Construction method of chemical ship pipe collecting area unit

A construction method and technology for a header area are applied in the field of construction of a chemical tanker header area unit, which can solve problems such as hidden safety hazards, unit deformation, and excessive work on board, so as to improve the overall weight of the unit, avoid unit structural deformation, and site layout. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

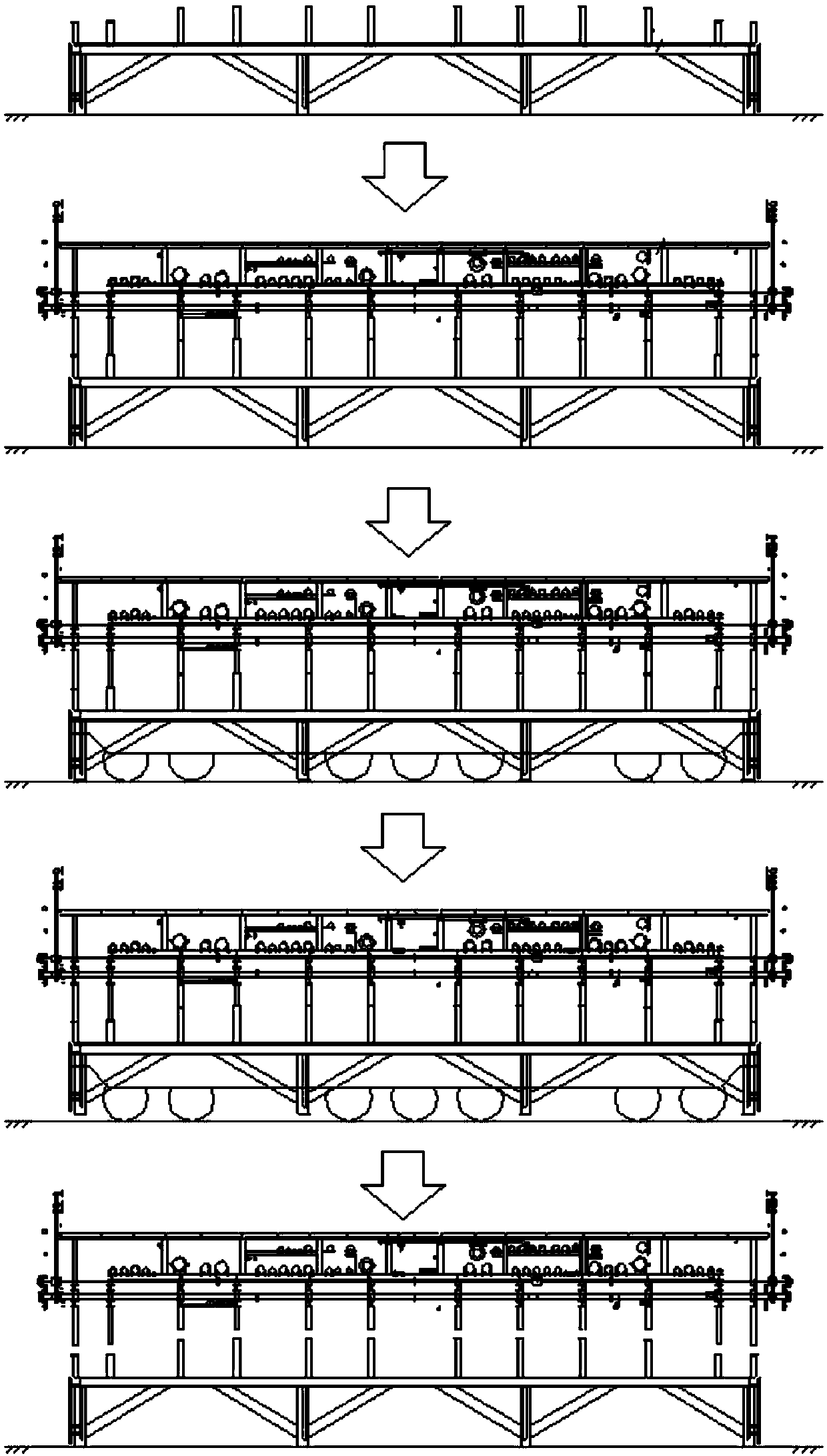

[0030] Below we will further elaborate on the construction method of the chemical tanker header area unit of the present invention in conjunction with the accompanying drawings and specific embodiments, in order to understand more clearly the construction process of the present invention and the structural composition and use of special tooling , but it cannot be used to limit the protection scope of the present invention.

[0031] The method of the present invention is a method specially designed for the construction and installation of the header area unit of a certain type of chemical tanker.

