Spring concentricity and verticality measuring meter and its measurement method

A verticality measuring instrument and concentricity technology, applied in measuring devices, instruments, and optical devices, etc., can solve the problems of low measurement speed, low measurement efficiency, and difficult to guarantee accuracy, and achieve control, high measurement accuracy and stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

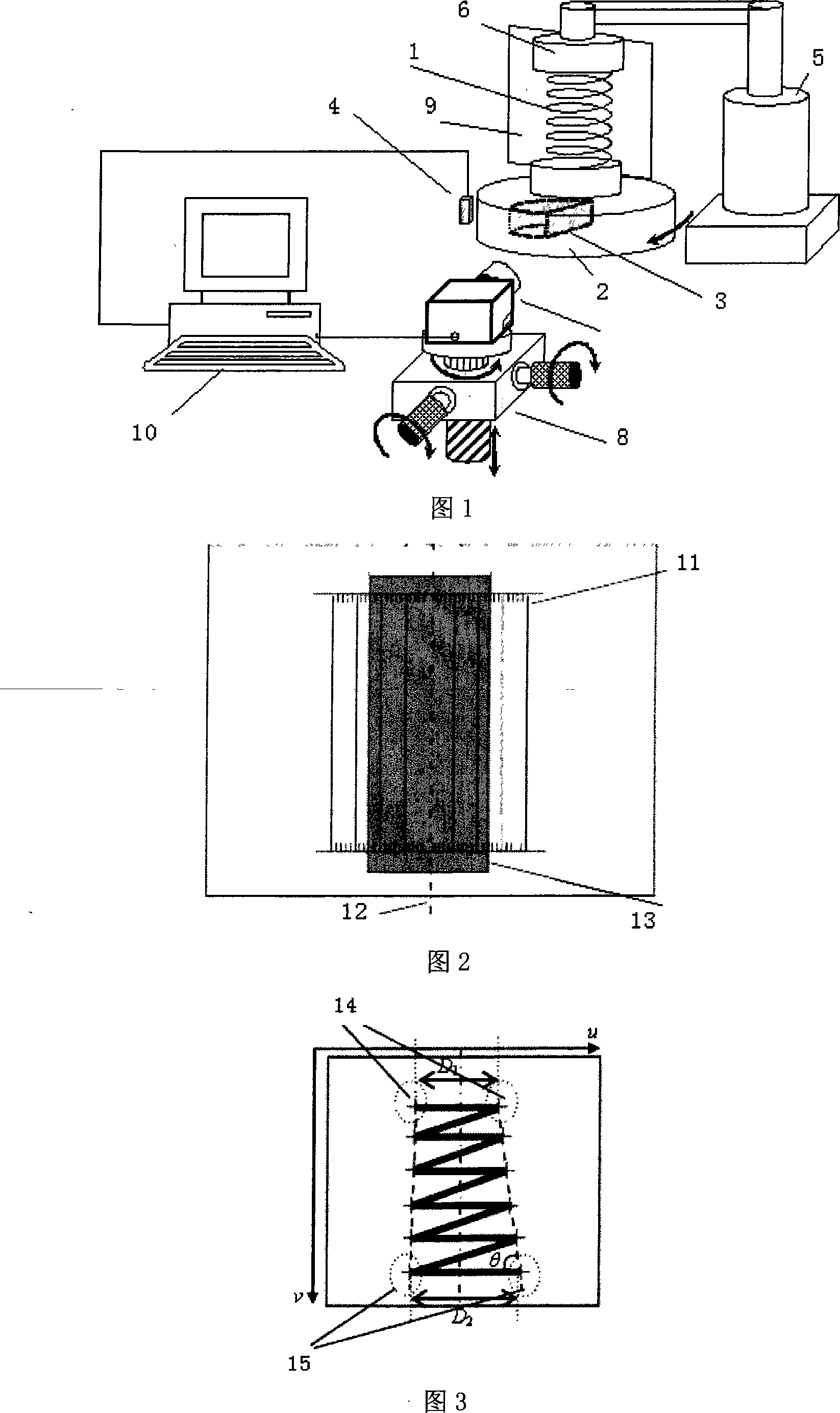

[0042] Fig. 1 is a schematic structural view of a spring 1 concentricity verticality measuring instrument of the present invention. The image of the spring 1 is collected by the CCD camera 7, and the edge information of the spring 1 is extracted by image processing, and the concentricity and perpendicularity are calculated according to the edge information. The backlight plate 9 is placed opposite to the camera 7, and the spring 1 is between the two. The backlight plate 9 projects uniform light to enhance the boundary information of the spring 1, which is easy to process the image of the spring 1; the data obtained by measuring only a single position of the spring 1 The actual information cannot be truly reflected. Therefore, this device uses a CCD camera 7 to conduct a 360° comprehensive measurement of the spring 1 rotated by the base 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com