Arc-shaped formwork and moulding bed rapid machining and assembling equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

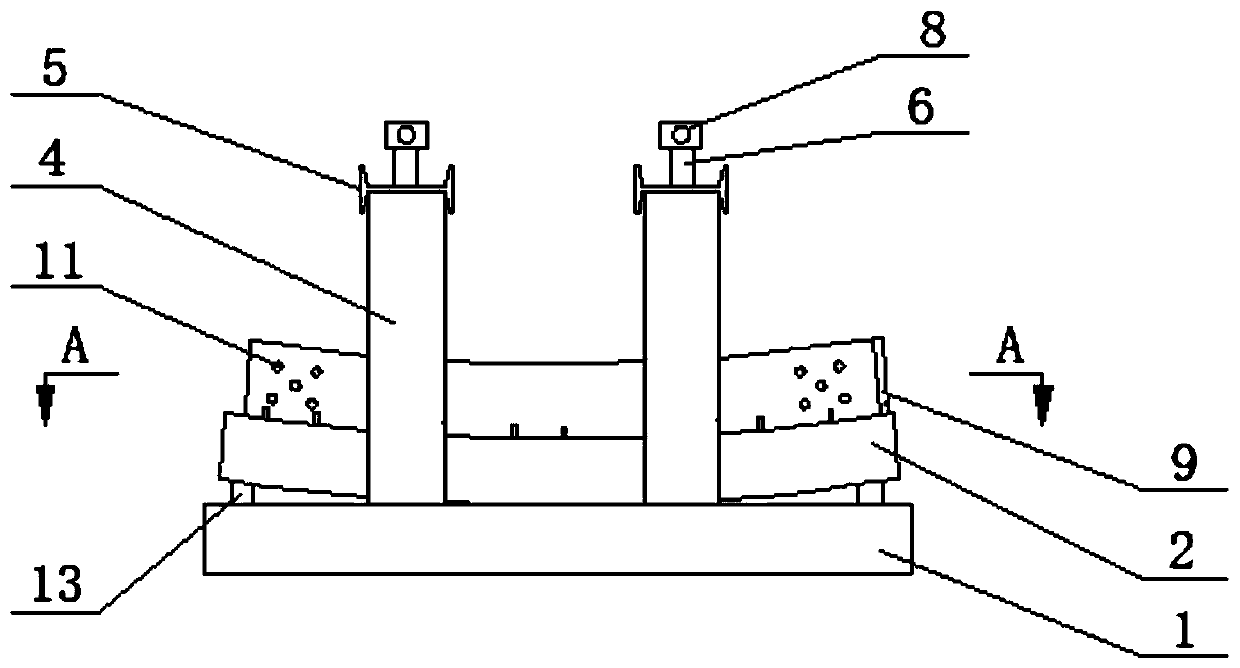

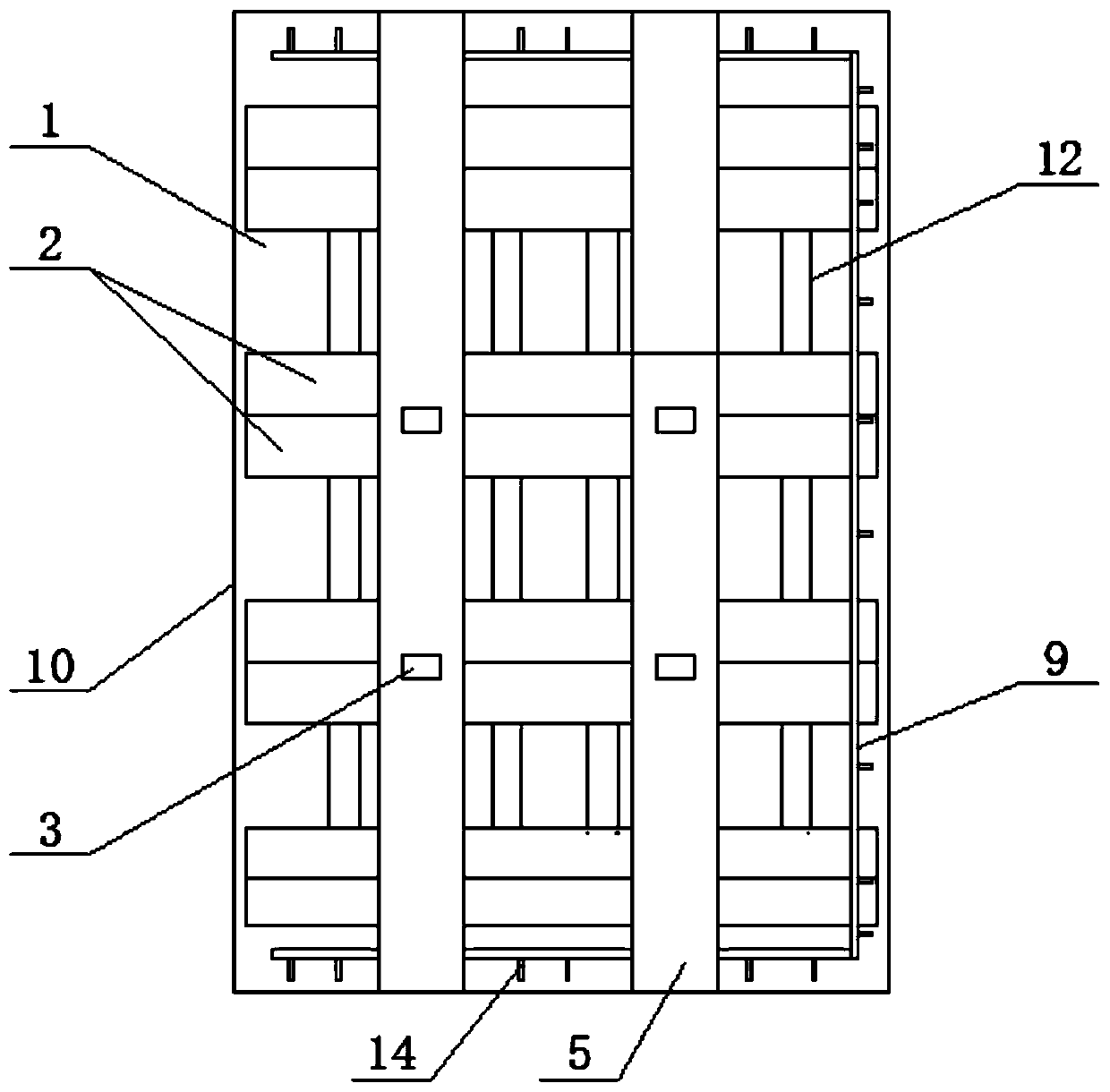

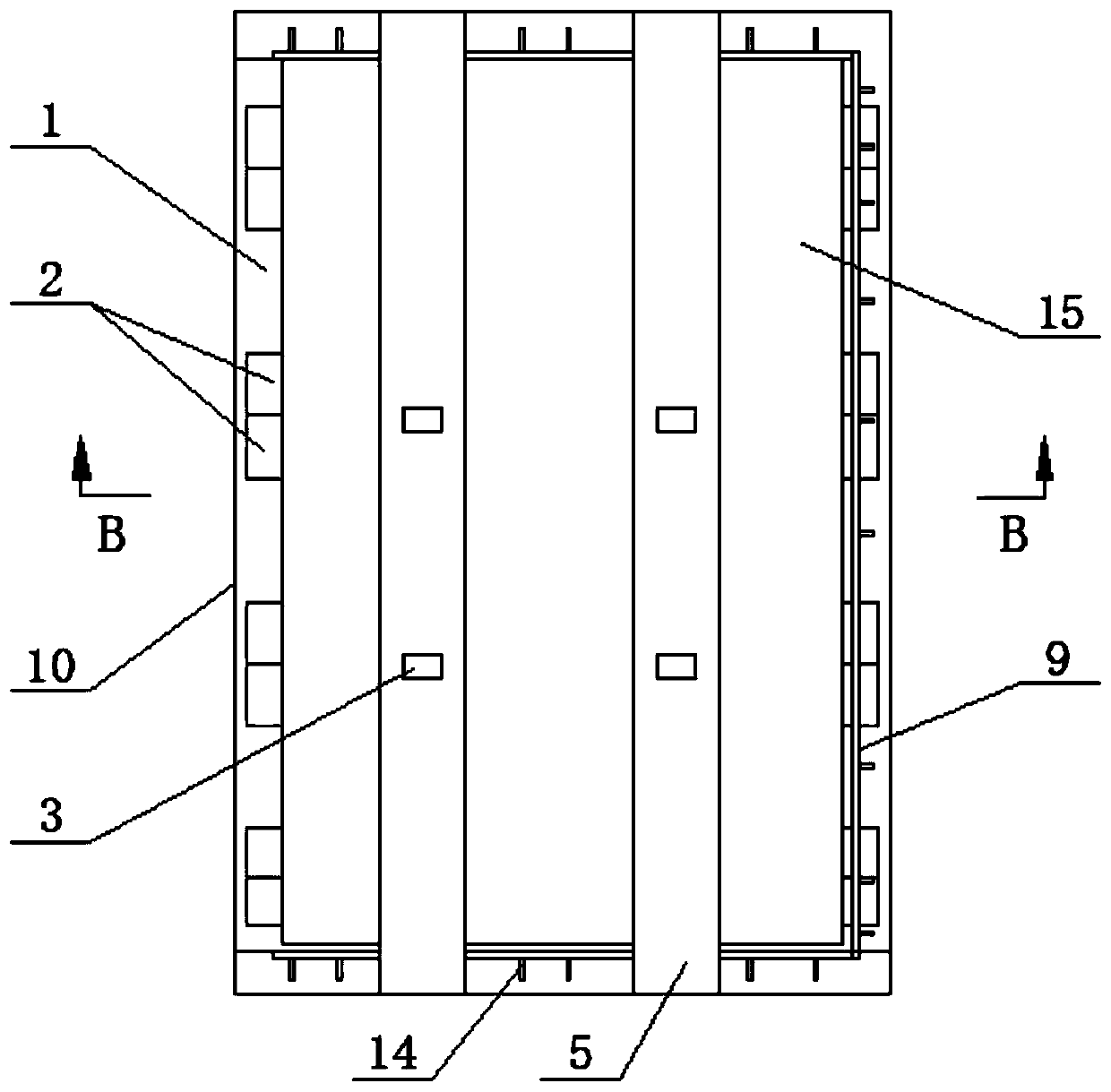

[0026] Specific embodiments, as described in the accompanying drawings Figure 1 to Figure 6 As shown, a kind of arc-shaped template rapid processing group membrane equipment includes a base 1 and a membrane pressing mechanism arranged on the base 1. The key is: the membrane pressing mechanism includes the shape of the upper surface and the bottom surface of the membrane The matching template 2 and the arc surface tightening mechanism 3 arranged above the template 2; the arc surface tightening mechanism 3 includes a bracket 4, a beam 5, a tightening screw 6 and a pressing block 7, and the bracket 4 Relatively arranged at both ends of the template 2, the height of the top of the bracket 4 is higher than the upper surface of the template 2, the beam 5 spans the template 2 and is fixed on the bracket 4 at both ends of the template 2, and the beam 5 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com