Magnetic-field isostatic press provided with film dry bag

An isostatic press and isostatic pressing technology, applied in the field of magnetic powder forming equipment, can solve problems such as low orientation magnetic field strength, low efficiency, and inability to press non-circular workpieces, so as to improve quality, improve processing efficiency, and ensure reliability The effect of suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

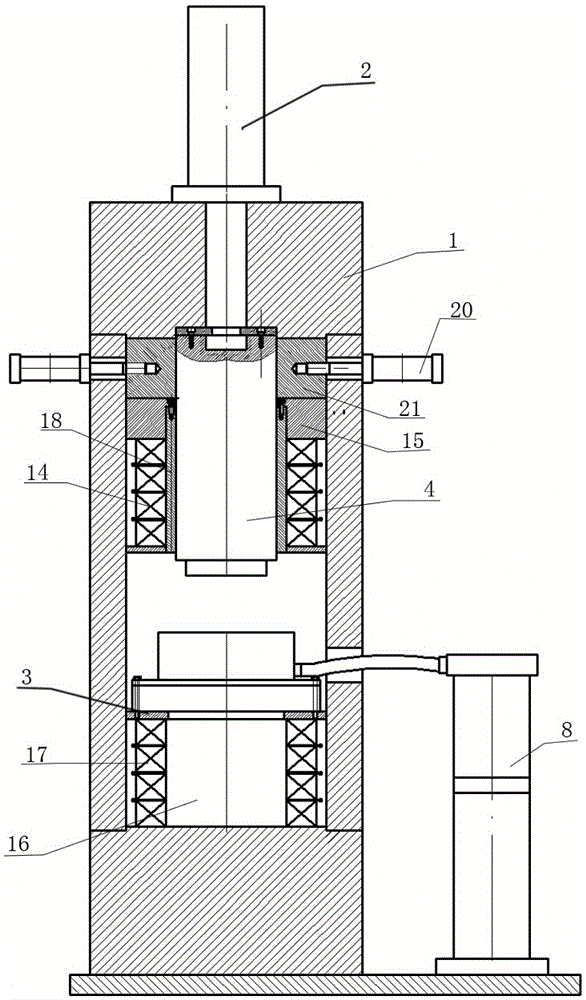

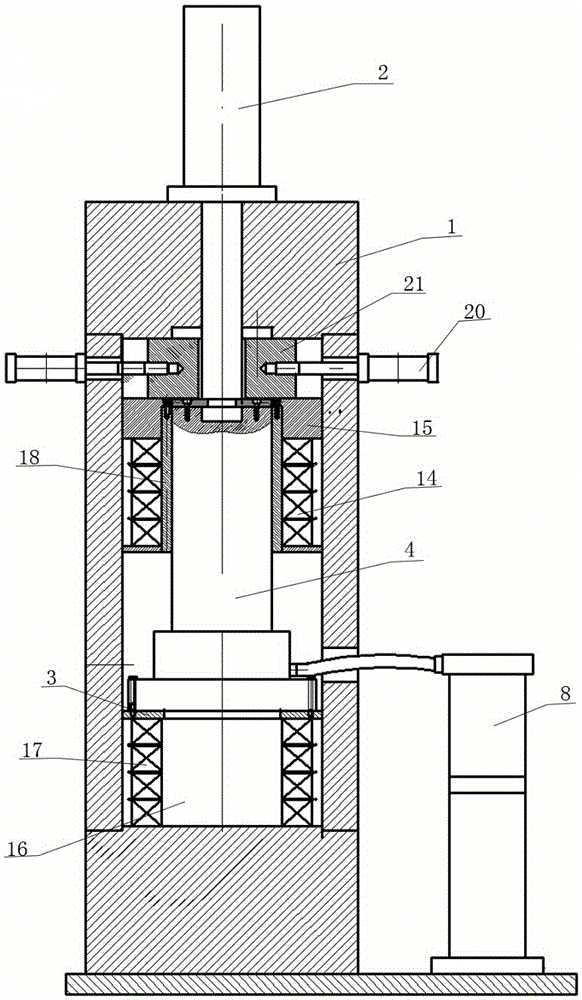

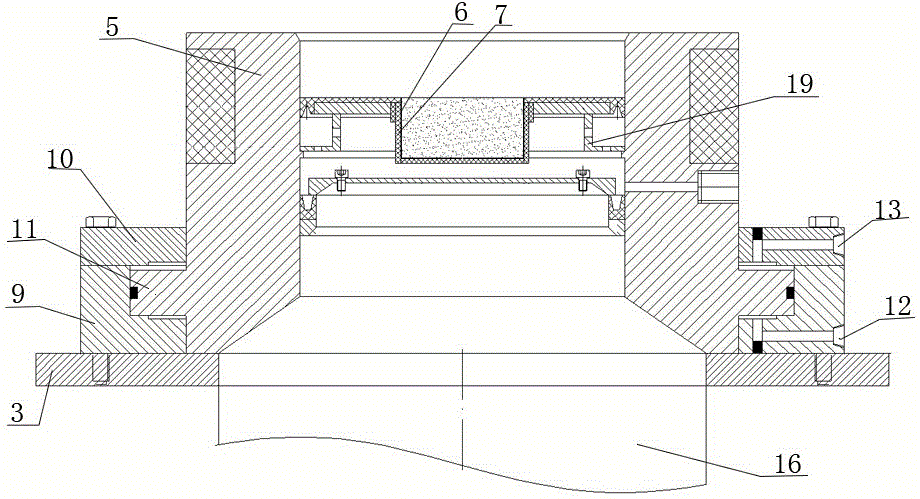

[0024] Film dry bag magnetic field isostatic press, including frame 1, frame 1 is a frame structure, upper oil cylinder 2 is arranged on the top of frame 1, workbench 3 is arranged in the middle of the frame, and isostatic pressure is placed on workbench 3 mold, the piston rod of the upper oil cylinder 2 passes through the upper beam of the frame frame and is fixed with the sealing pressure column 4 of the isostatic pressing mold at its end, and an orientation electromagnetic field device is respectively arranged above and below the isostatic pressing mold; The isostatic pressing mold includes a high-pressure cavity 5 and a dry bag 6 in the high-pressure cavity. The dry bag 6 is composed of an upper support connection part sealed with the inner wall of the high-pressure cavity and a lower working part; Porous air-permeable rigid former 7, the working part of dry bag 6 is positioned at the mold cavity of former 7, and the working part of dry bag 6 is made of film, and the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com