Automatic winding and forming device of tank and forming method

A tank, automatic technology, applied in auxiliary devices, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low production efficiency, time-consuming and laborious docking quality, delayed construction period, etc., to improve docking quality and efficiency, and avoid bumps Scratch, improve the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

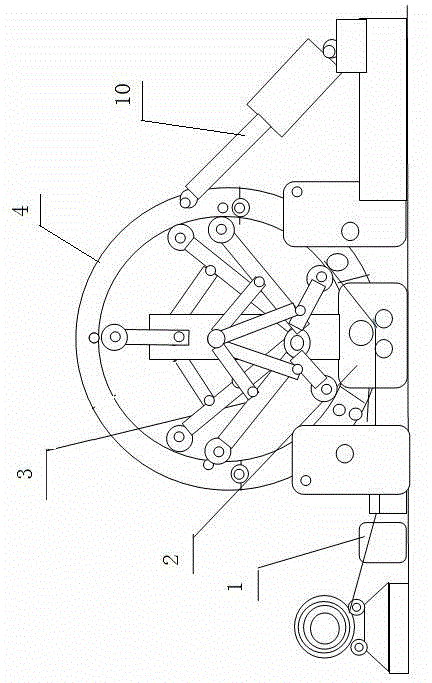

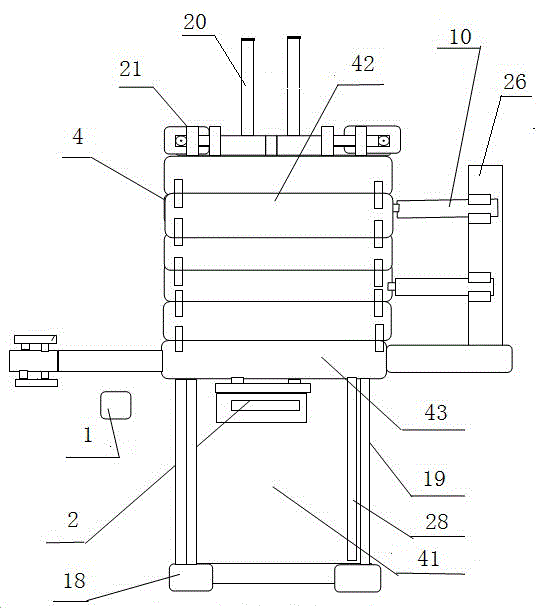

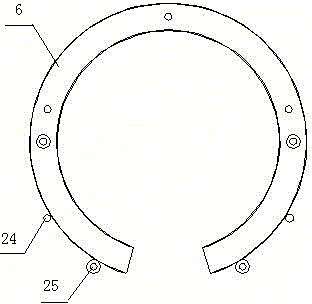

[0025] from figure 1 side view of the invention shown and figure 2 It can be seen from the top view schematic diagram that the tank body automatic rolling and forming device of the present invention includes a blanking device 1, a plate rolling device 2, an auxiliary rolling device 3, a barrel section clamp 4, a barrel section butt spot welding device and a hydraulic system, The plate rolling device 2 is arranged behind the unloading device 1 , and an auxiliary rolling device 3 and a cylinder section clamp 4 are arranged above the plate rolling device 2 . Before the flat or coiled plate enters the coiling device 2, the length of the plate is measured according to the unfolded size, and the cutting device 1 is used for gas cutting. The plate rolling device 2 includes an upper roller and a lower roller. The upper and lower rollers are installed on the support seats at both ends. The support seat at one end of the upper roller can swing. According to the thickness of the sheet,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com