Special-shaped edge trimmer

An edge trimming machine, special-shaped technology, applied in metal sawing equipment, duplication process control system, sawing machine device, etc., can solve problems such as machine not working properly, damage to cutting tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

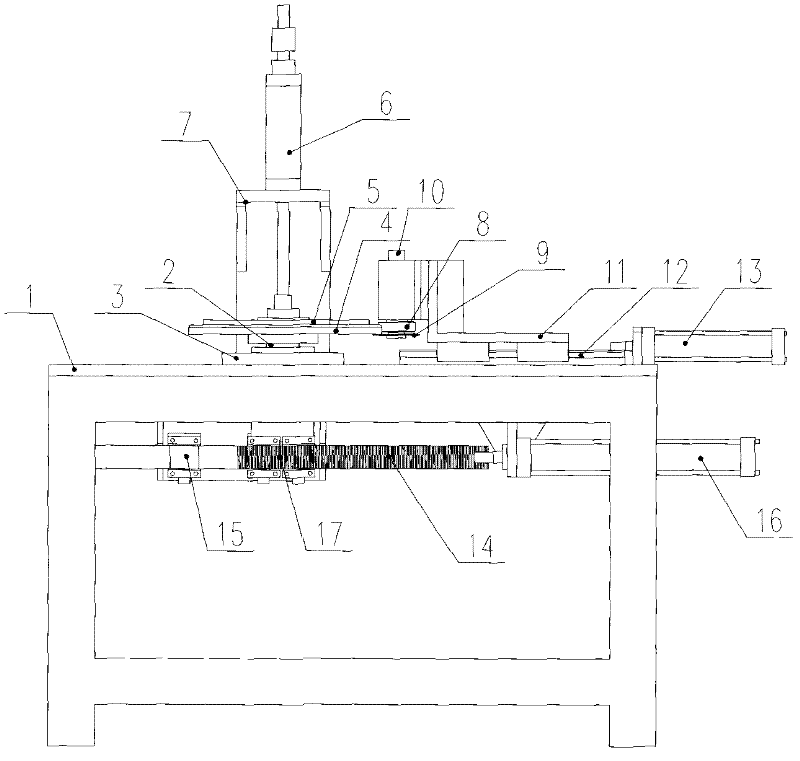

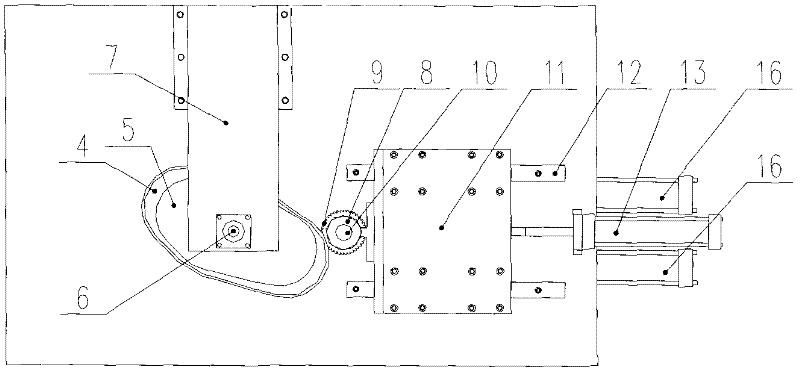

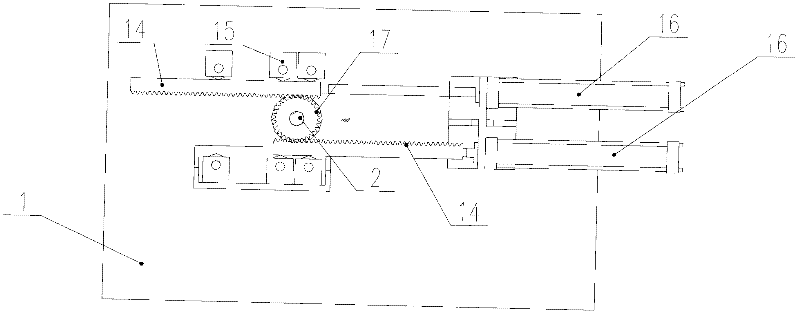

[0018] Such as figure 1 As shown: the central shaft 2 is set on the central shaft seat 3, the central shaft seat 3 is set on the frame 1, the master mold 4 is set on the flange at one end of the central shaft 2, and the upper mold 5 is set on the piston of the die cylinder 6 Above, the cylinder body of the die cylinder 6 is set on the die cylinder seat 7, the die cylinder seat 7 is arranged on the frame 1, the cam wheel 8 and the cutting saw blade 9 are arranged on the cutter shaft 10, and the cutter shaft 10 Be arranged on the cutter seat 11, the cutter seat 11 is arranged on the guide rail 12, the guide rail 12 is arranged on the frame 1, the cylinder body of the cutter seat working cylinder 13 is arranged on the frame 1, the cutter seat working cylinder 13 The piston part is connected with the cutter seat 11, and the cutter seat 11 is pushed by the piston of the cutter seat working cylinder 13, so that the cam wheel 8 is close to the cam 4, and the central shaft gear 17 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com