Patents

Literature

40results about How to "Avoid complex construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

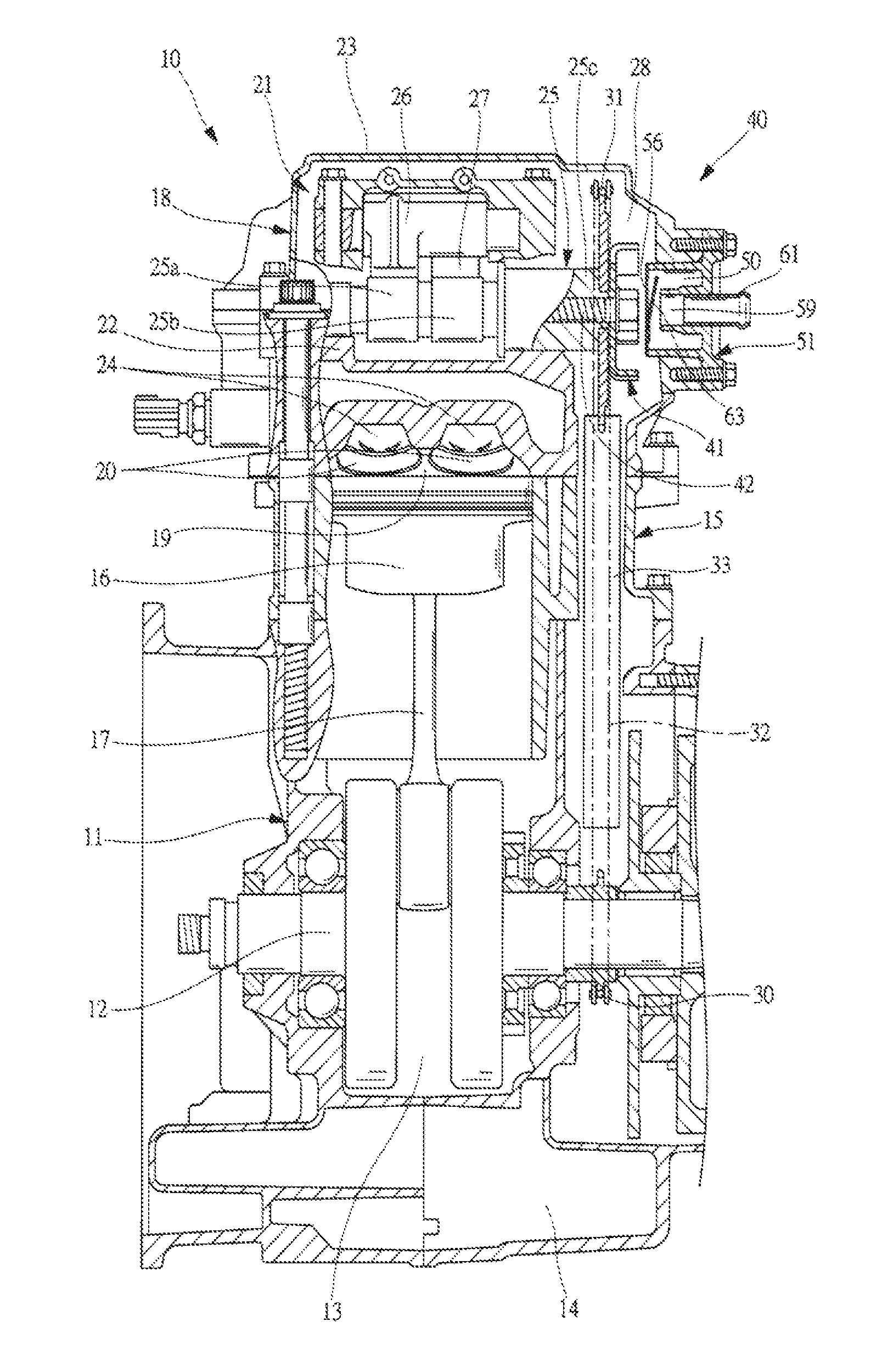

Power tool

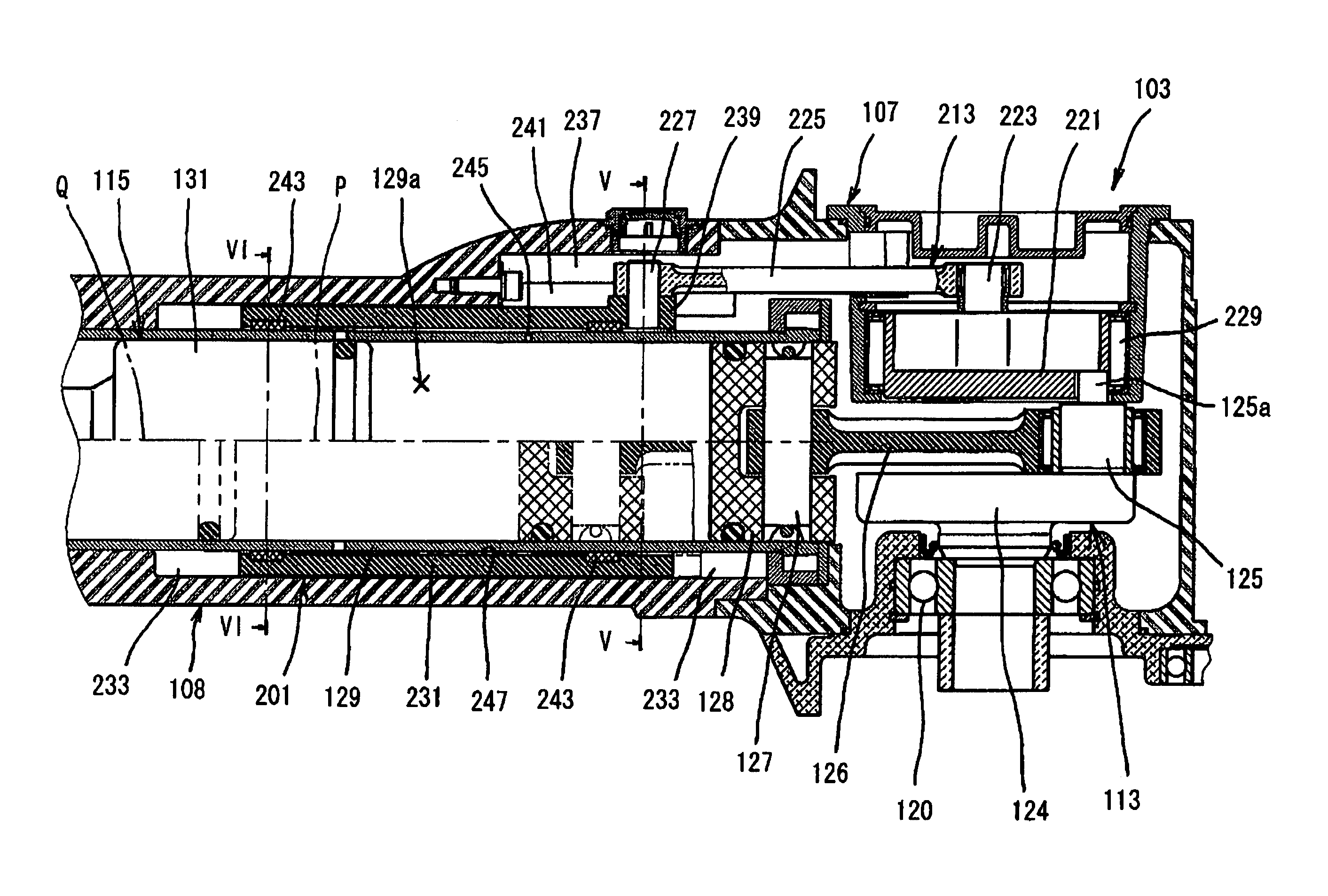

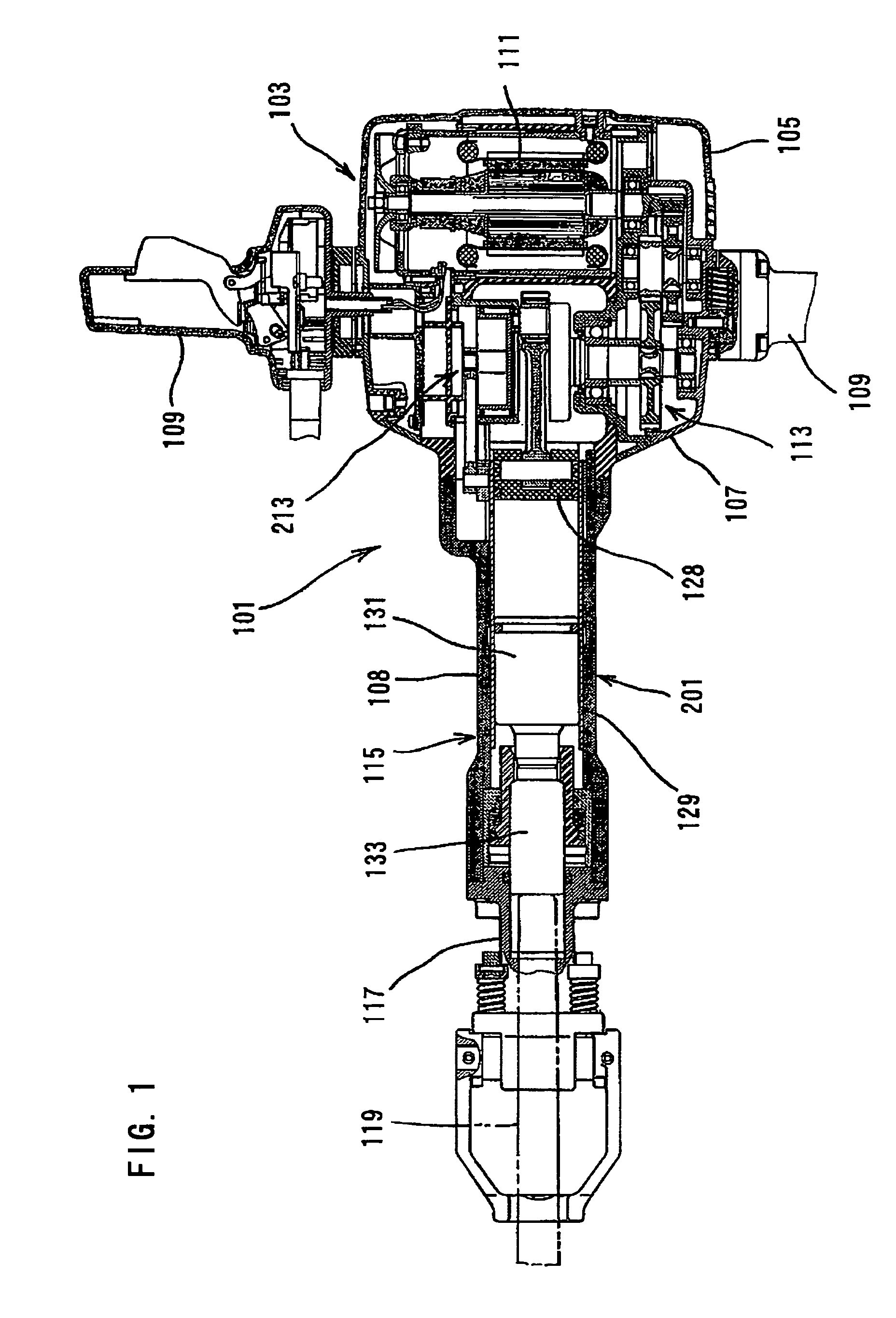

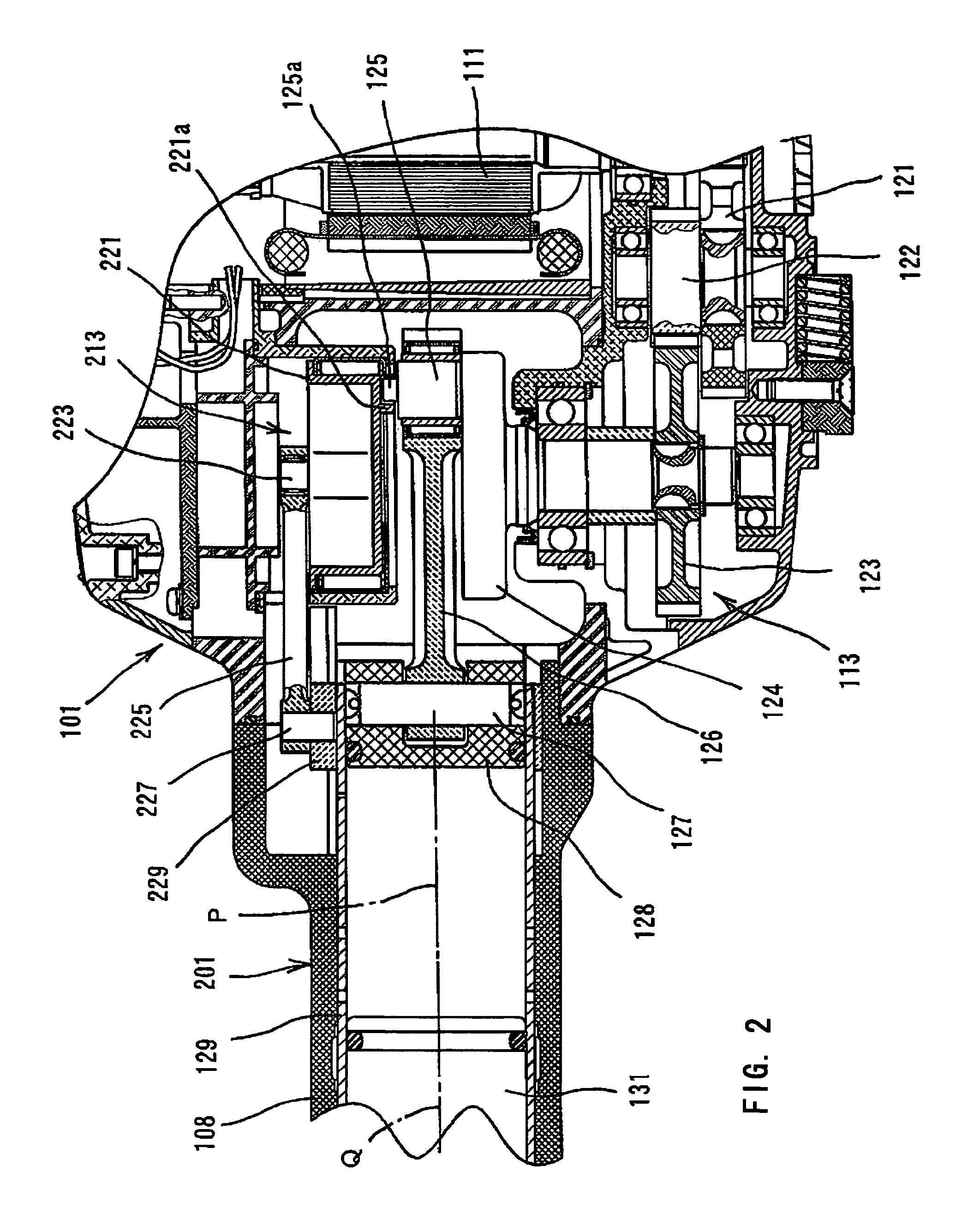

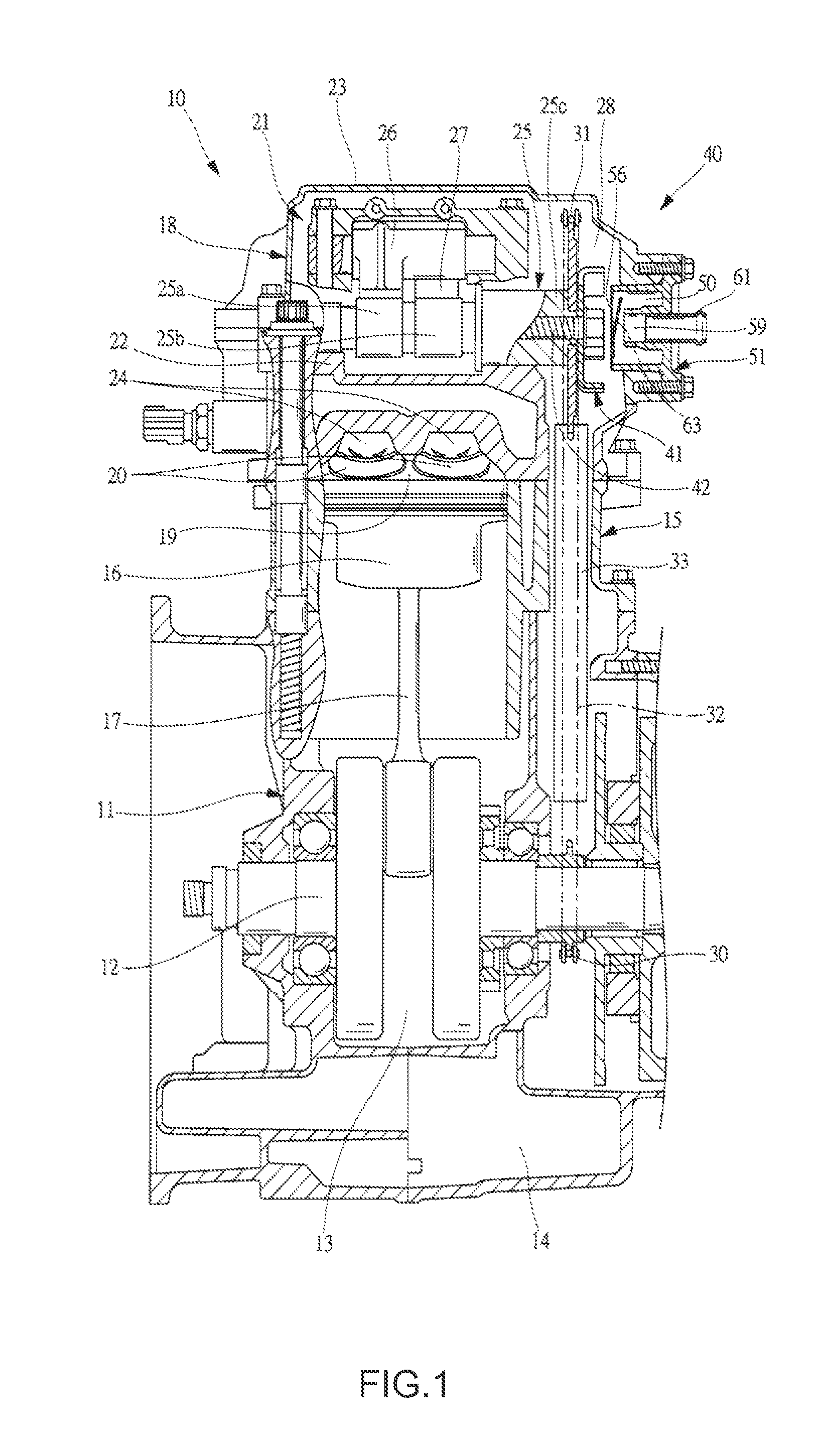

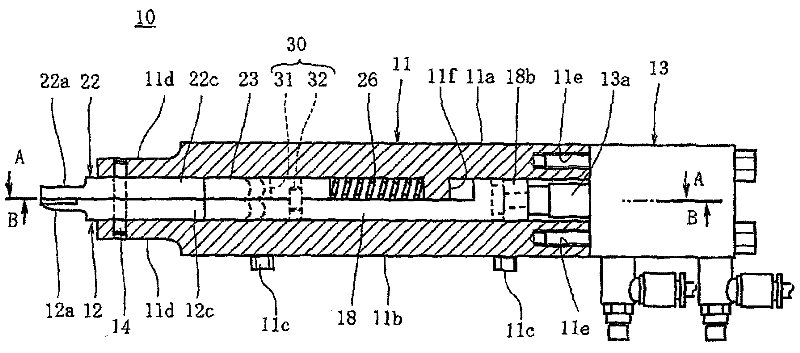

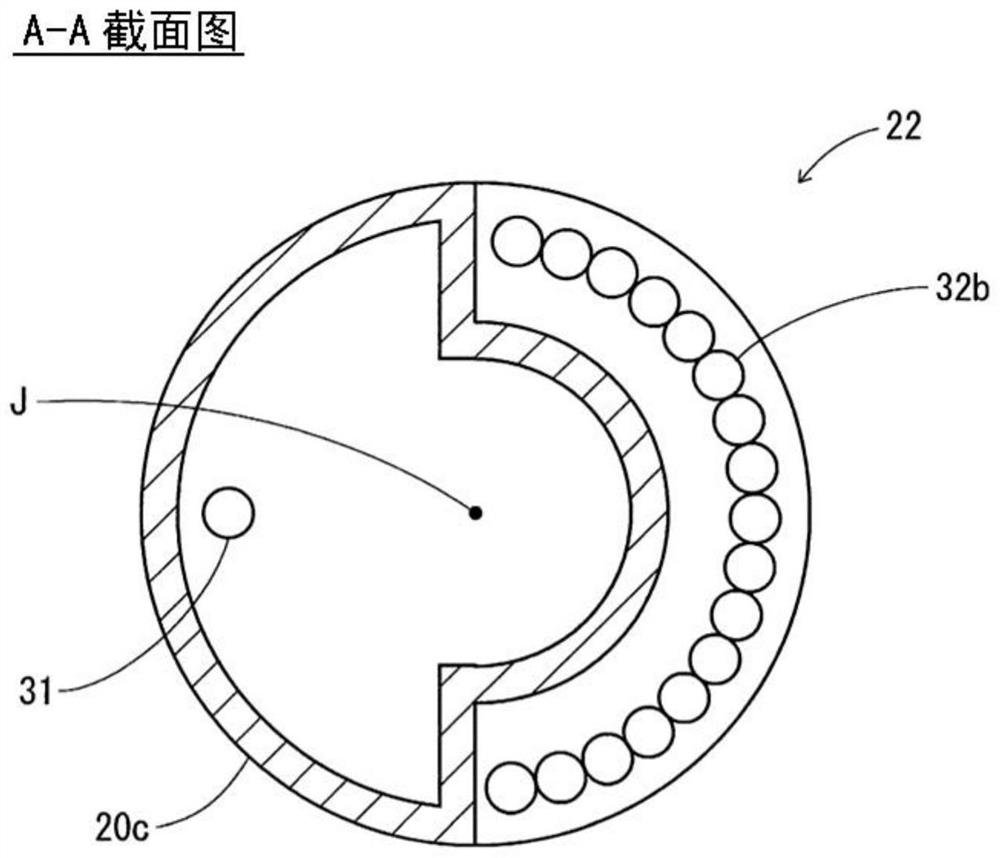

ActiveUS7096973B2Improve vibration damping effectAvoid complex constructionReciprocating drilling machinesPortable percussive toolsReciprocating motionEngineering

It is an object of the invention to provide a technique for further improving the vibration reducing performance in the power tool, while avoiding complicating the construction of the power tool. According to the present invention, a representative power tool may comprise a striker, a tool bit and a vibration reducer. The vibration reducer serves to reduce vibration on the striker by reciprocating in a direction opposite to the reciprocating direction of the striker. The path of the center of gravity of the vibration reducer is arranged to coincide with a path of the center of gravity of the striker. With such construction, because rotating moment is not exerted onto the reciprocating cylinder during the operation of the power tool, vibration reduction can be performed in a stable manner.

