A spliced light steel wall board and a light steel building composed of the light steel wall board and the light steel building

A splicing and wall panel technology, applied to walls, building components, buildings, etc., can solve the problems of many assembly operations, high labor intensity, and inconvenient transportation, and achieve the effects of fast assembly, simplified construction technology, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

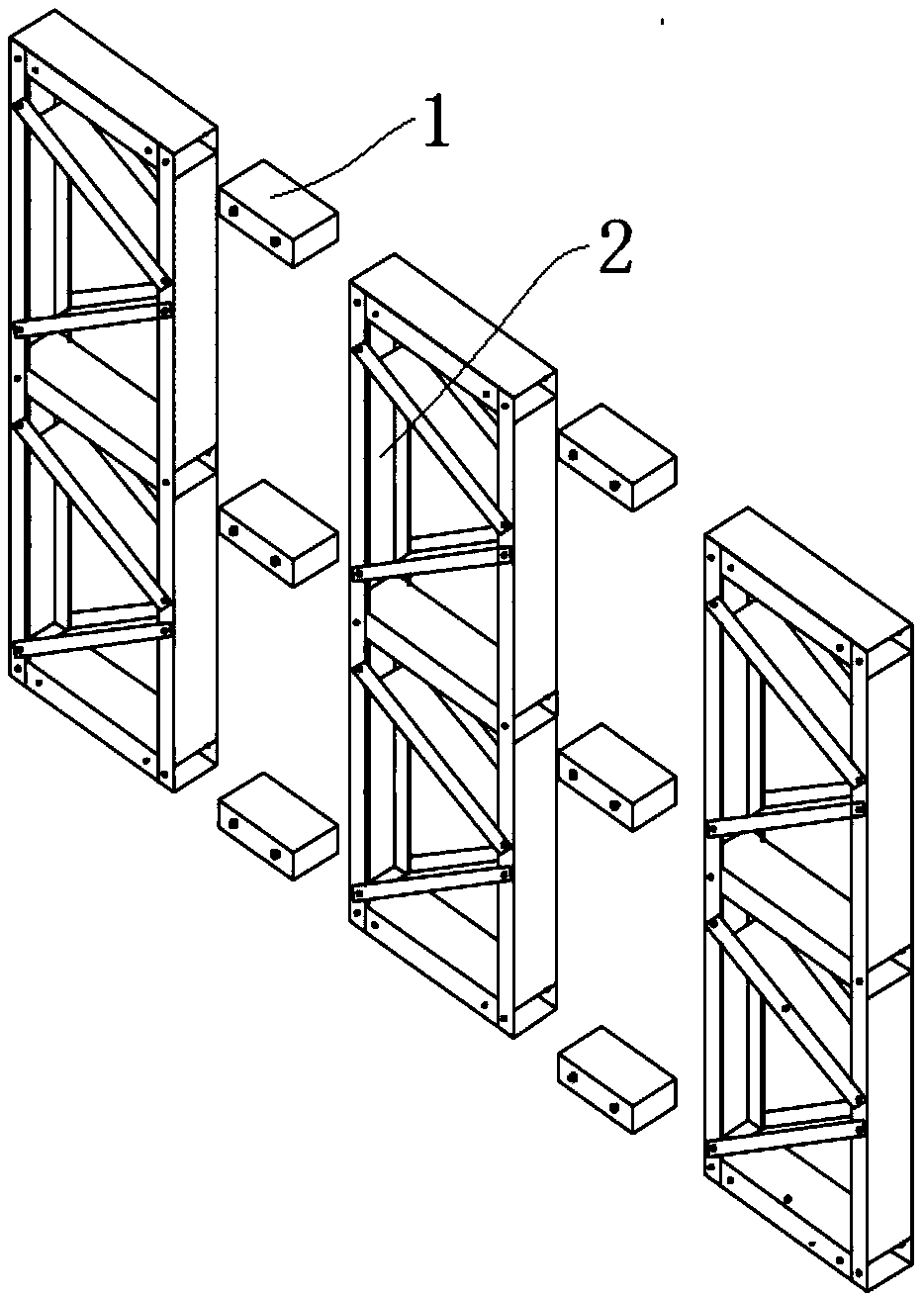

[0029] combine figure 1 , a spliced light steel wall panel in this embodiment includes a wall panel body, and the wall panel body is formed by splicing one or two kinds of modular wall sections. The one-shaped mortise 1 is spliced and fixed, and the structure is simple. The wall sections are made according to the needs, and the wall sections are quickly assembled by the mortise to form a wall panel. The transportation is convenient, the on-site assembly is fast, the construction process is simplified, the cost is reduced, and the construction progress is improved. , and reduce the technical requirements for construction personnel; the wall panel body is spliced by a modular wall section, the modular wall section is the standard wall section 2, and the size of the standard wall section 2 is diversified according to specific needs Setting, the standard wall section 2 includes light steel keels arranged horizontally at the top, middle and bottom; between the standard wall s...

