Nuclear power station reactor internals anti-breaking assembly bottom plate measuring method

A measurement method and internal component technology, applied in geometric CAD, design optimization/simulation, etc., can solve problems such as waste of construction time, material resources, and increased safety and quality risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

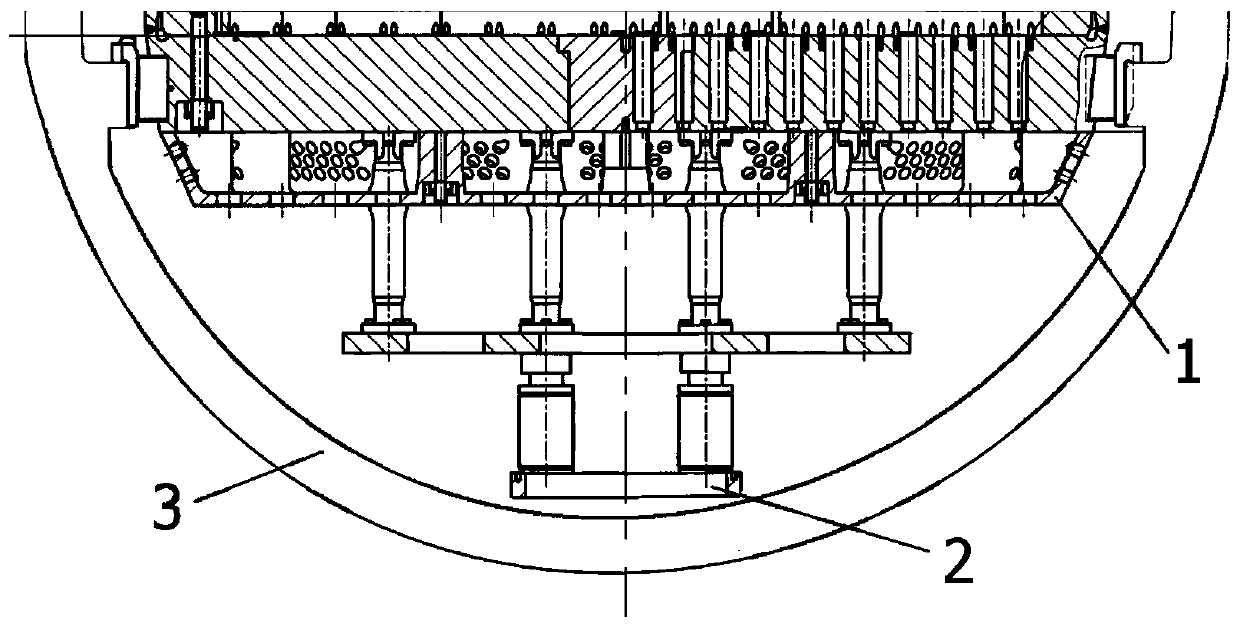

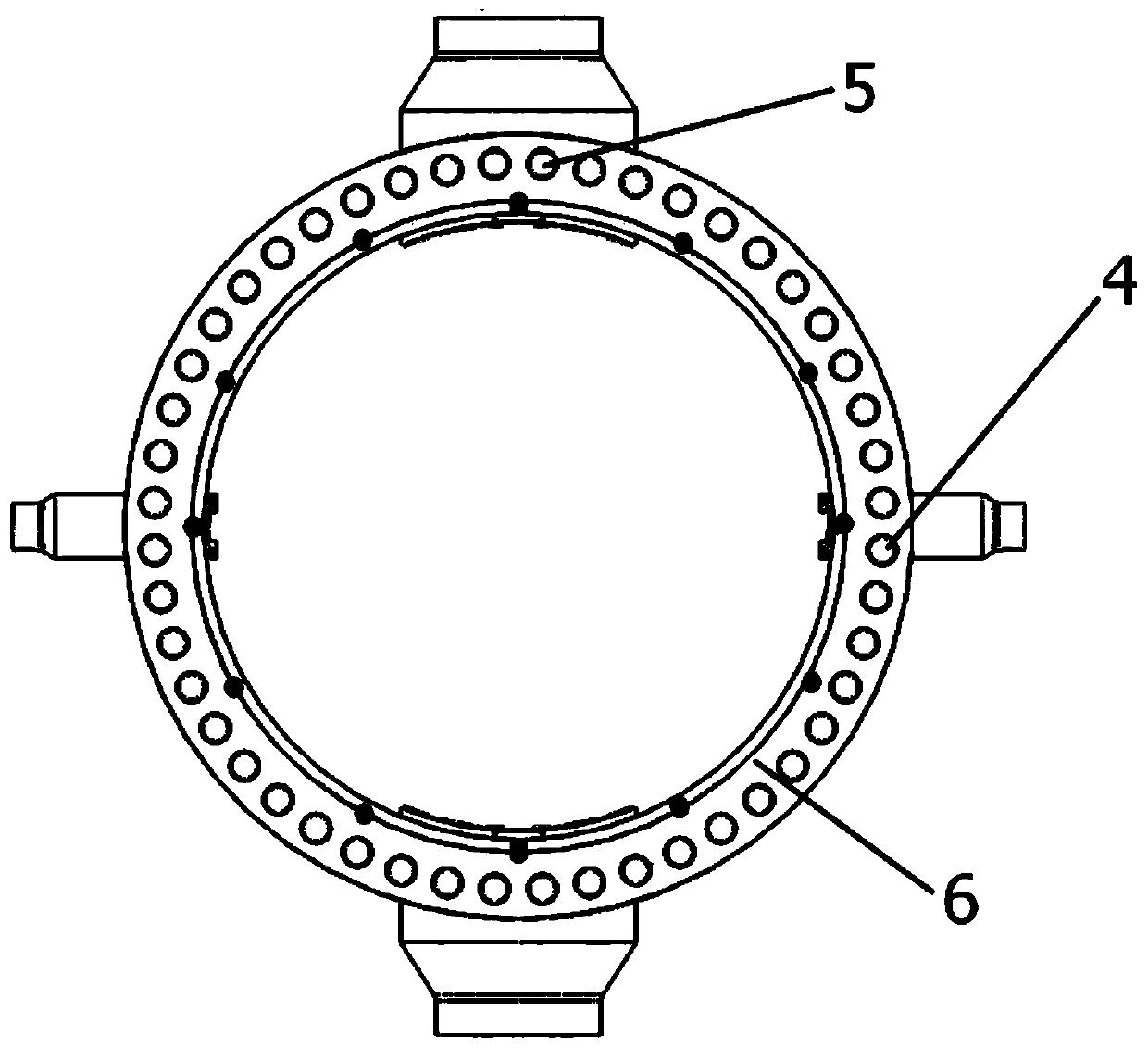

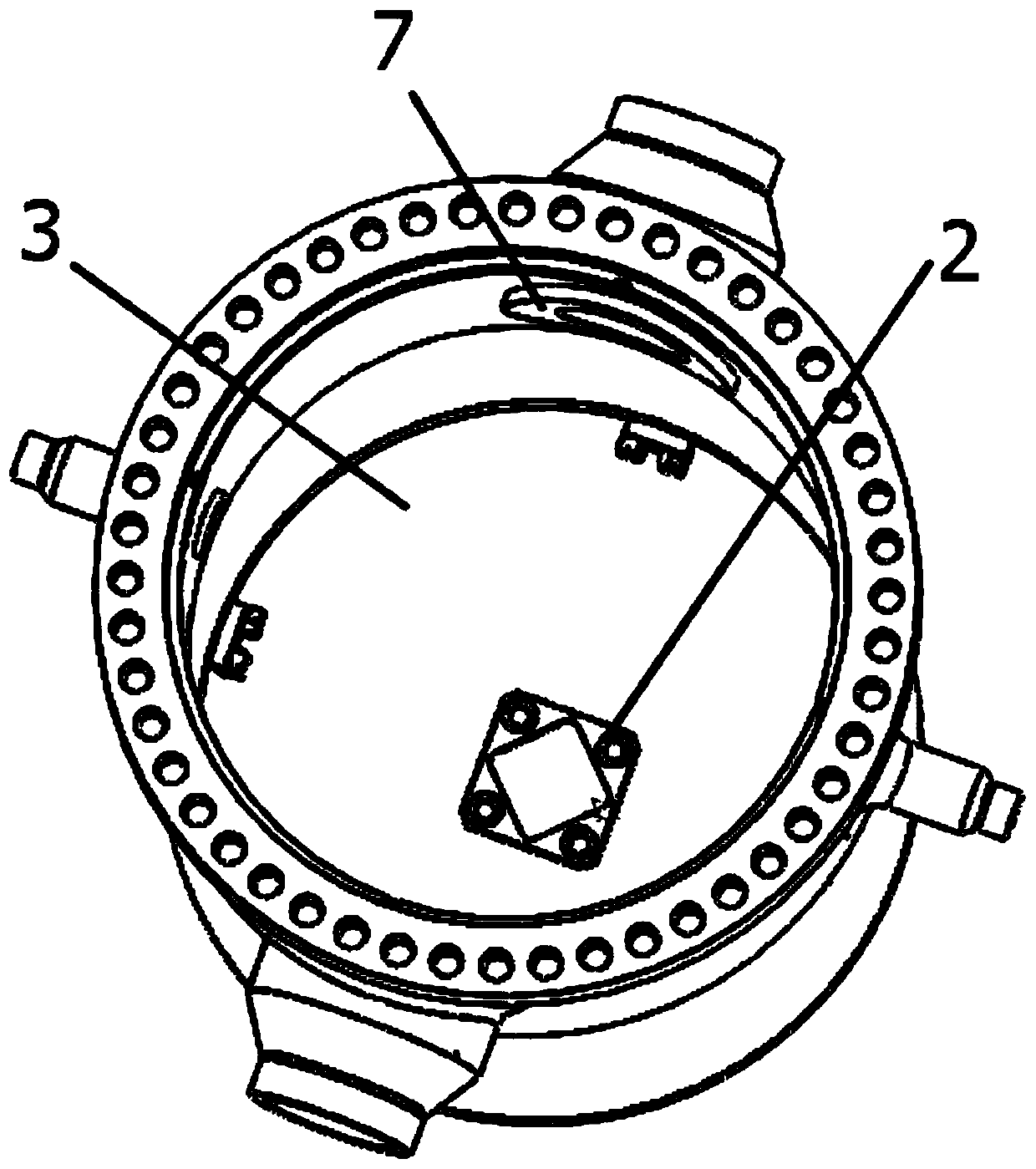

[0036] Combine below Figure 1-5 The method for measuring the bottom plate of the anti-break assembly of nuclear power plant internals of the present invention, specifically the method for measuring the distance between the bottom plate of the anti-break assembly of nuclear power plant internals and the bottom head of the pressure vessel, is described in detail.

[0037] 1) Establishment of pressure vessel coordinate system

[0038] Such as figure 1 , figure 2 As shown, after the pressure vessel is in place, the measurement control points are arranged on the wall of the refueling pool, and the control points are fixed with hot melt adhesive to ensure that the laser tracker can observe at least 6 measurement control points each time it is set up. The 25mm / 3mm cylindrical target base collects the measurement points on the top circumference of the No. 1 bolt hole 4 of the pressure vessel and the No. 37 bolt hole 5 of the pressure vessel, and measures 8 uniformly distributed me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com