainly includes a frame, a feeding part, a pipe bend part and a feeding part, and the control part and the mechanical part are introduced respectively in conjunction with the accompanying drawings:

[0017] 1. Control part

[0018] The operation control panel adopts PIPE BENDER CNC series 2003M+ controller, and the display adopts 5" blue-bottom LCD screen; integrated anti-fouling keyboard; the controller programming software adopts the Chinese language operation version. There are G-M code programming, program template editing, and data filling; It can automatically generate active drawing and active pipe bending programs. It is equipped with Chinese v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com