Embodiment 2

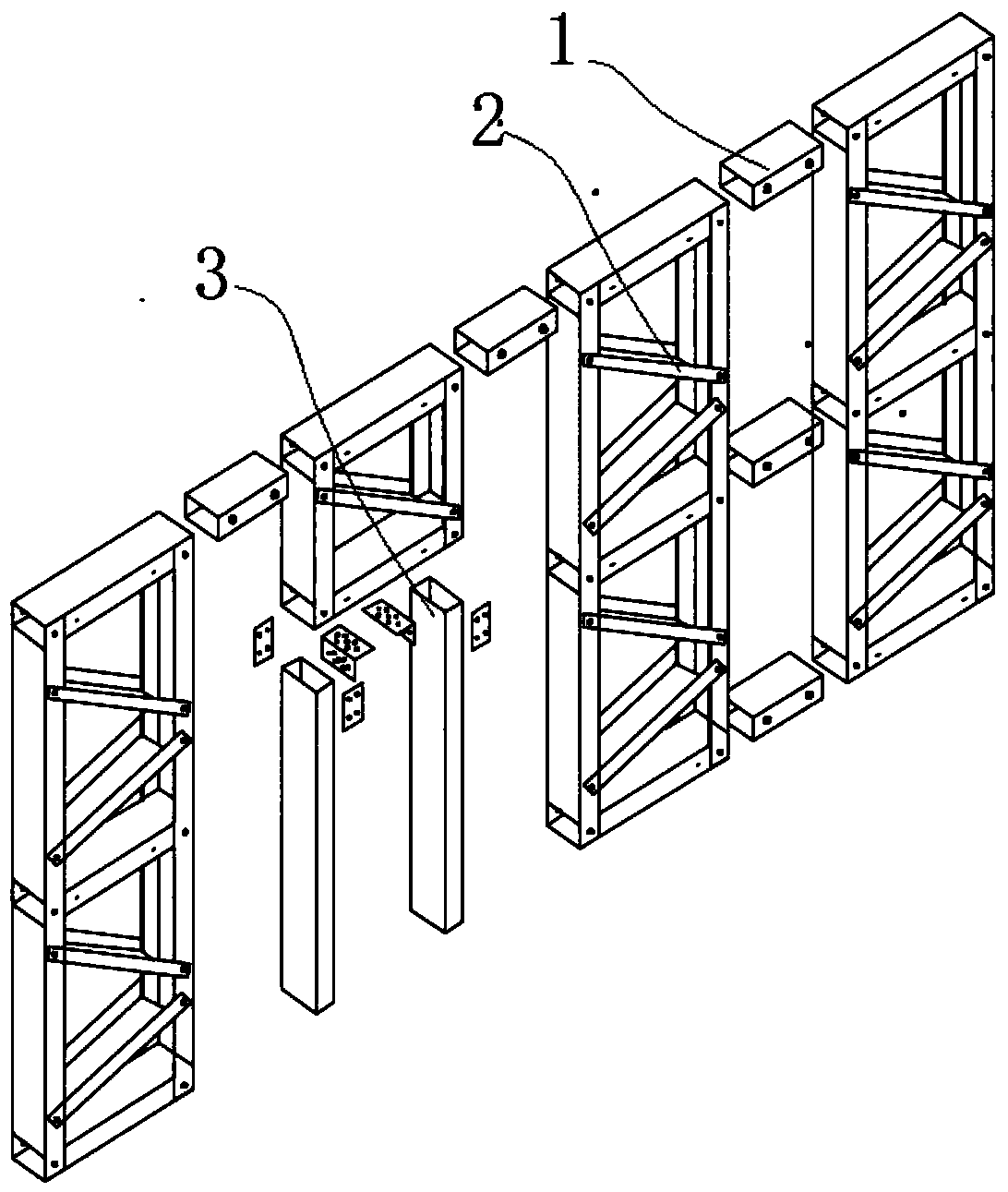

[0031] combine figure 2 , the basic structure of a spliced light steel wall panel of this embodiment is the same as that of Embodiment 1, the difference is that the wall panel body is spliced by two kinds of modularized wall sections, and the modularized wall sections are respectively It is the standard wall section 2 and the door opening wall section 3. The sizes of the standard wall section 2 and the door opening wall section 3 are diversified according to specific needs. The standard wall section 2 includes light steel keels at the top, middle and bottom; the door opening wall Section 3 includes light steel keels arranged horizontally at the top and middle, and the standard wall sections 2 described in adjacent two sections are spliced and fixed by the inline tenon 1 arranged at the top, middle and bottom of the standard wall section 2 , the standard wall section 2 and the door opening wall section 3 are spliced and fixed through the inline tenon 1 arranged on the ...

