Method and equipment for manufacturing screw rod

A production method and screw technology, applied in the field of machinery, can solve problems such as low processing efficiency, low precision consistency, and difficult polishing, and achieve the effects of reducing production costs, improving work efficiency, and overcoming low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

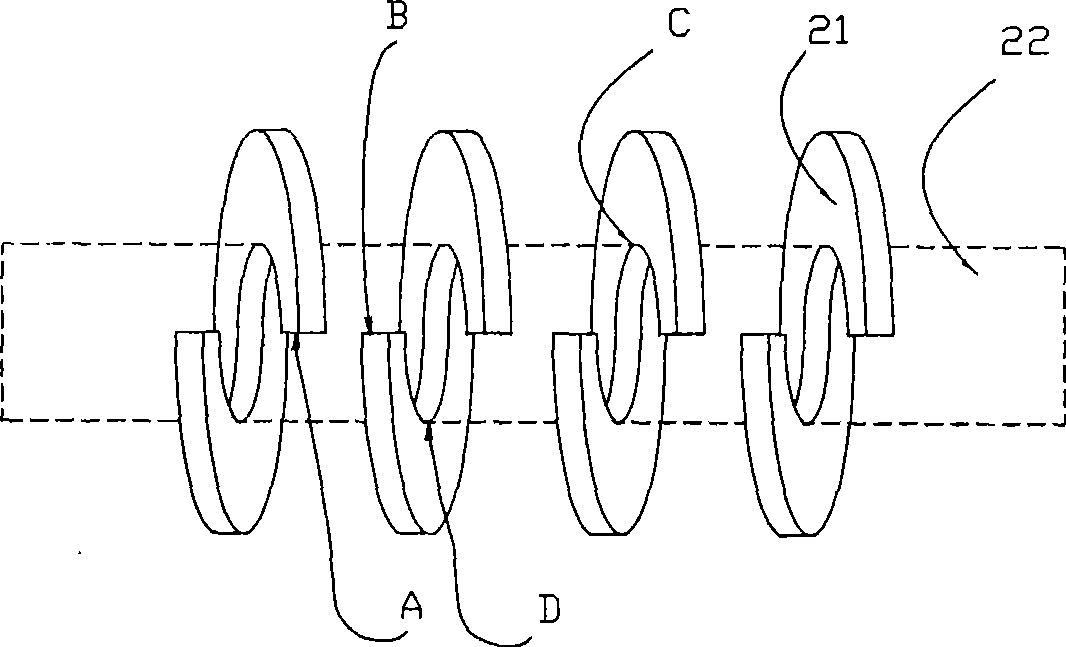

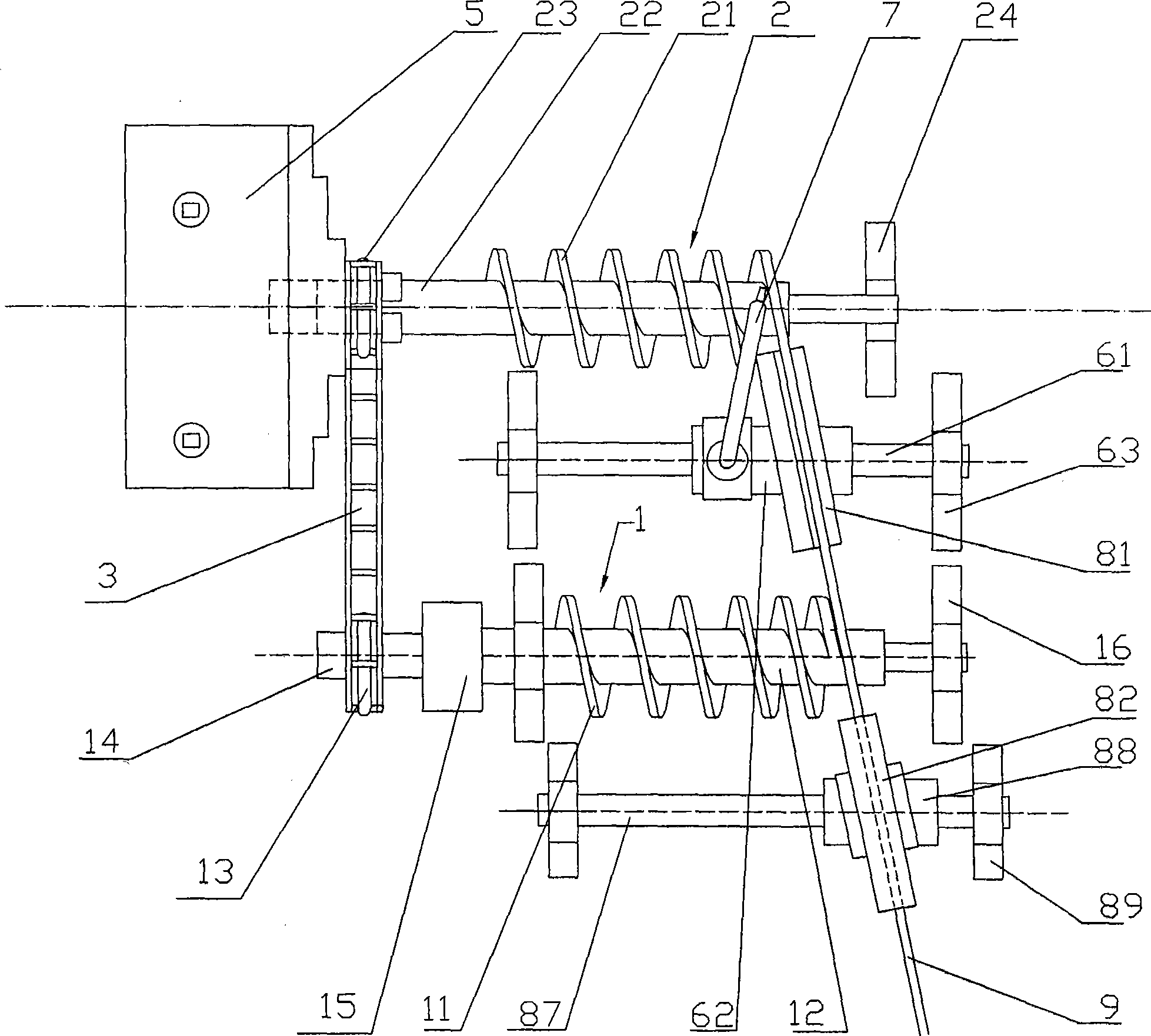

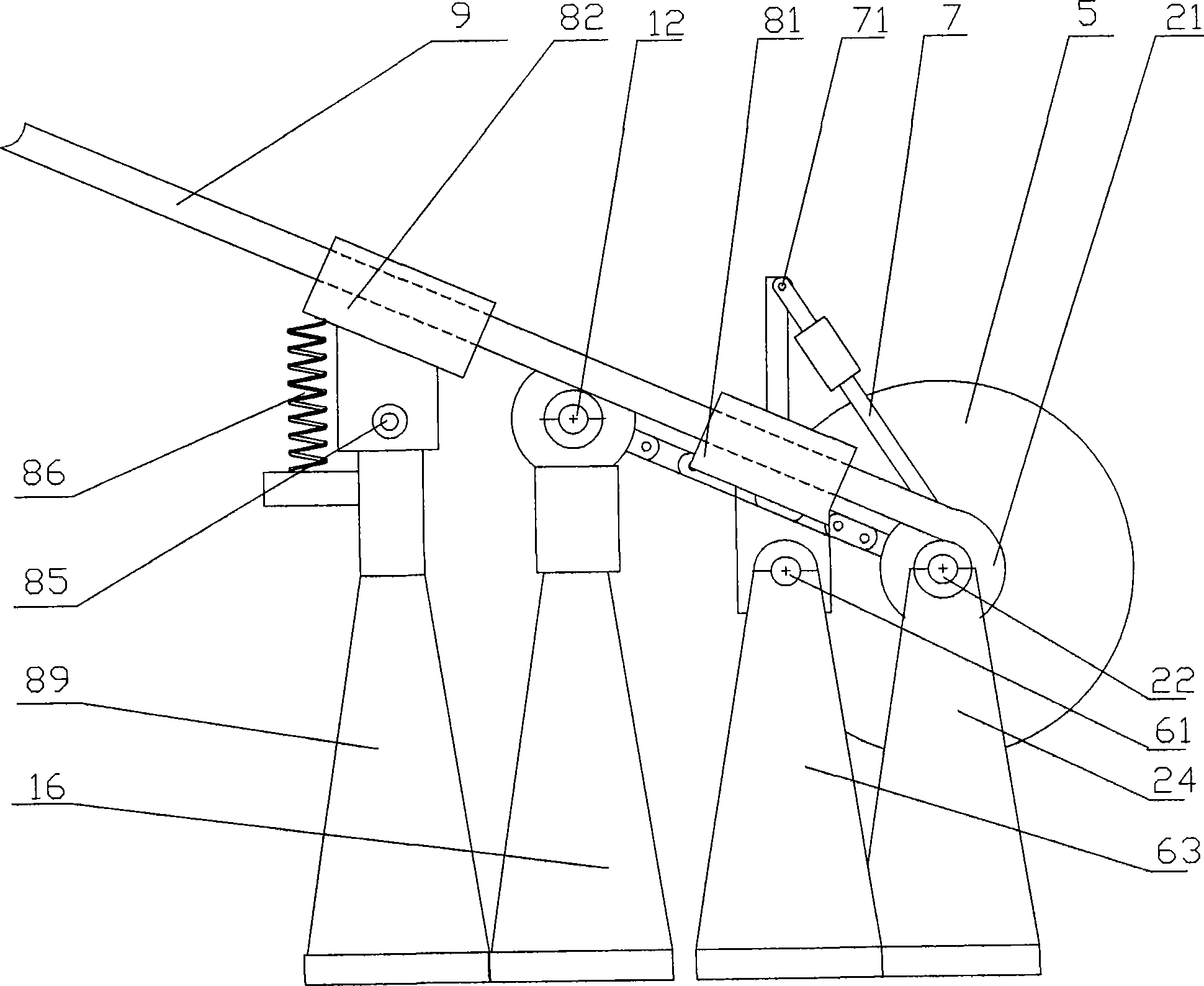

[0026] A method for making a screw. First, a standard screw made by a conventional method is selected as a template, the standard screw is fixed and rotatable, and the shaft of the processed screw is fixed and rotatable parallel to the standard screw; Between the screw and the rotating shaft of the processed screw, a pair of slide rail sliders is arranged in parallel. The guide clamps and welding guns are installed on the sliders, so that the guide clamps and welding guns can move simultaneously with the sliders. The setting direction of the guide clamps is the same as The angles of standard screw threads are the same; the processing process is:

[0027] a. A flat steel bar with a thickness equivalent to the thickness of the standard screw thread and a width equivalent to the standard screw thread depth is pressed against the side that produces pressure when the thread at the beginning of the standard screw rotates, and its end vertically passes through the guide clamping The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com