Device and method for mounting valve seat

A valve seat and hand technology, applied to hand-held tools, manufacturing tools, etc., can solve the problems of increased operation risk, increased hoisting operation, no benefit, etc., to achieve the effect of convenient operation, avoid hoisting operation, and save man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

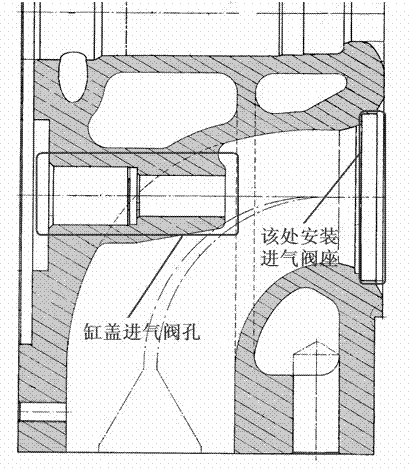

[0027] Below in conjunction with accompanying drawing and embodiment, the present invention is used for PC26 type cylinder head intake valve seat installation to be described in further detail, but can not limit the scope of protection of the present invention with this.

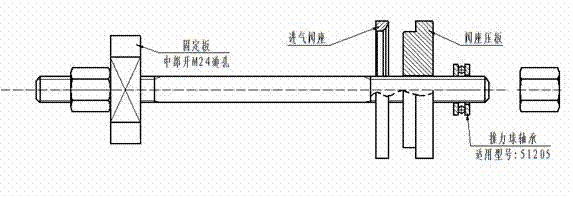

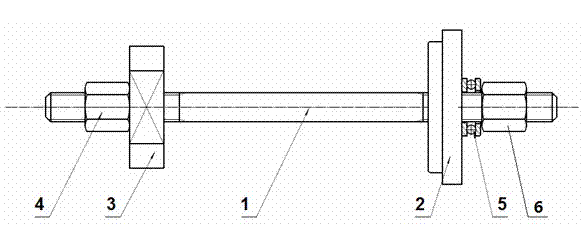

[0028] Please see first figure 2 , figure 2 It is a structural schematic diagram of the device for valve seat installation of the present invention. As shown in the figure, a device for valve seat installation includes a pull rod 1 with threads at both ends, a fixing plate 3 and a pressure plate 2 are respectively arranged at both ends of the pull rod 1, and the fixing plate 3 and the pressure plate 2 A first compression nut 4 and a second compression nut 6 are respectively installed on the outside of the outer side to fix the fixing plate 3 and the pressure plate 2 on both ends of the tie rod 1 . An axial ball bearing 5 is installed between the pressing plate 2 and the compression nut 4 outside the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com