Embodiment 3

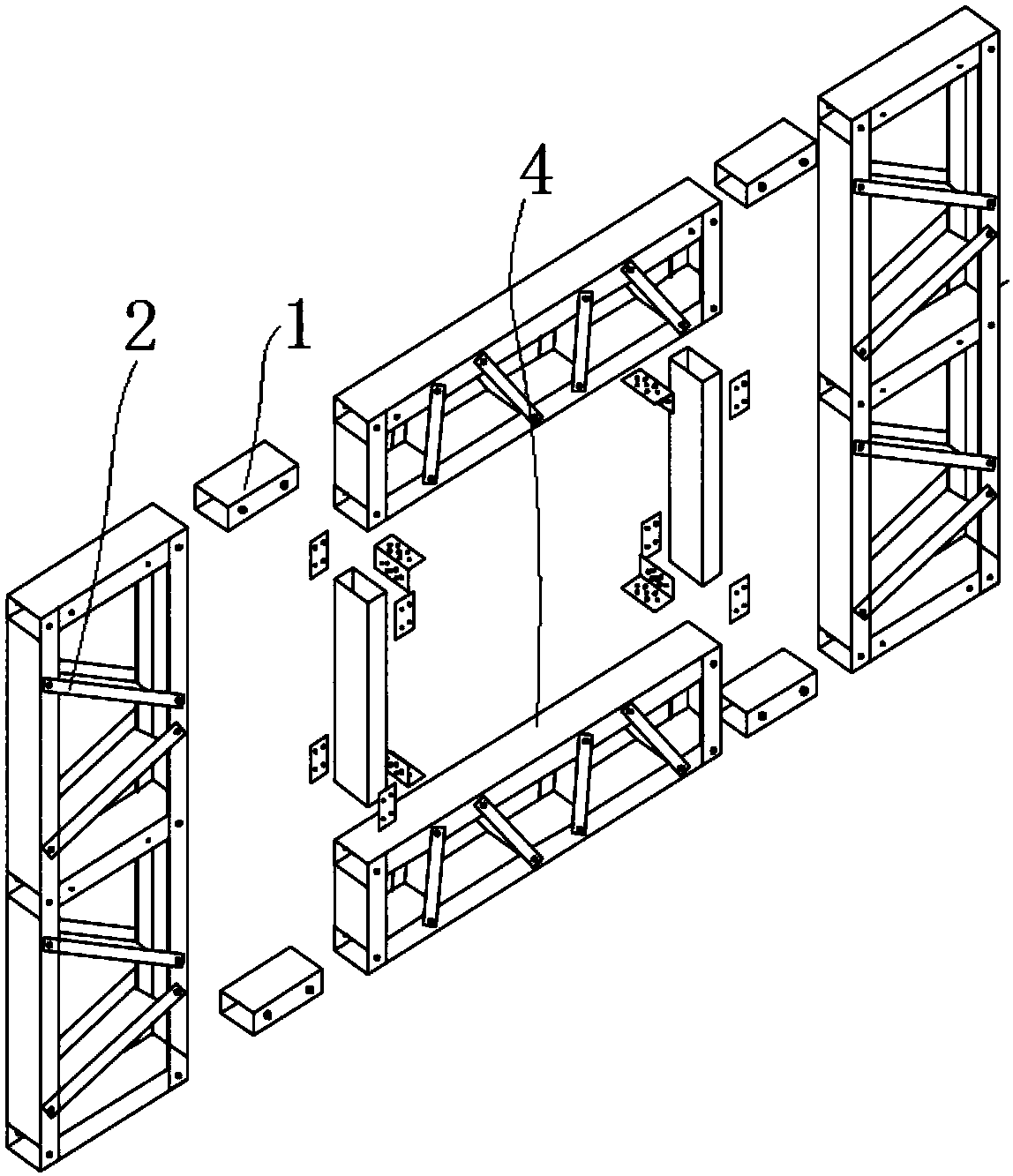

[0033] combine image 3 , the basic structure of a spliced light steel wall panel of this embodiment is the same as that of Embodiment 1, the difference is that the wall panel body is spliced by two kinds of modularized wall sections, and the modularized wall sections are respectively It is the standard wall section 2 and the window opening wall section 4. The sizes of the standard wall section 2 and the window opening wall section 4 are diversified according to specific needs. The standard wall section 2 includes light steel keels at the top, middle and bottom. The standard wall sections 2 mentioned in the paragraph are spliced and fixed by the inline tenons 1 arranged at the top, middle and bottom of the standard wall sections 2, and the window opening wall section 4 includes light steel keels at the top and bottom , the standard wall section 2 and the window opening wall section 4 are spliced and fixed through the top and bottom of the window opening wall section 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com