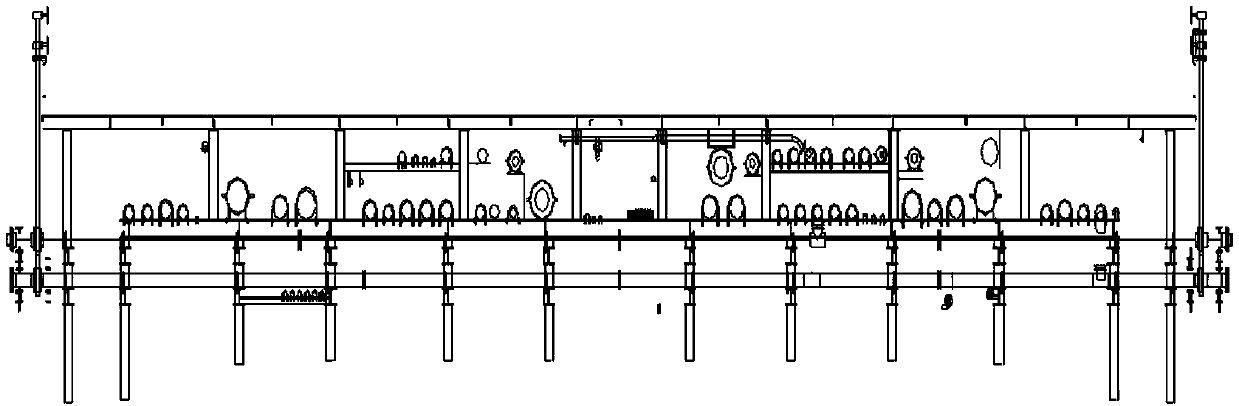

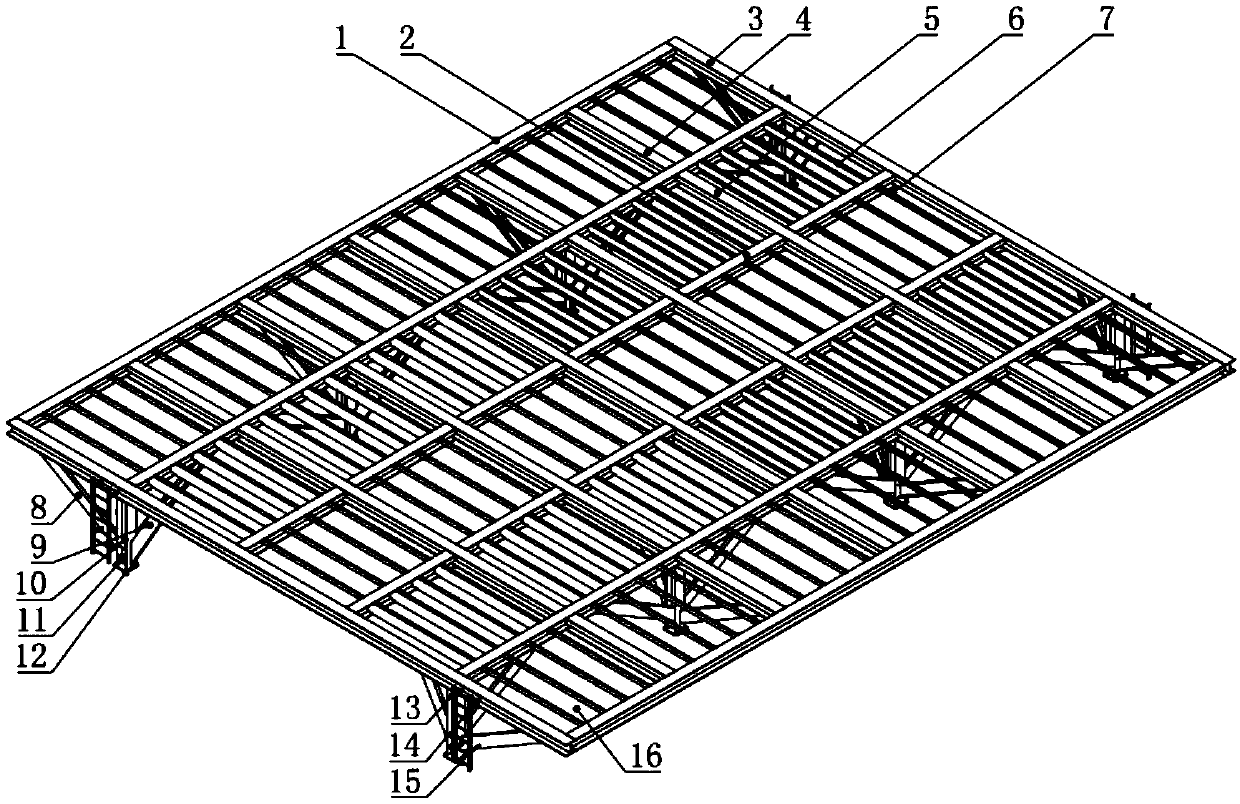

[0032] Such as figure 1 As shown, the unit structure of the header area on a certain type of chemical tanker includes two layers of supports, two layers of pipelines and platforms. Both the bottom bracket and the upper bracket are portal structures supported by beams and a plurality of uprights, the uprights of the bottom bracket are used as integral support points, the bottom pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com