Semi-automatic fixed die table PC component production system

A production system, semi-automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of manpower and material resources, difficult operation, expensive equipment, etc., achieve the effect of reducing labor intensity, avoiding hoisting operations, and good promotion prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

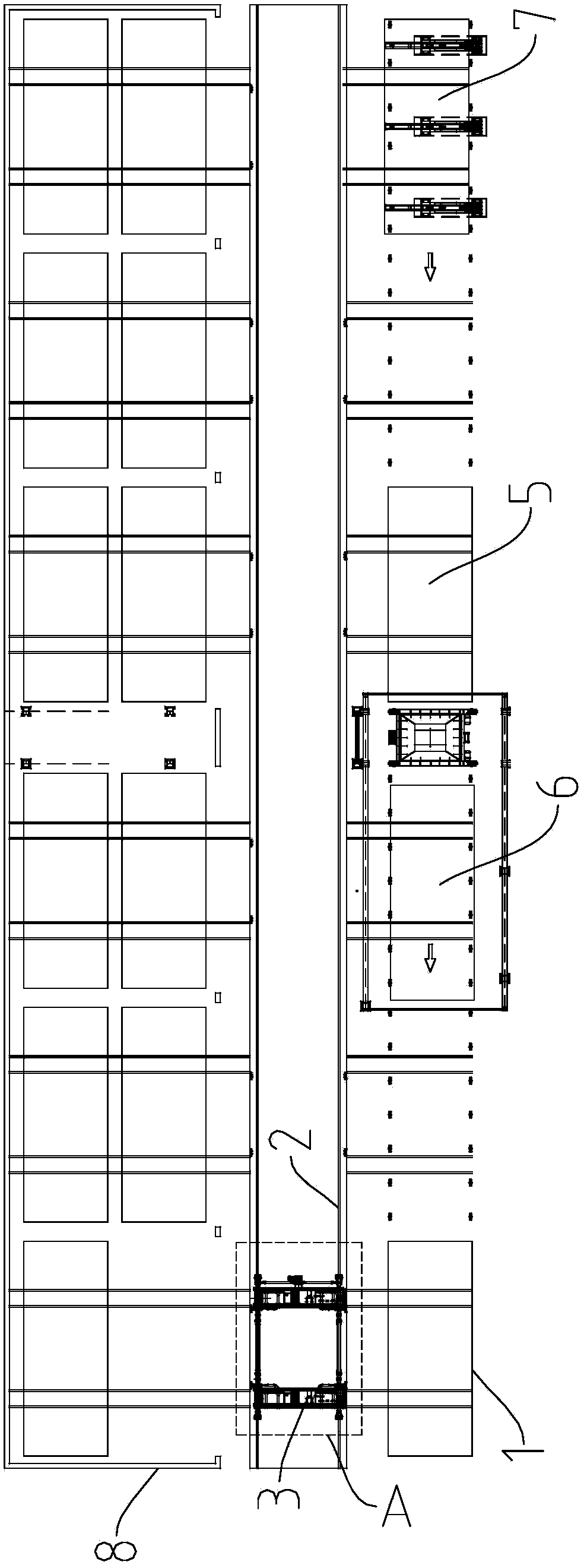

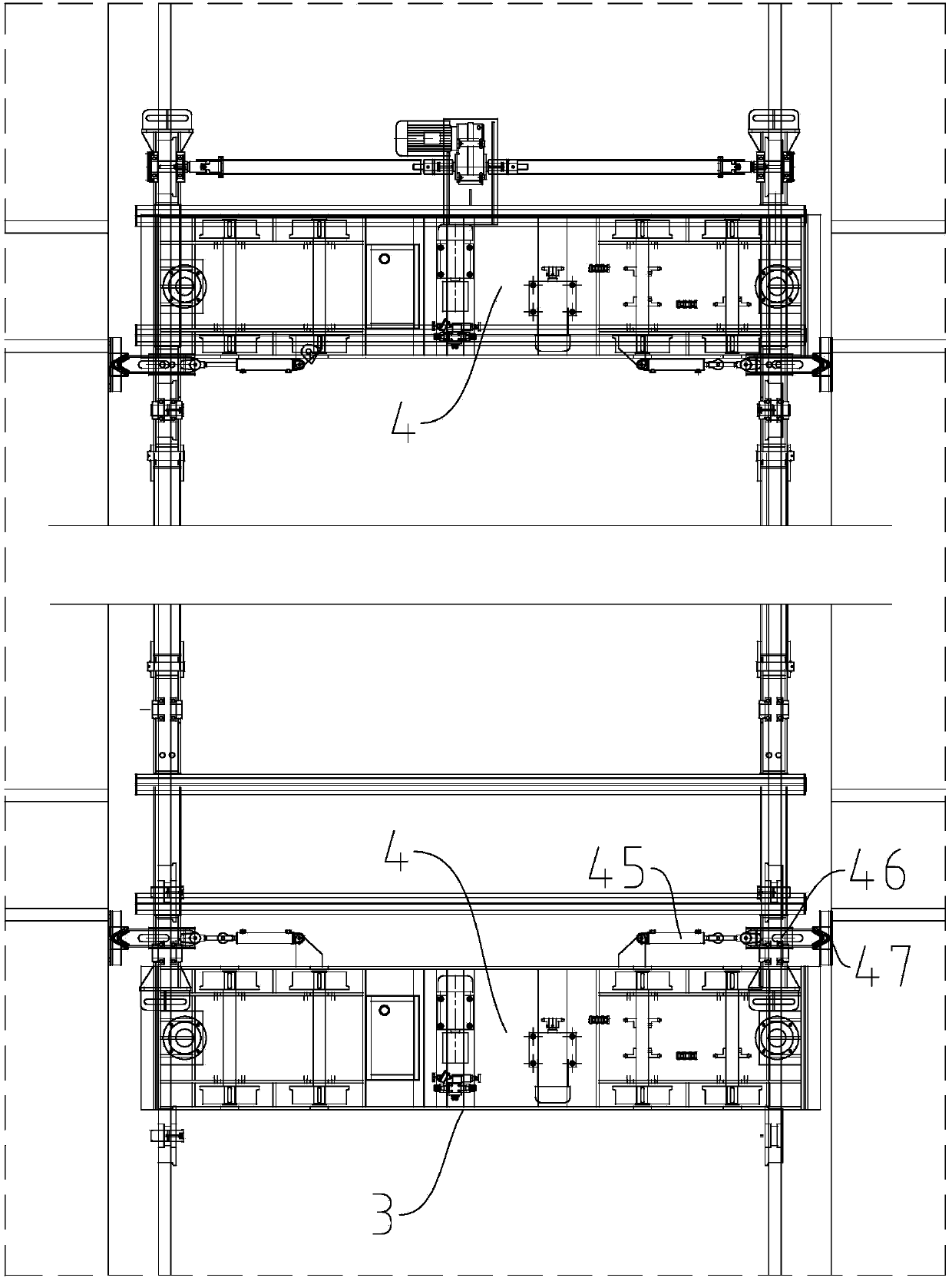

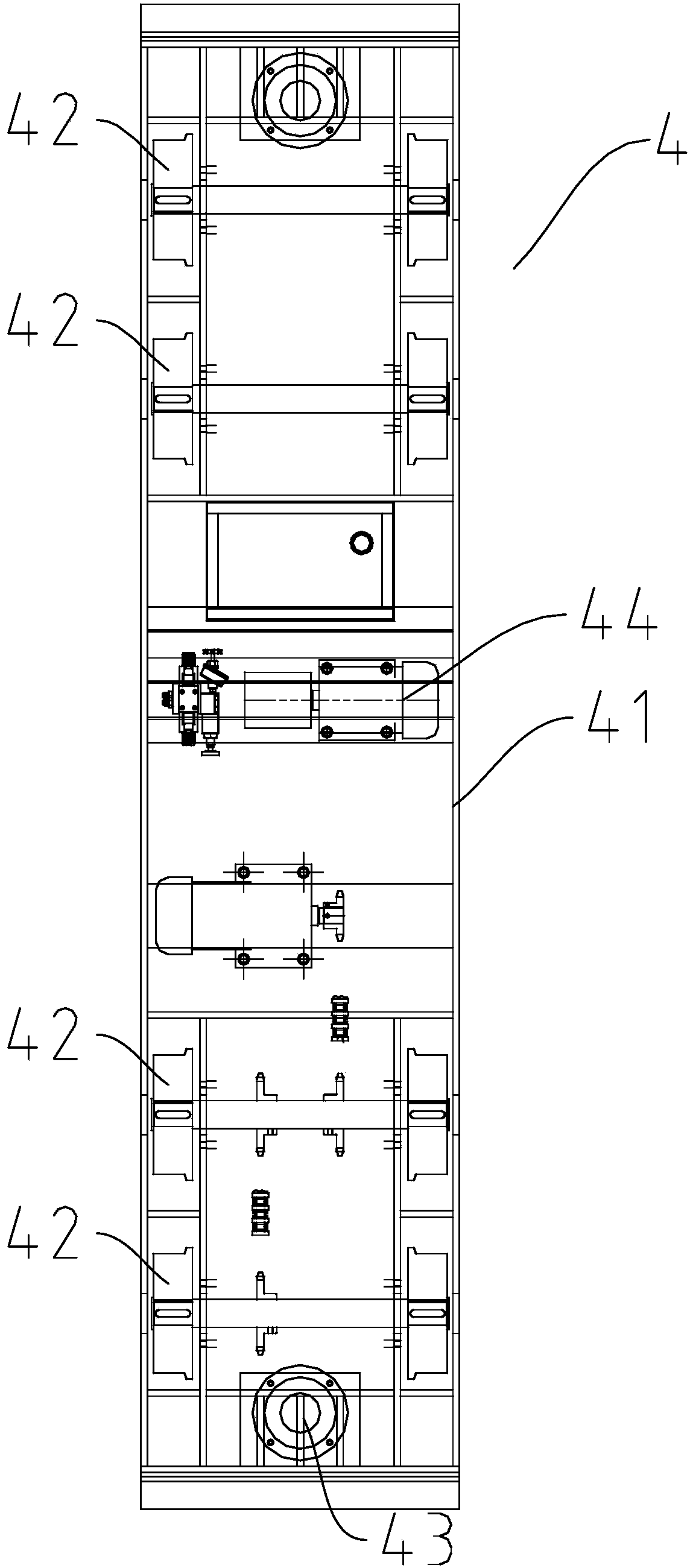

[0029] Figure 1 to Figure 3 It shows the semi-automatic fixed mold table PC component production system in some embodiments of the present invention. Compared with the general PC component production system, the PC component production system avoids frequent hoisting operations and greatly reduces the operator’s work. Labor intensity. Moreover, it can effectively reduce the number of hoisting equipment, occupy space, etc., and has huge advantages and good promotion prospects.

[0030] refer to figure 1 , the semi-automatic fixed mold table PC component production system includes a mold table 1, a first guide rail 2, a traveling vehicle 3, and an operating station and a maintenance station.

[0031] In some embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com