Automatic grafting machine for vegetable

A vegetable and rack technology, which is applied in the field of machines for vegetable grafting, can solve the problems of high technical requirements, high price and labor, and achieve the effects of simple working principle, short machine transmission route and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

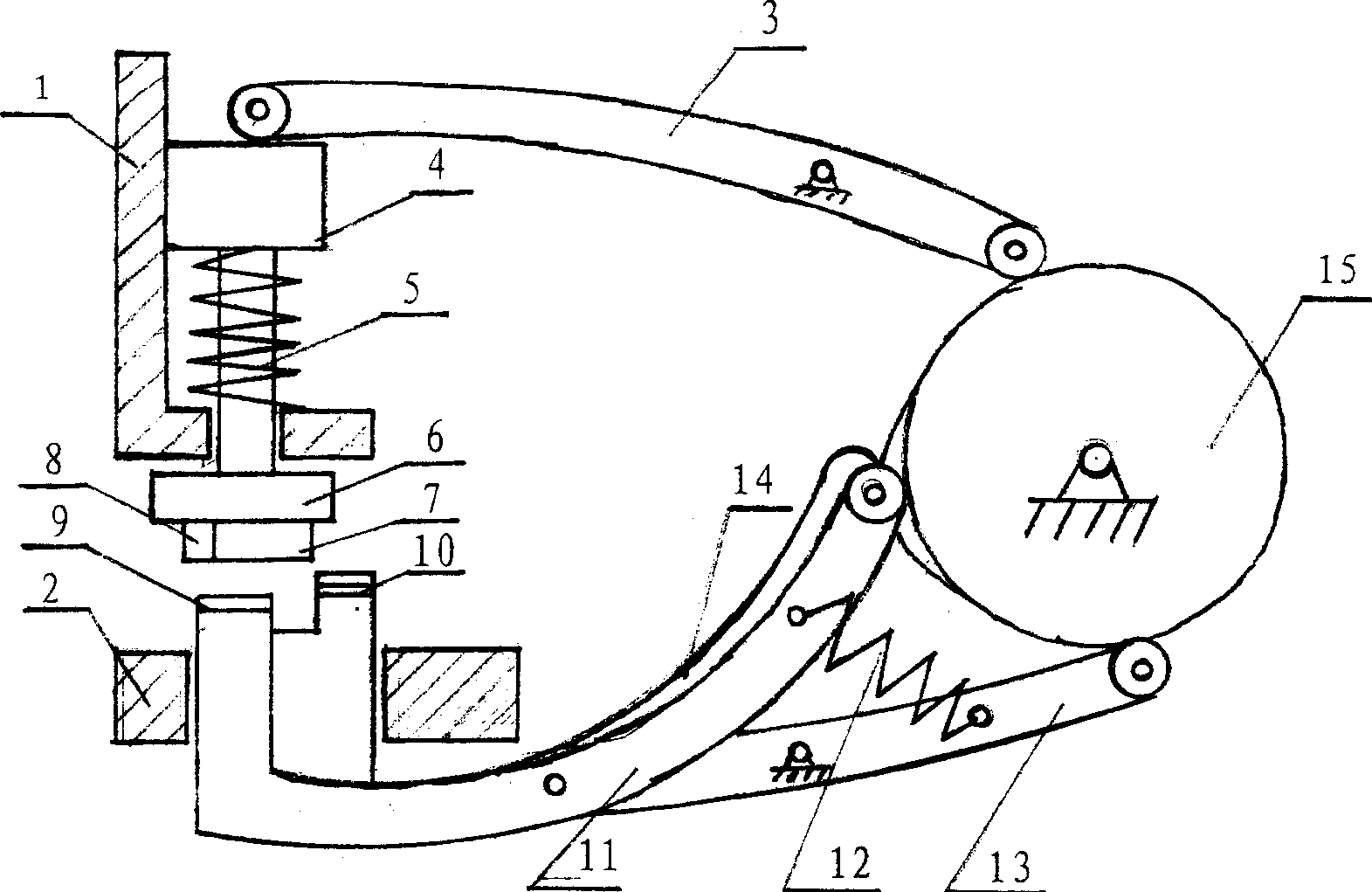

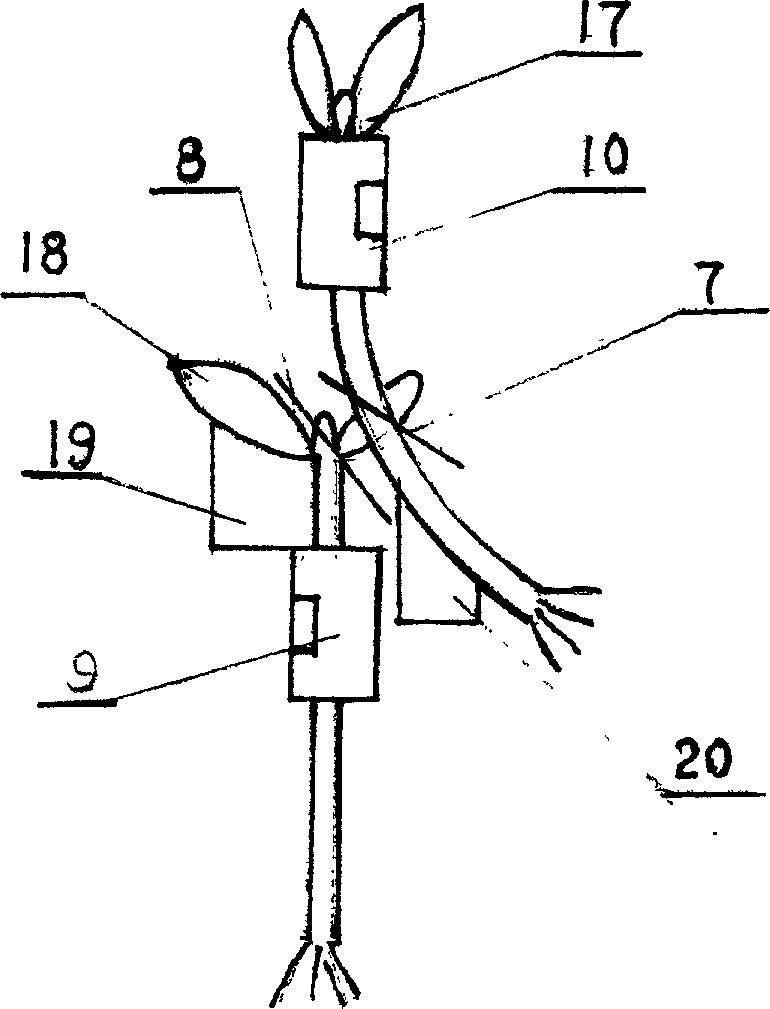

[0012] exist figure 1 When the work starts, the cutting knives (7) and (8) on the knife bar (6) of the knife rest (1) are above the workbench (2), and the thrust of the cam (15) is the same as that of the rootstock clamp swing bar (11) Contact with the scion clip swing bar (14), the rootstock clip swing bar and the