Method for processing alnico magnetic sheet

A processing method and aluminum-nickel-cobalt technology, applied in the field of mechanical processing, can solve problems such as failure to meet product technical requirements, and achieve the effect of reducing production costs and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Instruments and equipment:

[0035] 1. Tesla meter: LZ-610H, Hunan Lianzhong Technology Co., Ltd.

[0036] 2. High-precision surface grinder: KGS-306AH, Ningbo Dewei Machinery Co., Ltd.

[0037] 3. Digital measuring projector: CPJ-3015, Wanhao Precision Instrument Co., Ltd.

[0038] 4. Wire cutter (with processing track display): DK7720, Shanghai Renyi Machine Tool Co., Ltd.

[0039] DK77-30, Zhejiang Dewei Machine Tool Factory.

[0040] 5. Multimeter: TM-5210, Japan Dele.

[0041] Specific processing method:

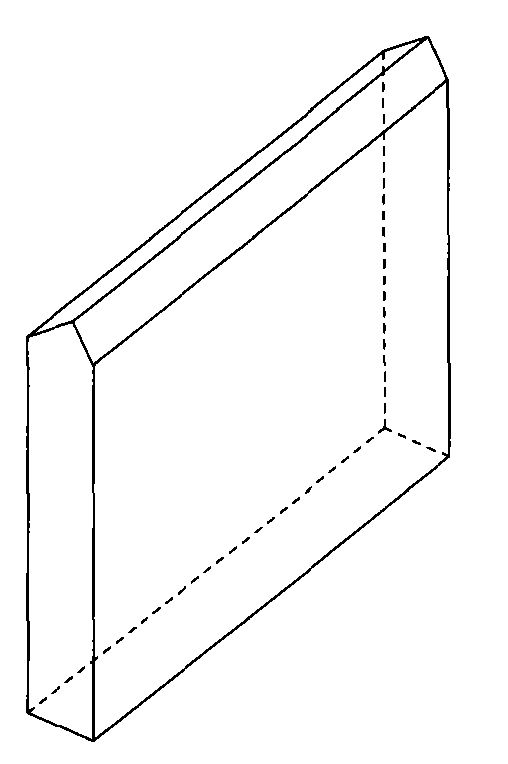

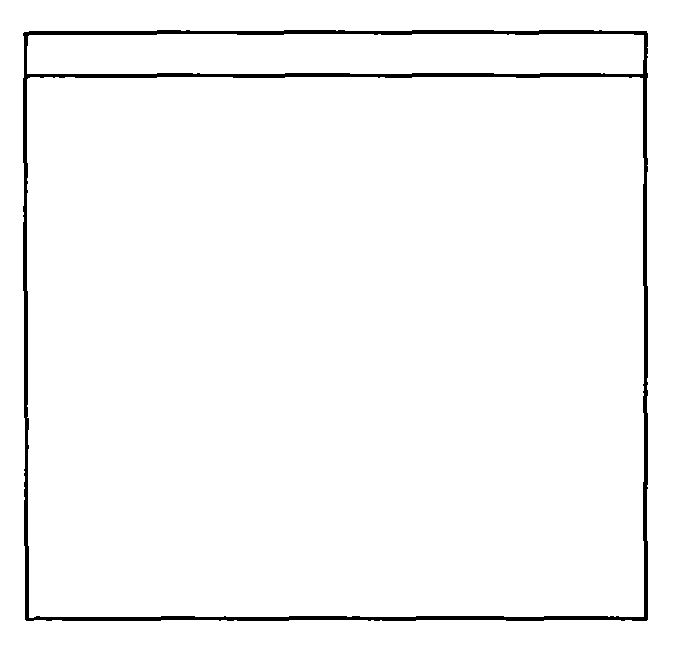

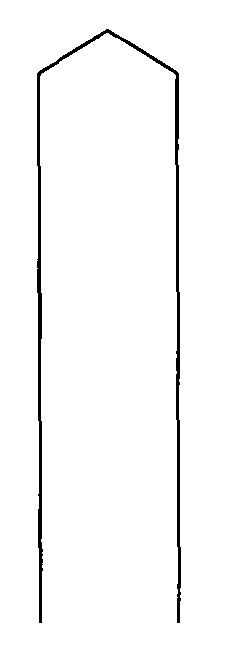

[0042] To Figure 1-3 The shown AlNiCo magnetic sheet is taken as an example, and the size requirements are as follows: length * width * thickness = 0.135 * 0.128 * 0.0320 inches, and the top angle is 120°. The appearance of this kind of product is very small, the tolerance is 0.00012 to 0.00019 inches, and the angle tolerance is within 10 minutes.

[0043] The processing steps are as Figure 5 Shown:

[0044] 1. Measure the magnetization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com