Full-load passenger car frame overall positioning and clamping tool

A technology of full load-bearing and positioning devices, applied in auxiliary devices, vehicle parts, manufacturing tools, etc., can solve problems such as easy deformation of hoisting, complicated process, and difficult reference positioning, so as to improve product quality, unify the overall reference, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail

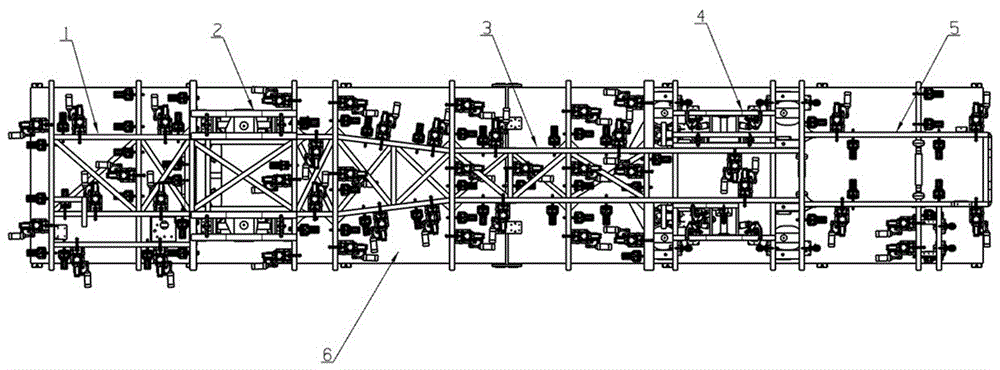

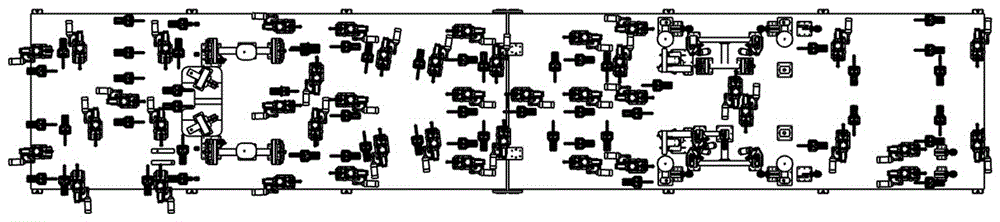

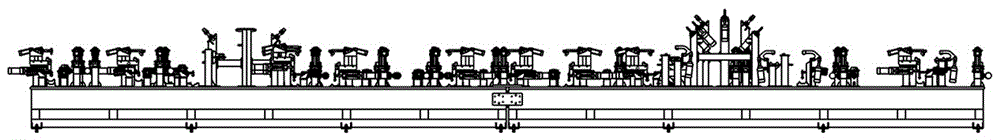

[0027] What the present invention discloses is an overall positioning and clamping tool for a full-load passenger car frame, such as Figure 1 to Figure 11 As shown, it is a preferred embodiment of this case. The full-load frame tooling includes tooling assembly 1 in the driving area, tooling assembly 2 in the front axle area, tooling assembly area 3 in the middle section, and tooling assembly in the rear axle area. 4. Tooling assembly 5 in the driving area, and tooling assembly area 6 in the bottom plate. The top view of the tooling assembly is as follows Figure 4 As shown, the fully loaded frame is as Figure 4 As shown, it includes 7 frame subassemblies in the driving area, 8 frame subassemblies in the front axle area, 9 frame subassemblies in the middle section area, 10 frame subassemblies in the rear axle area, and 11 frame subassembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com