Owner:MAKITA CORP

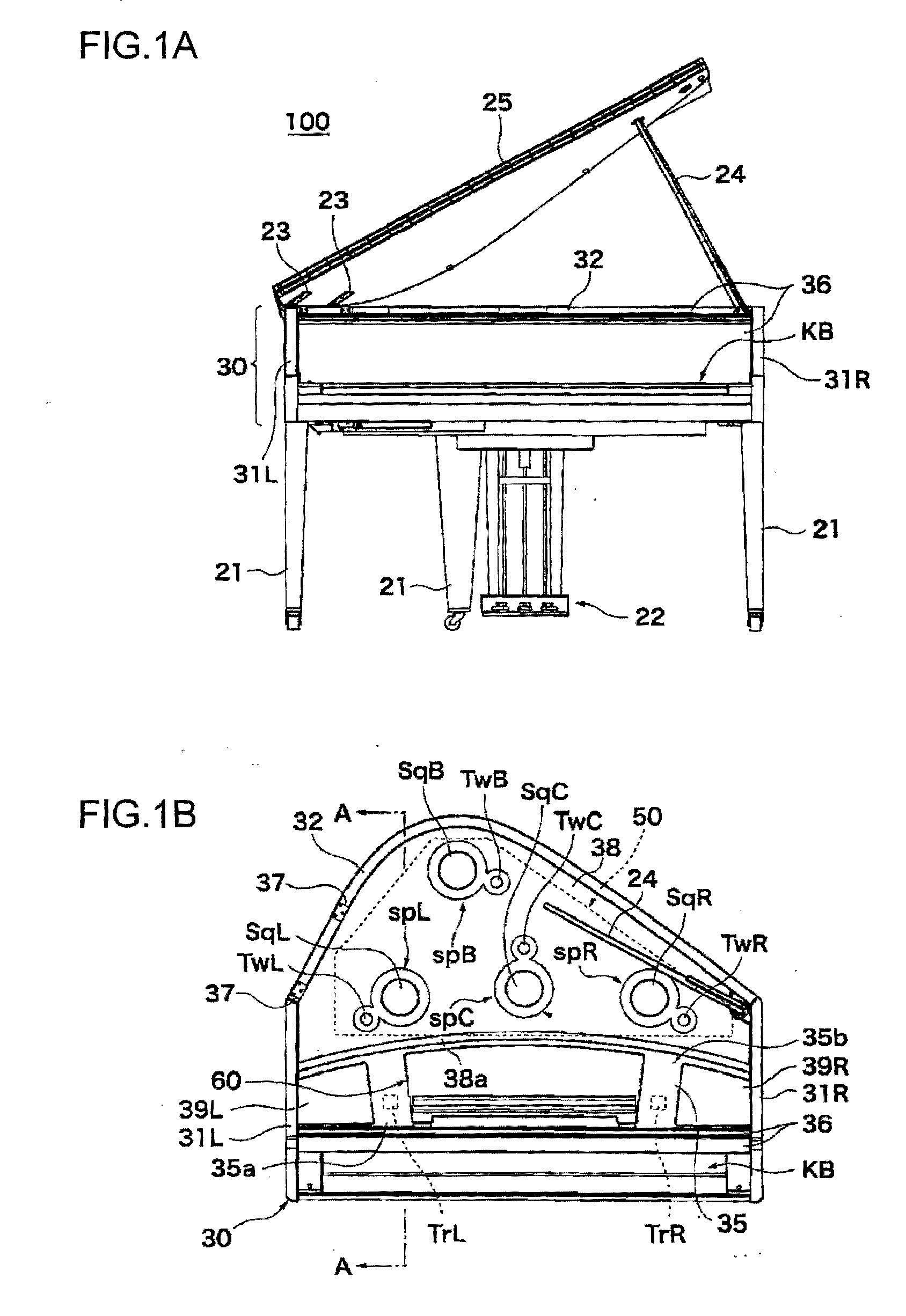

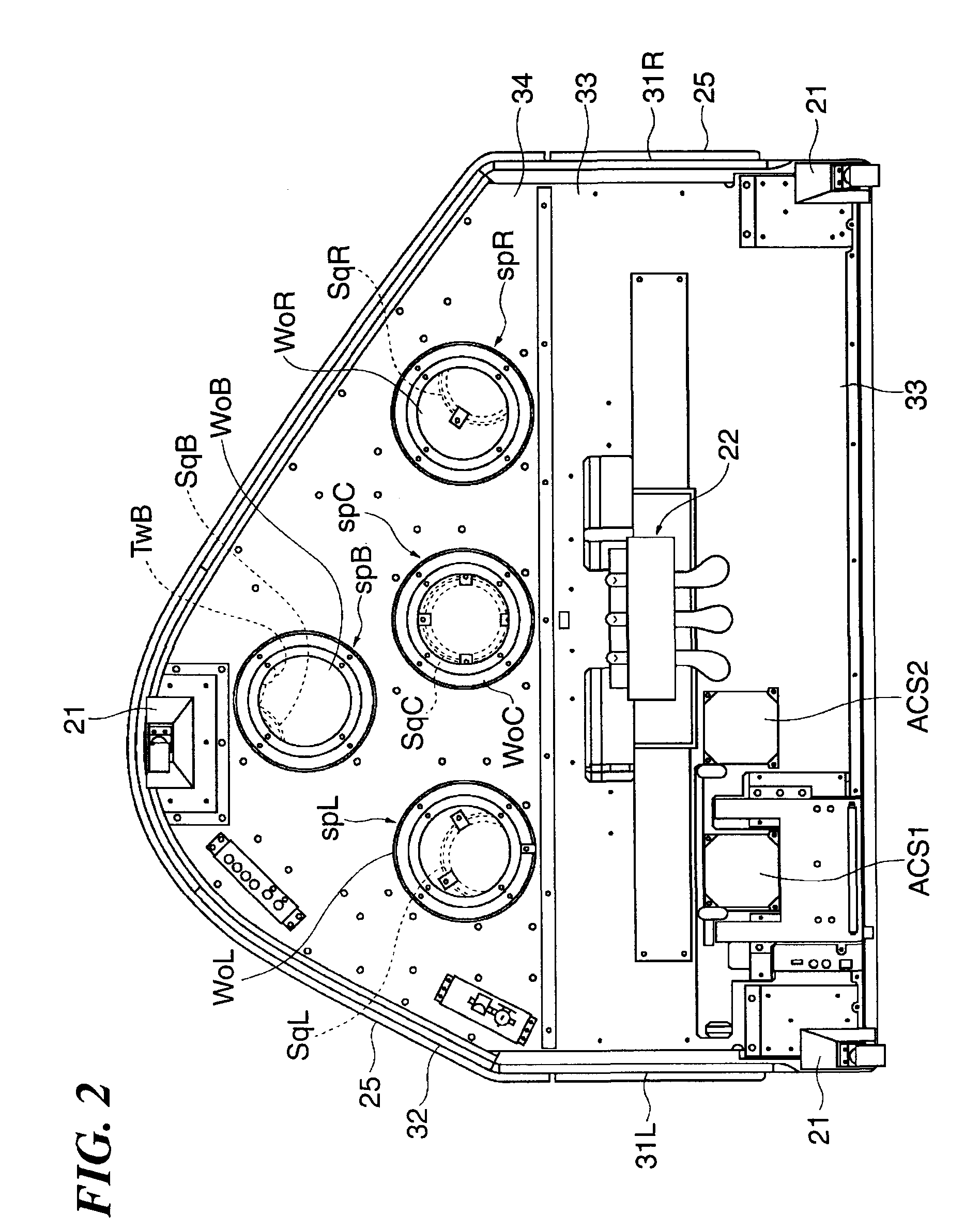

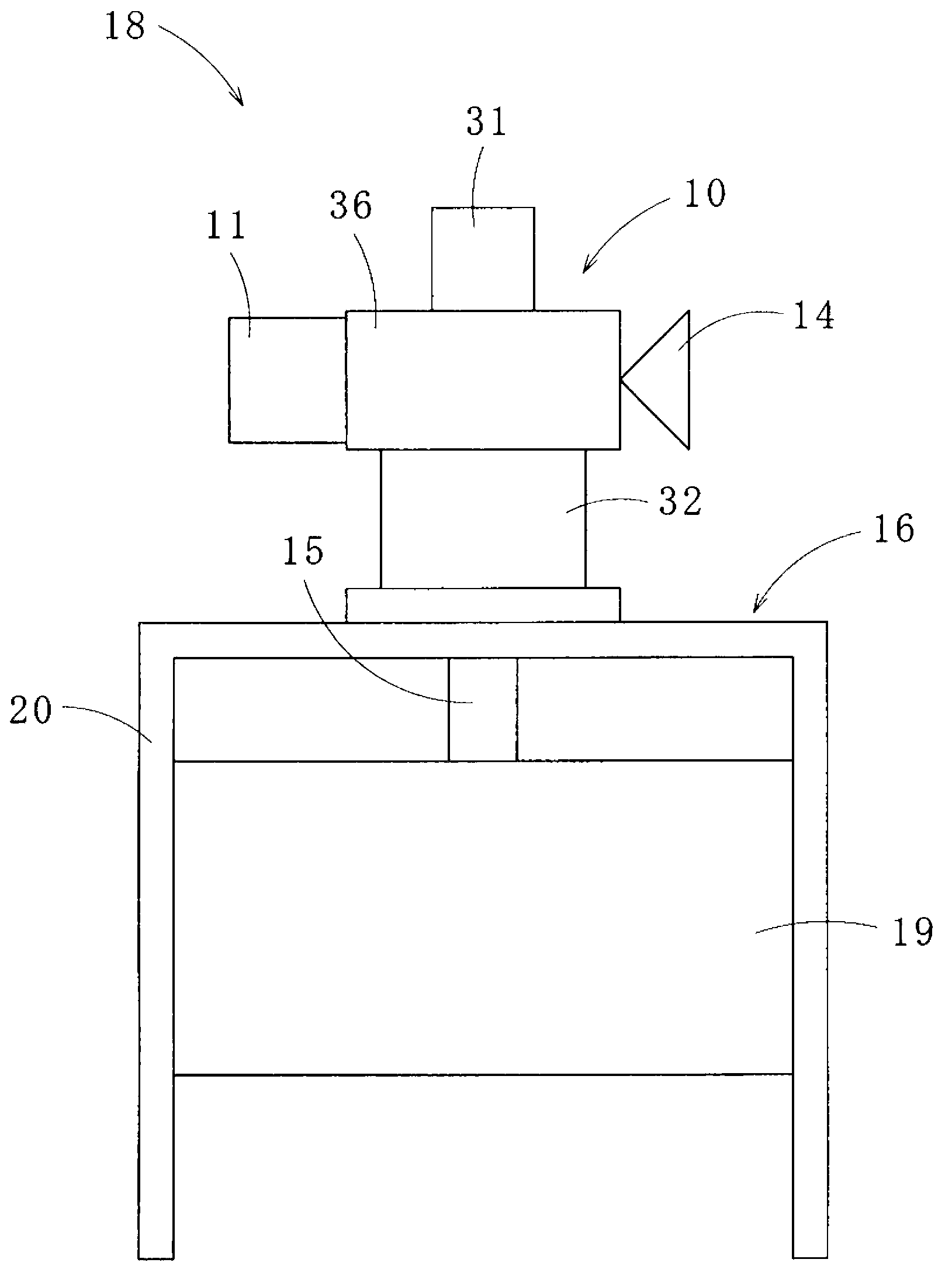

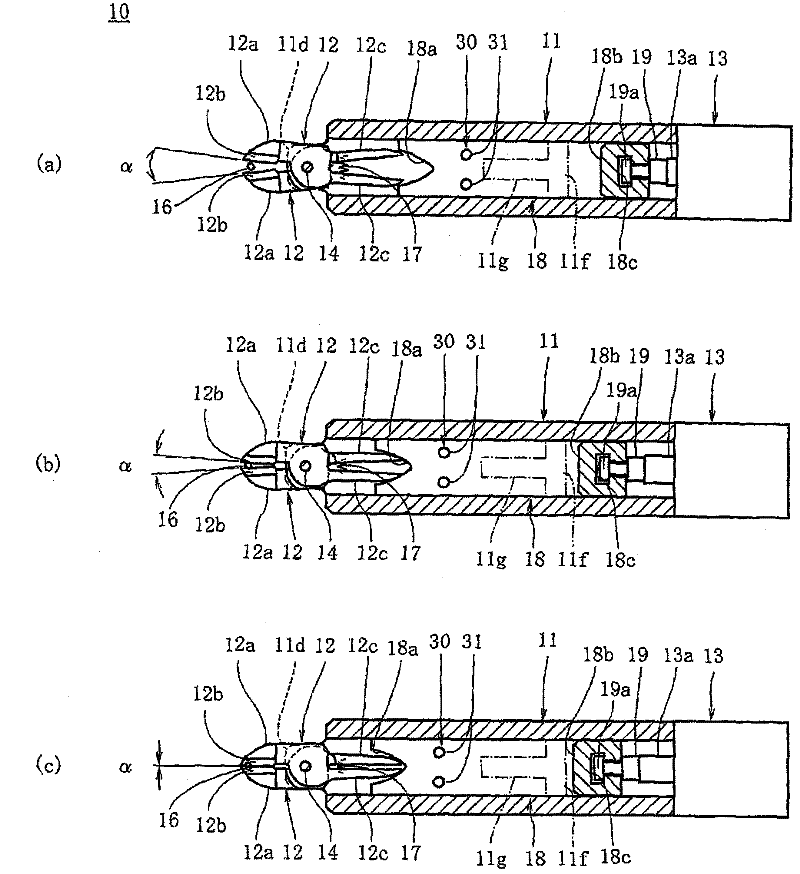

Electronic keyboard instrument

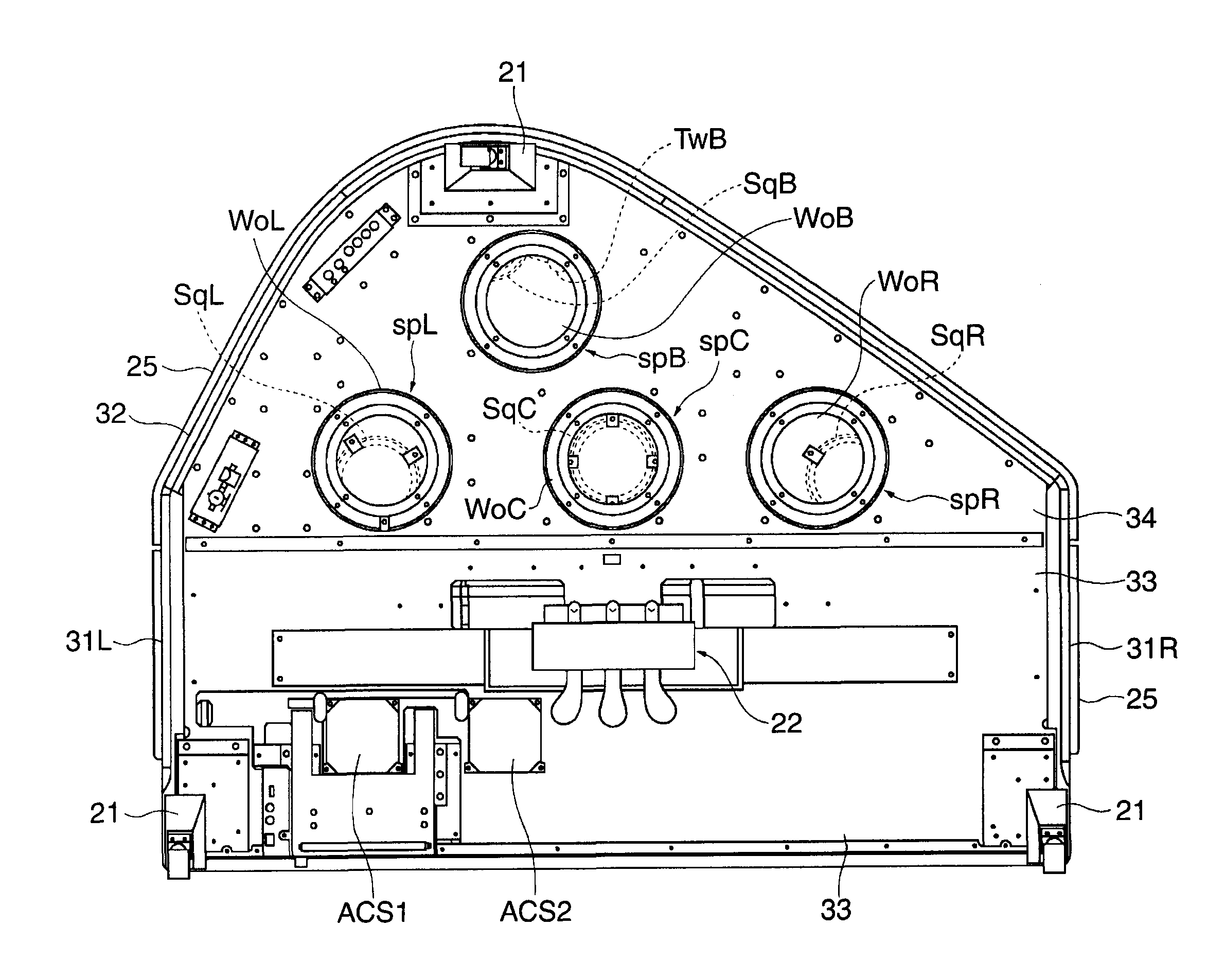

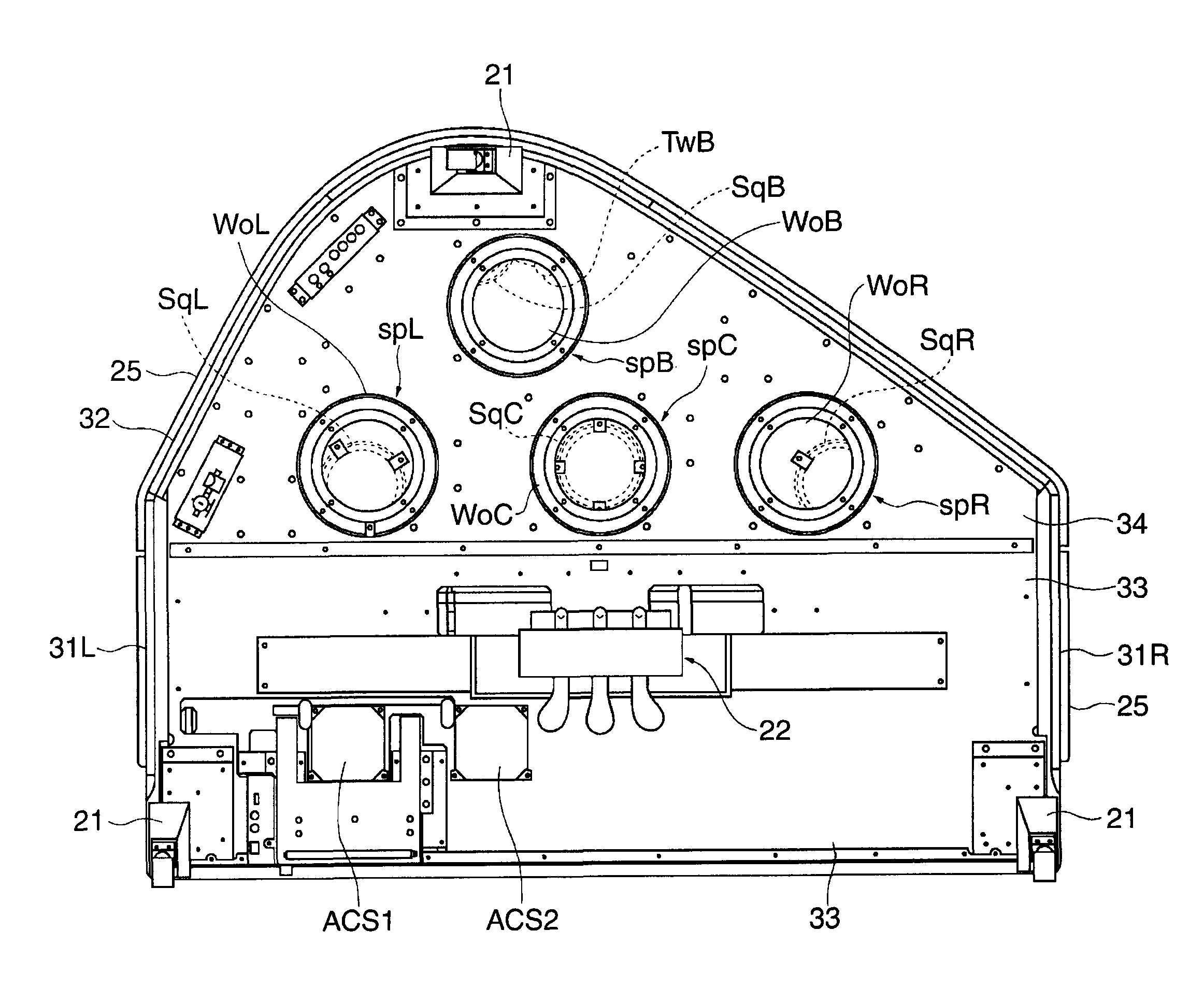

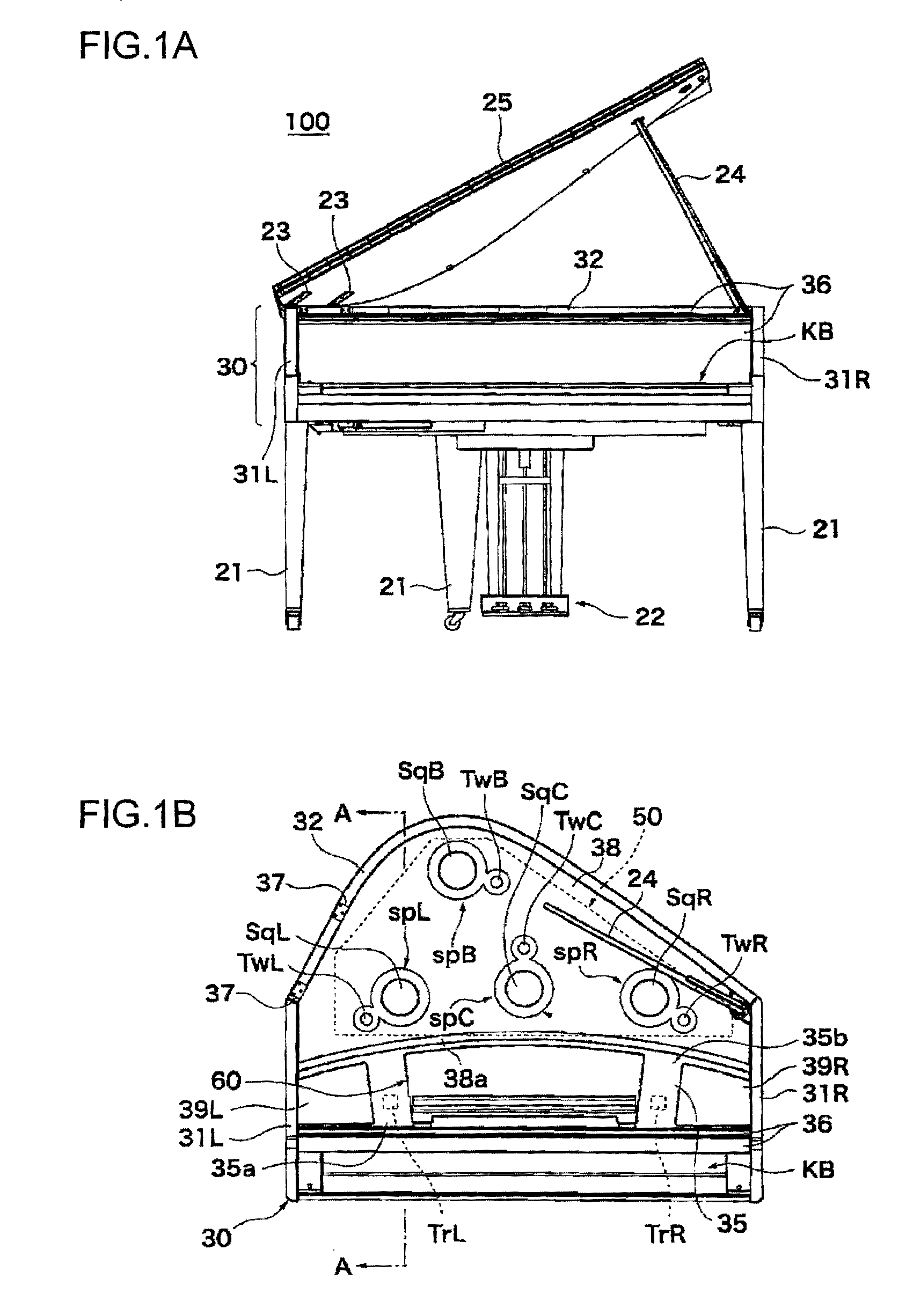

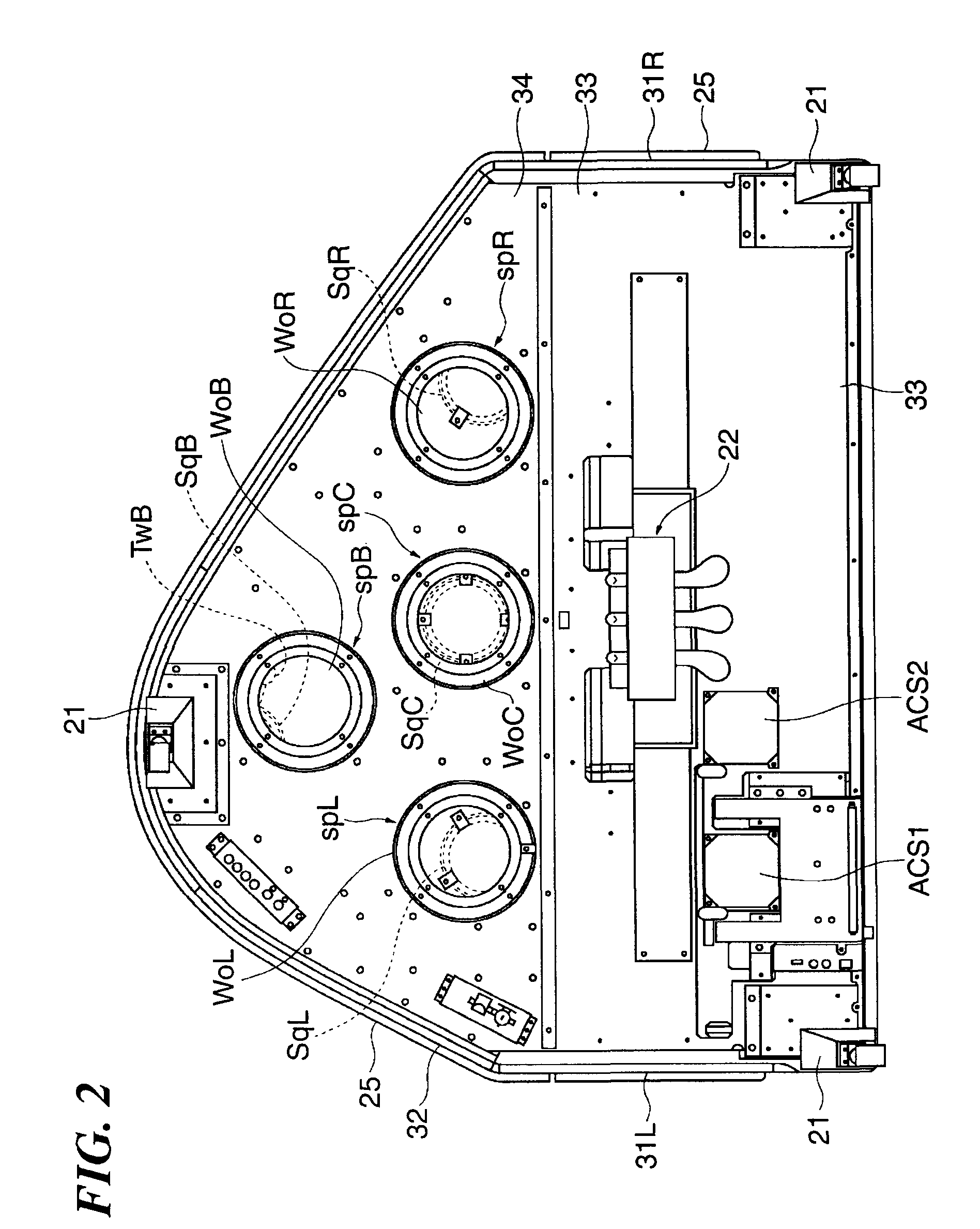

ActiveUS20100192756A1Avoid complex constructionImprove distributionElectrophonic musical instrumentsStringed musical instrumentsInterior spacePiano

An electronic keyboard instrument that emits sounds in both upward and downward directions from speakers solely for upward sound emission and from speakers solely for downward sound emission to realize acoustics similar to that of acoustic piano, and constitutes rear parts of resonance chambers in a speaker box by a common partition plate to prevent the speaker box from becoming complicated in construction. Woofers directed downward are disposed at a lower part of the speaker box, and squawker directed upward are disposed at an upper part of the speaker box. The internal space of the speaker box is partitioned by one horizontal partition plate into an upper space where resonance chambers for the squawkers are defined by vertical partition plates and a lower space where resonance chambers for the woofers are defined by vertical partition plates. Rear parts of the resonance chambers are constituted by the horizontal partition plate.

