Slant-hole gas cutting method of large-scale thick-wall forgeable piece tube

A cylinder and gas cutting technology, which is applied in the direction of gas flame welding equipment, welding equipment, metal processing equipment, etc., to achieve the effect of simple and practical implementation, labor intensity reduction and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

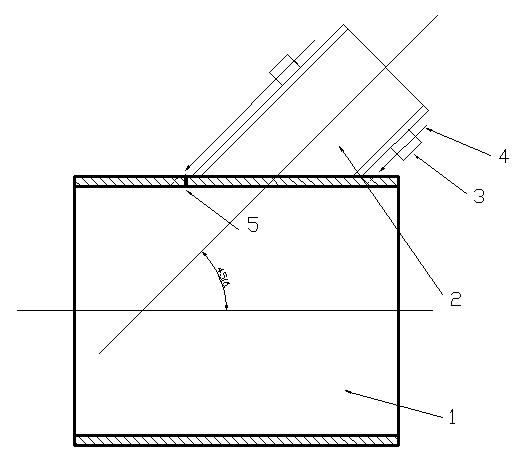

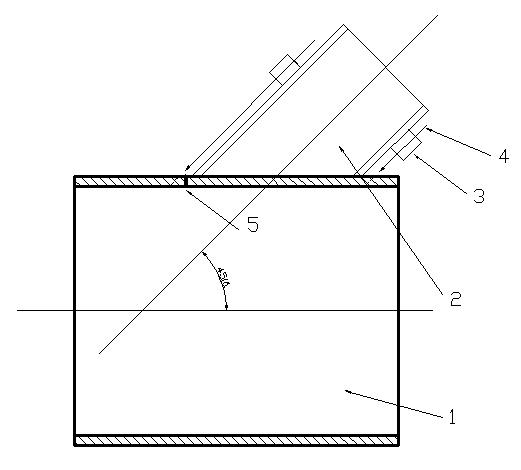

[0028] Such as figure 1 As shown, the diameter of the embodiment is 3710mm, the thickness of the cylinder is 150mm, the maximum cutting thickness is 30-298mm, the cutting angle is 45°, and the opening diameter is 20-2070mm.

[0029] The cutting device is composed of a master model 2, a semi-automatic cutting machine 3 and a cutting nozzle 4. In order to achieve the purpose of cutting and opening, first drill and cut the guide hole 5 on the cylinder, then install the master 2 on the cylinder 1 of the large forging, then install the semi-automatic cutting machine 3 on the master 2, and finally in the semi-automatic cutting The cutting nozzle 4 is installed on the machine 3, and the semi-automatic cutting machine 3 walks along the master form 2, and the cutting nozzle 4 cuts the large forging in sections by means of oxy-acetylene cutting to complete the purpose of opening.

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com