scion clip swing bar are relatively opened with the support swing bar (13), the spring (12) is in the compressed position, the stock clip (9) and the scion clip (10) All open.

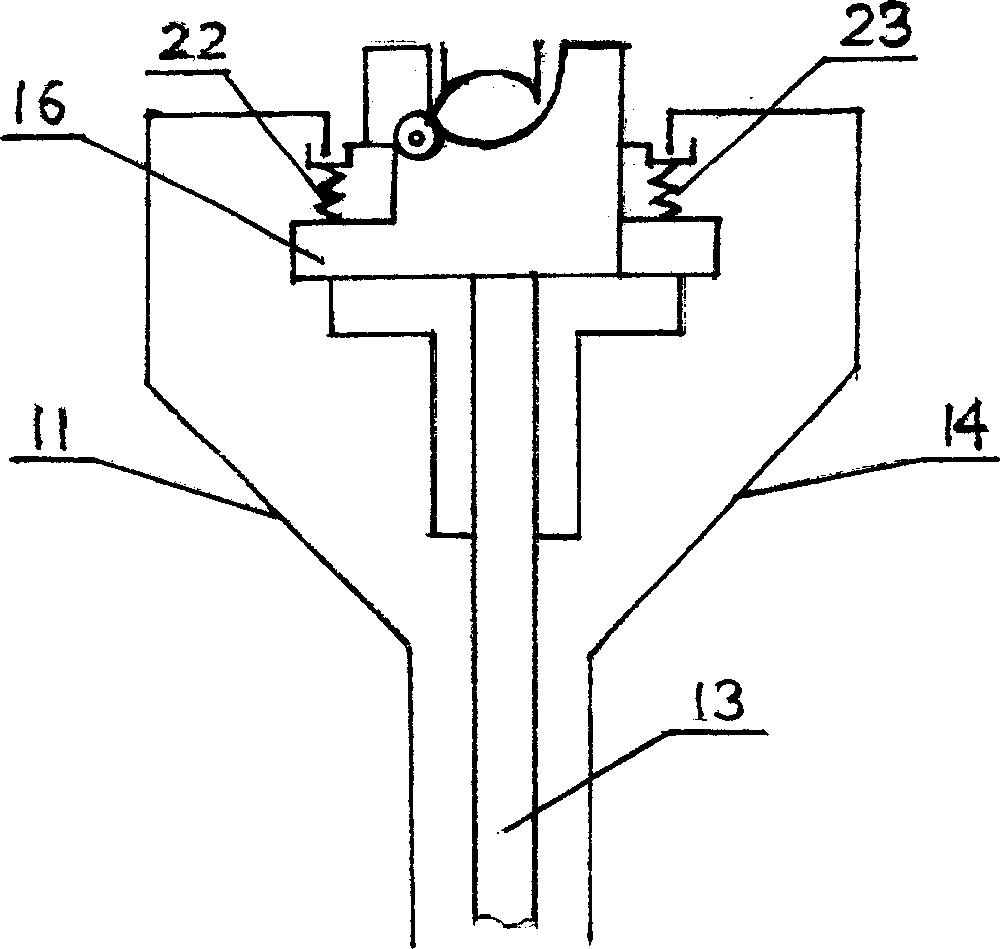

[0013] exist figure 2 Among them, there are springs (22), (23) on the fixed support (16) with the support swing bar to support the rootstock clip and the fringe clip, which can clamp the rootstock seedling (18) and the scion seedling (17); When the rootstock folder swing bar that links to each other with the support fork and the fringe clip fork produce relative rotation with the support fork, the spring can be depressed to make the rootstock folder and the fringe folder open.

[0014] e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com