Owner:YAMAHA CORP

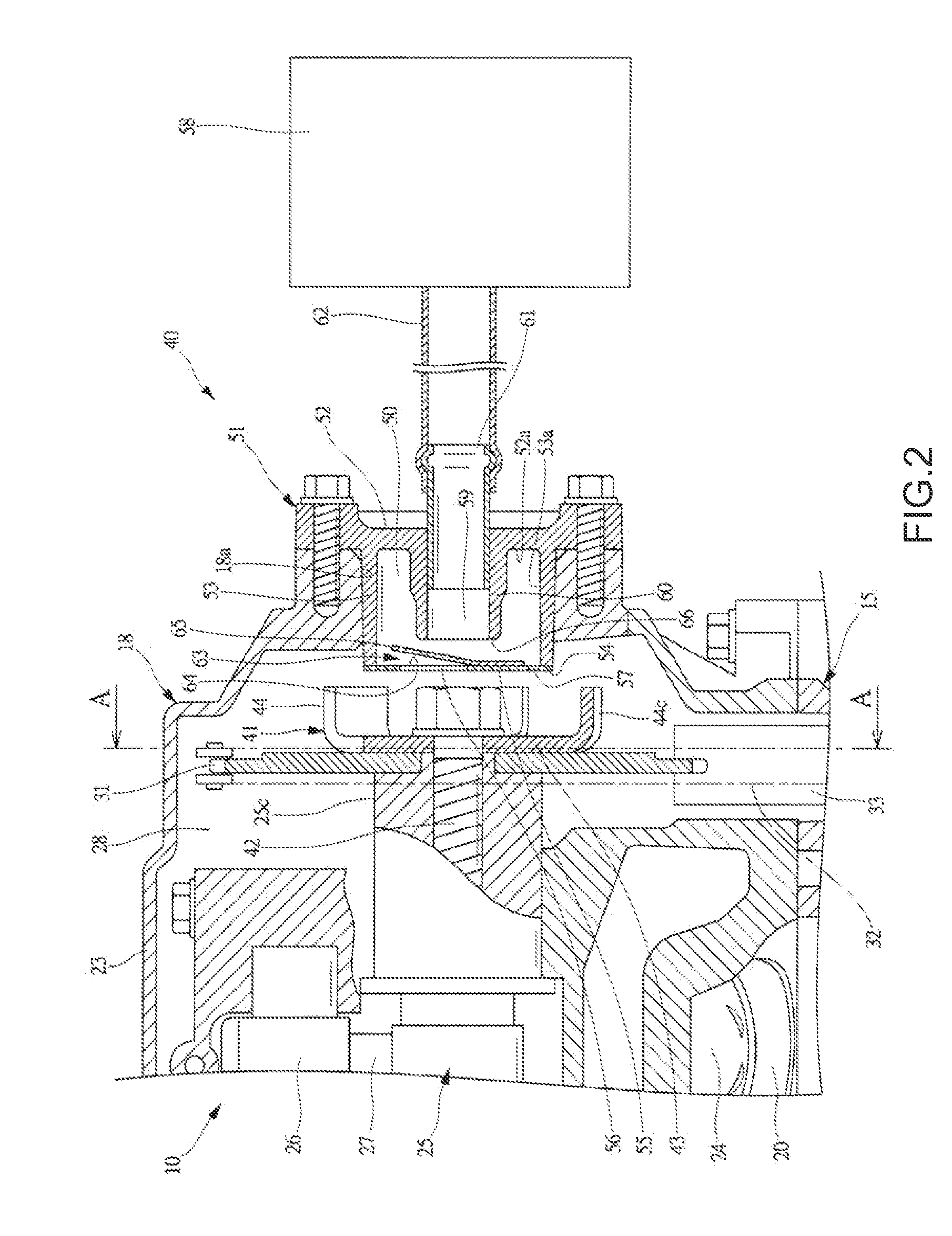

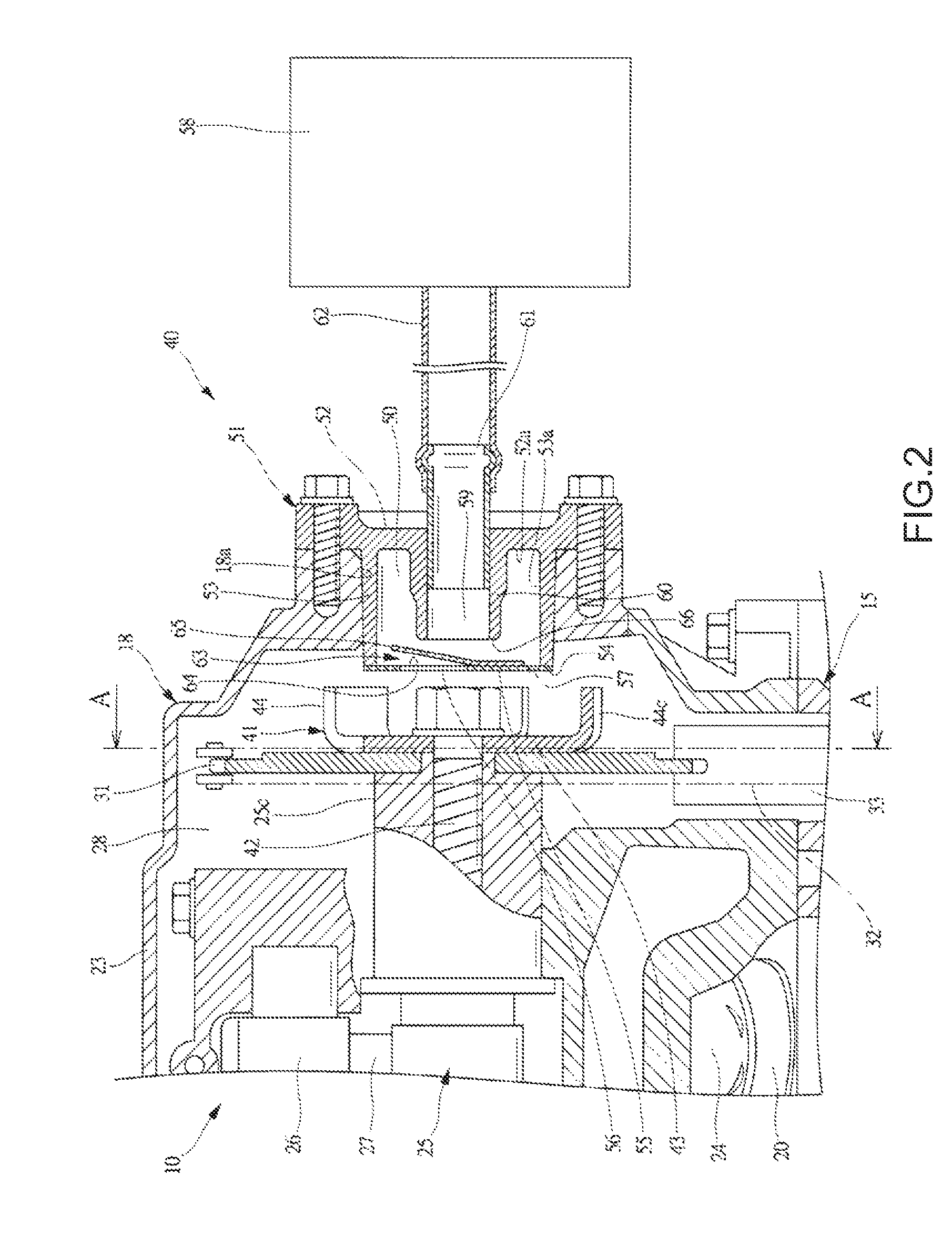

Breather apparatus for engine

InactiveUS20120080015A1Avoid complex constructionSuppression amountCombustion enginesCrankcase ventillationCylinder headEngineering

This breather apparatus has a rotation separator that is fastened to a camshaft, and that rotation separator has a base plate section and a plurality of protruding plates that extend from the base plate section. Moreover, a separator housing is provided in the cylinder head, and comprises an air intake on one end, and an exhaust outlet on the other end. Furthermore, a reed valve that opens and closes by the change in pressure inside a cam chamber is provided in the air intake. Blowby gas that is guided to the cam chamber hits against the protruding plates when passing in the radial direction of the rotation separator, and oil mist is captured by those protruding plates. Continuing, the blowby gas is guided from the cam chamber into the separator housing via the reed valve. When passing through the reed valve, the flow rate of the blowby gas changes, so oil mist is effectively captured by the inner wall surface of the separator housing.

Owner:SUBARU CORP

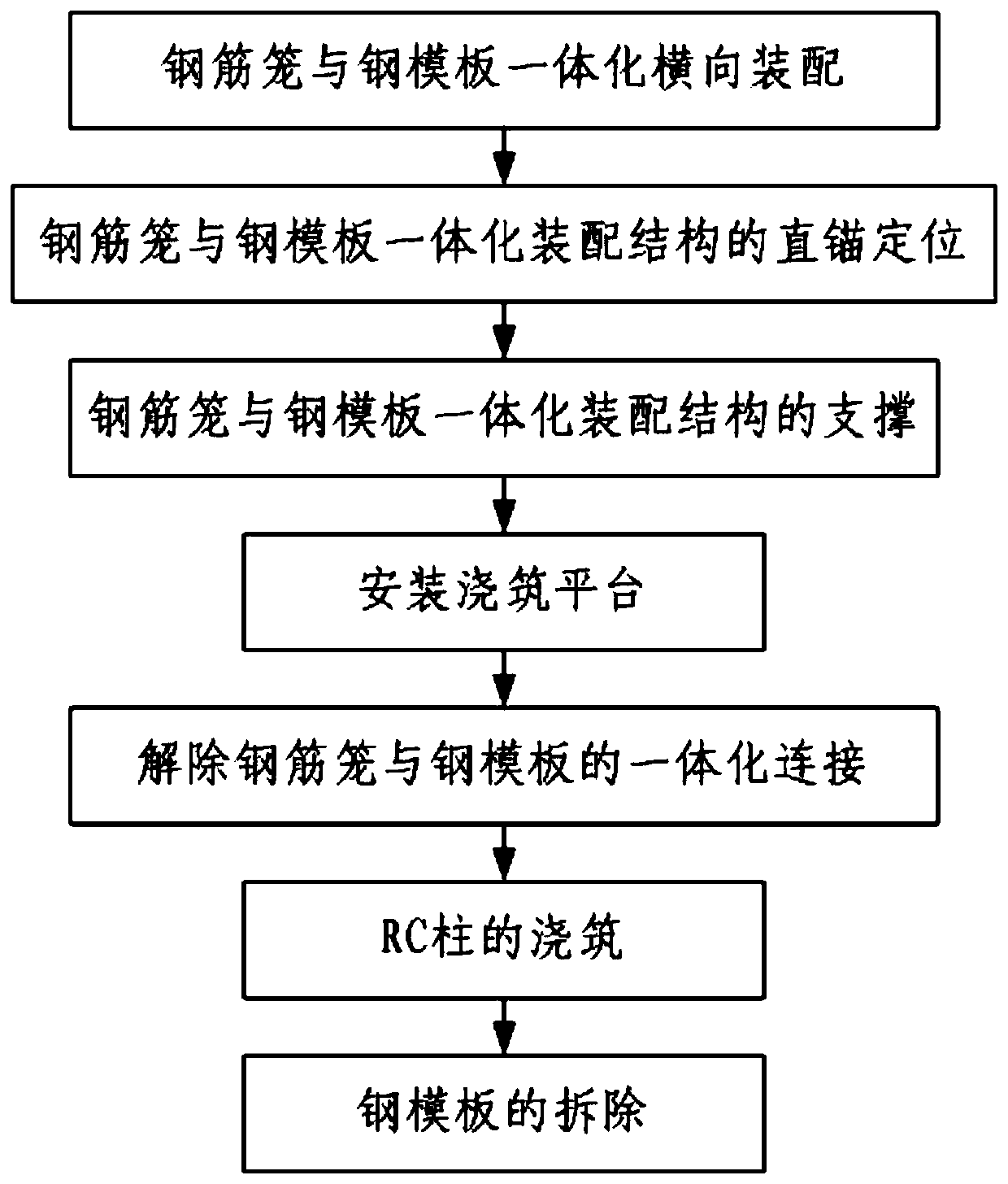

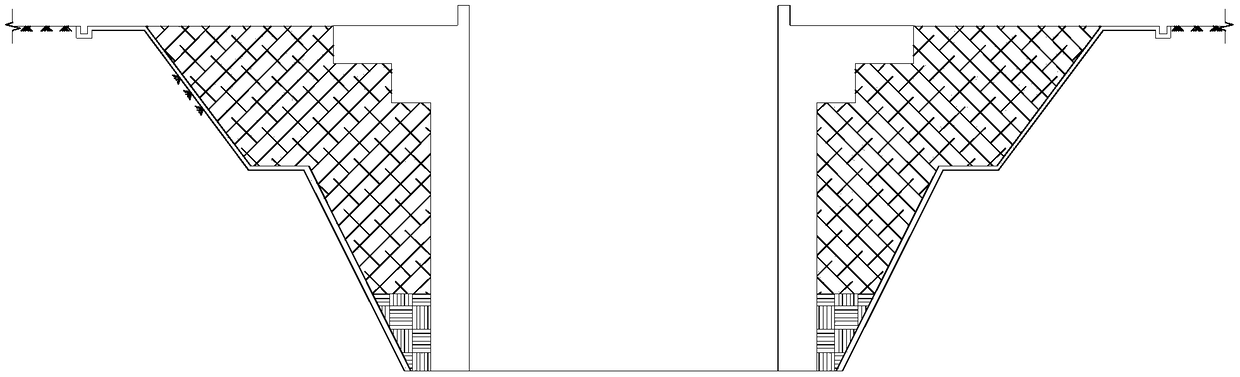

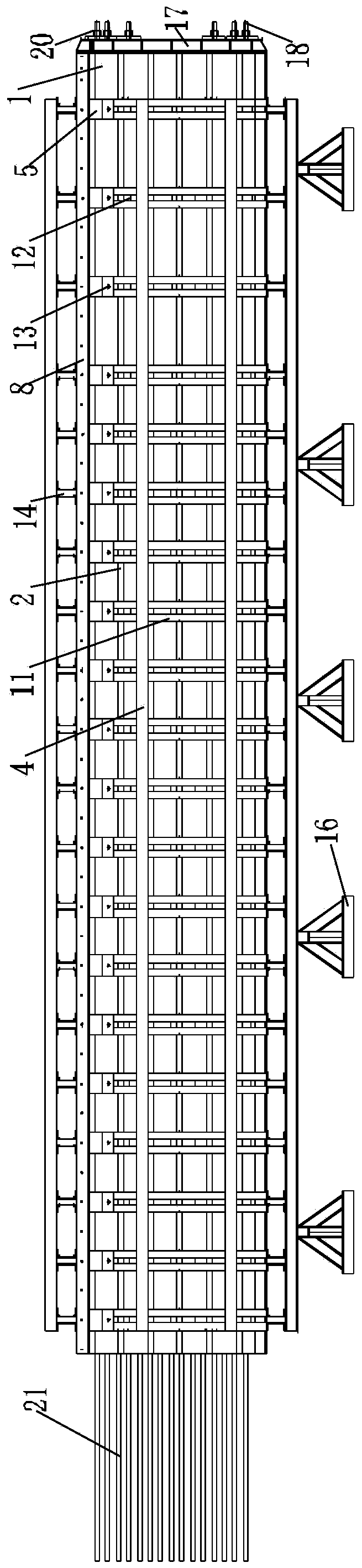

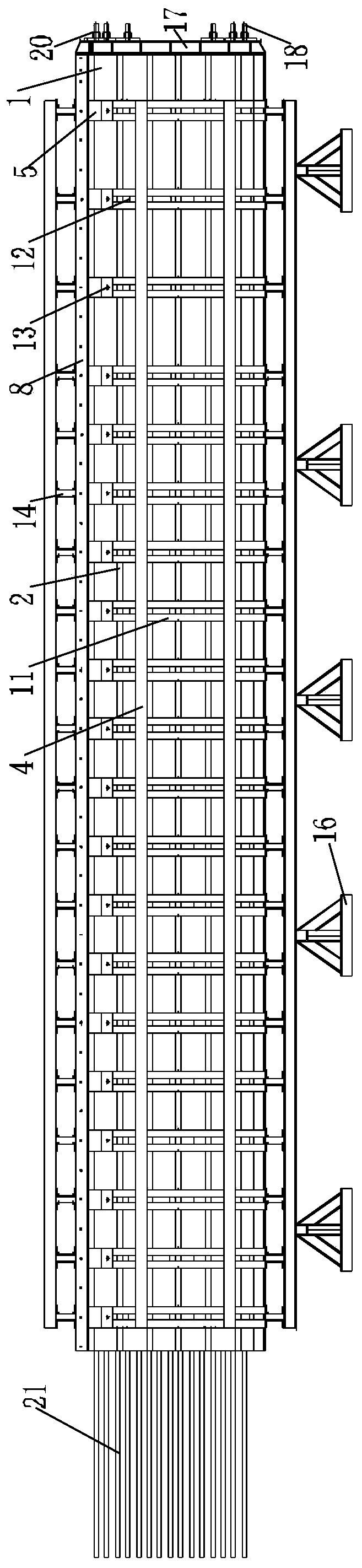

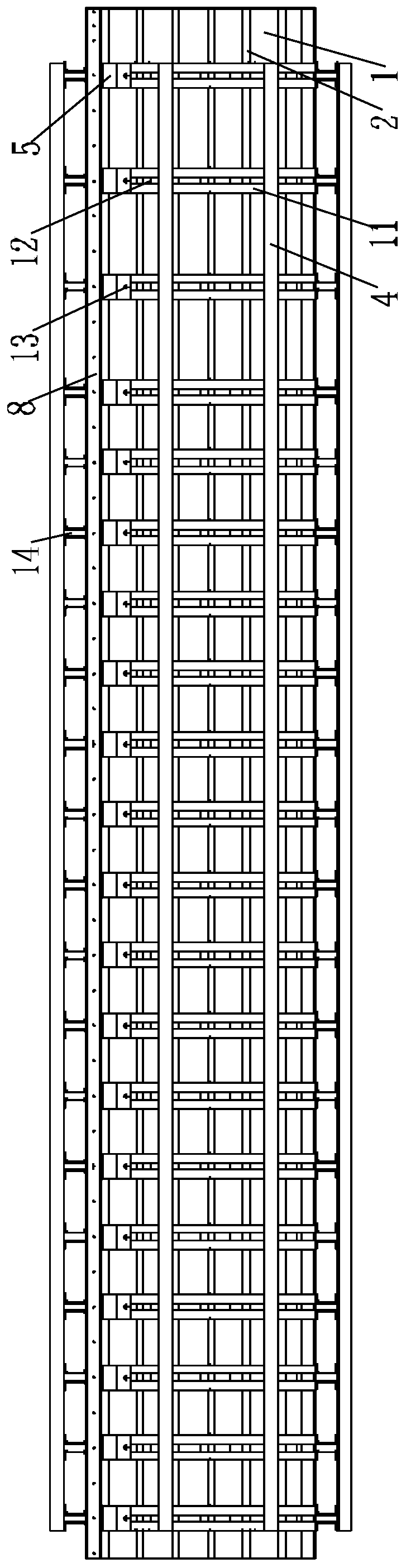

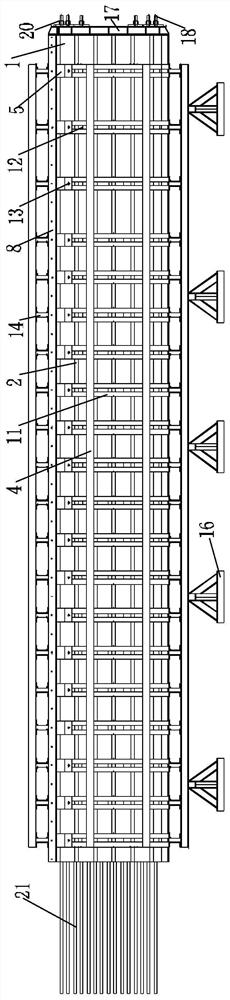

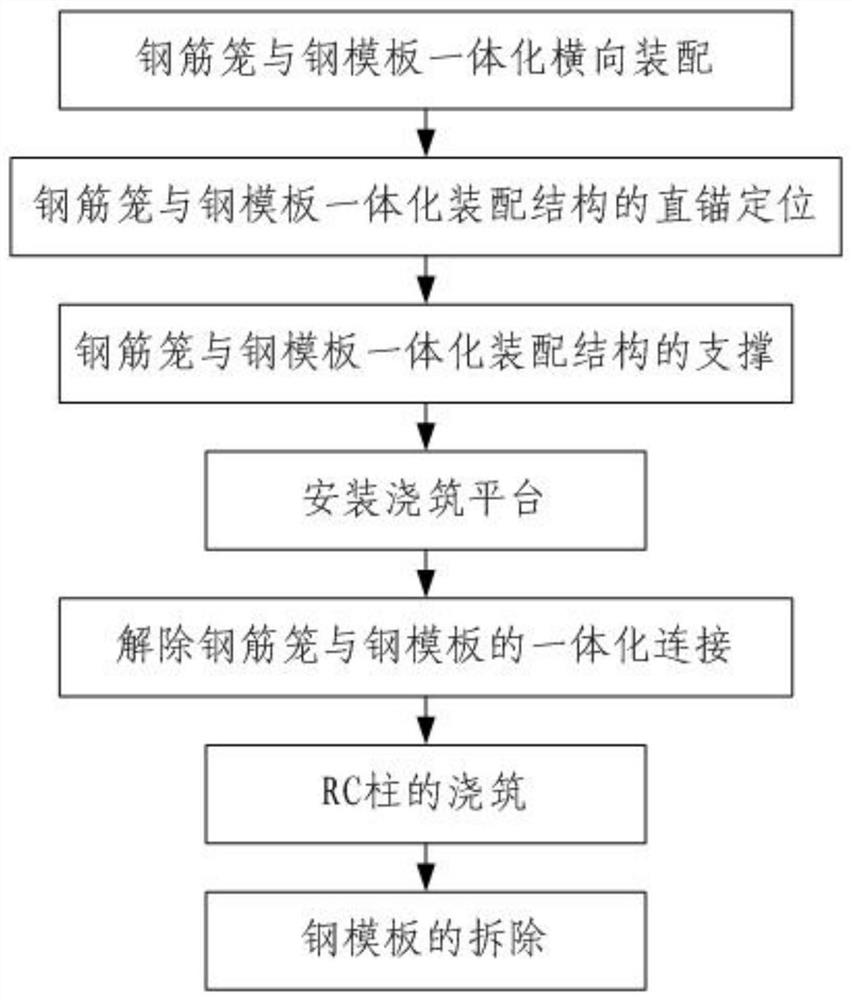

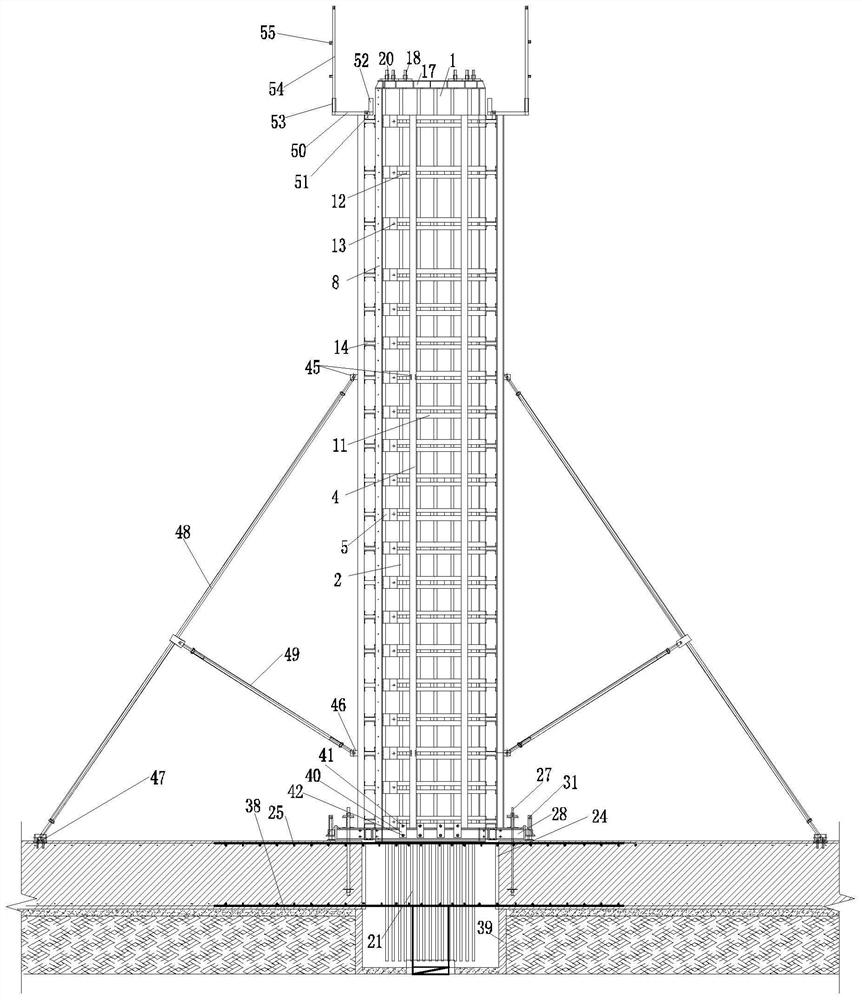

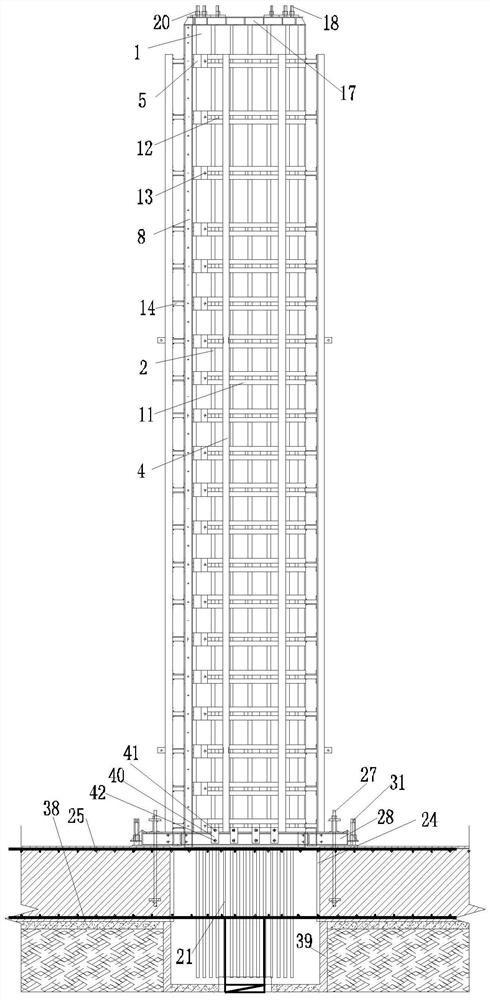

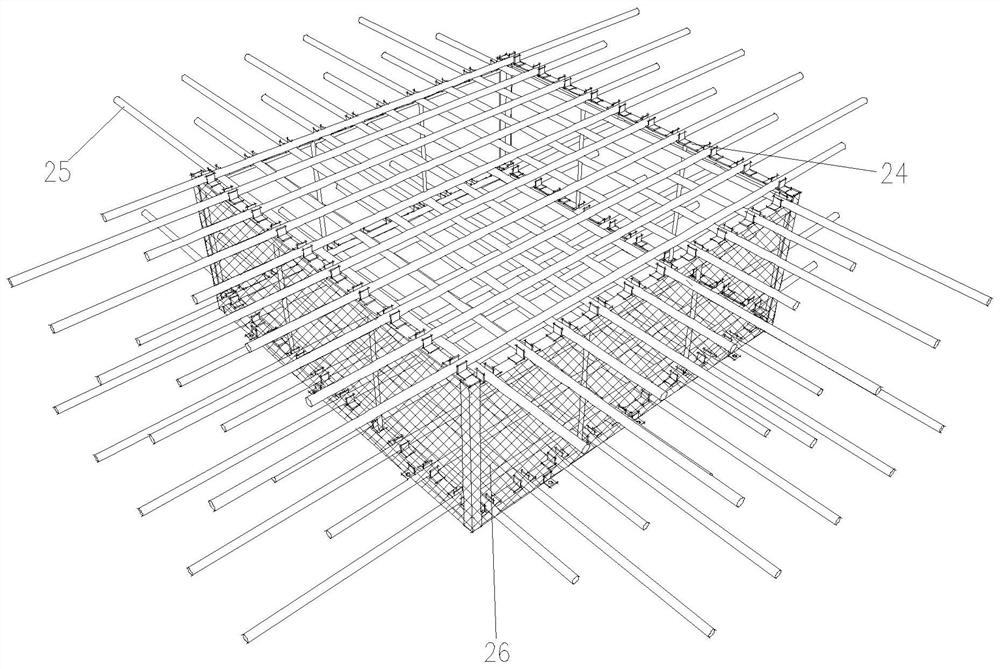

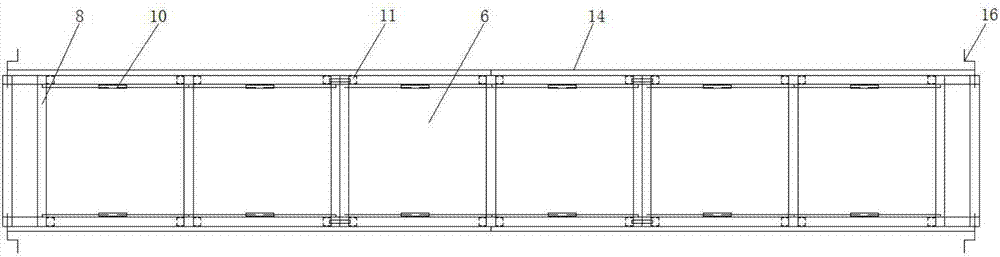

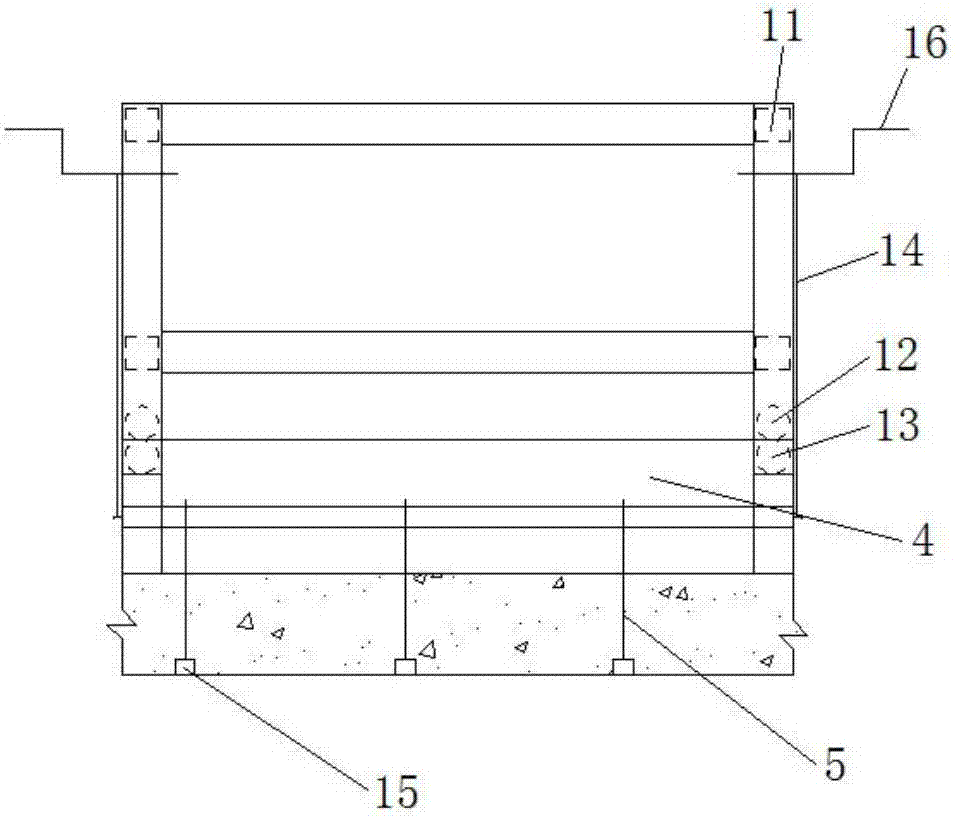

Construction method of semi-fabricated cast-in-place concrete column

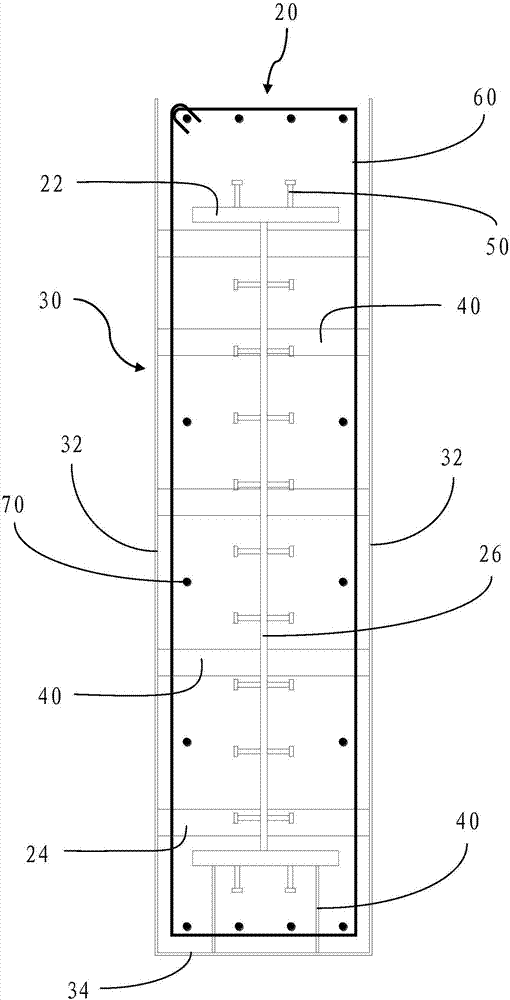

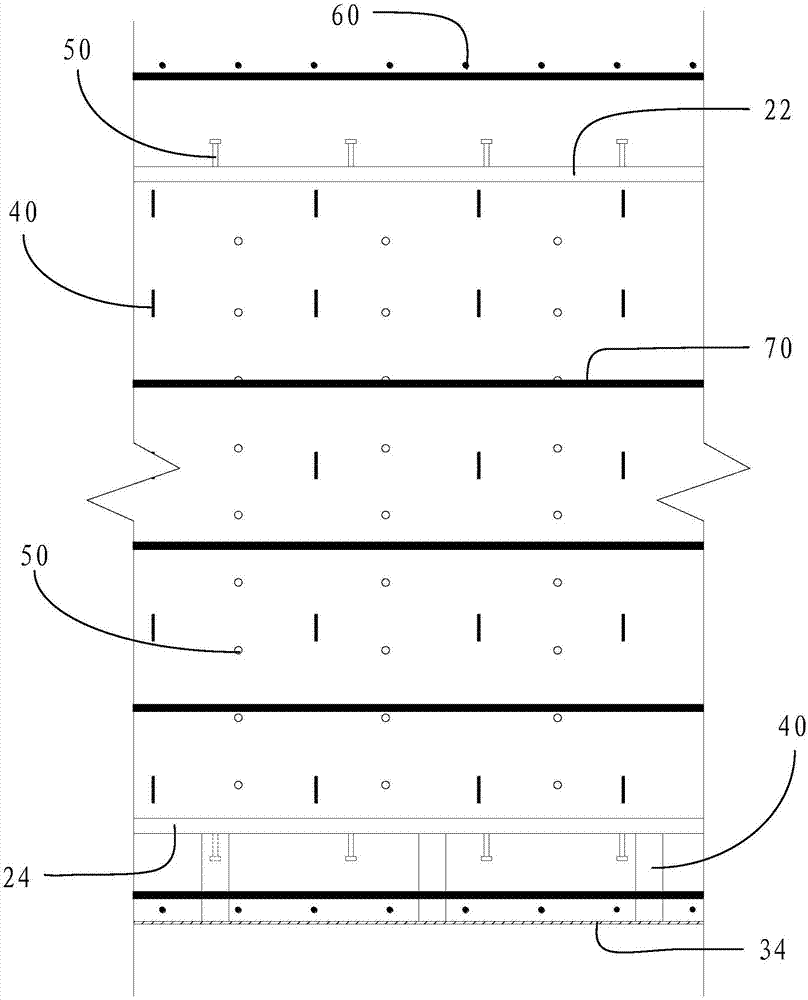

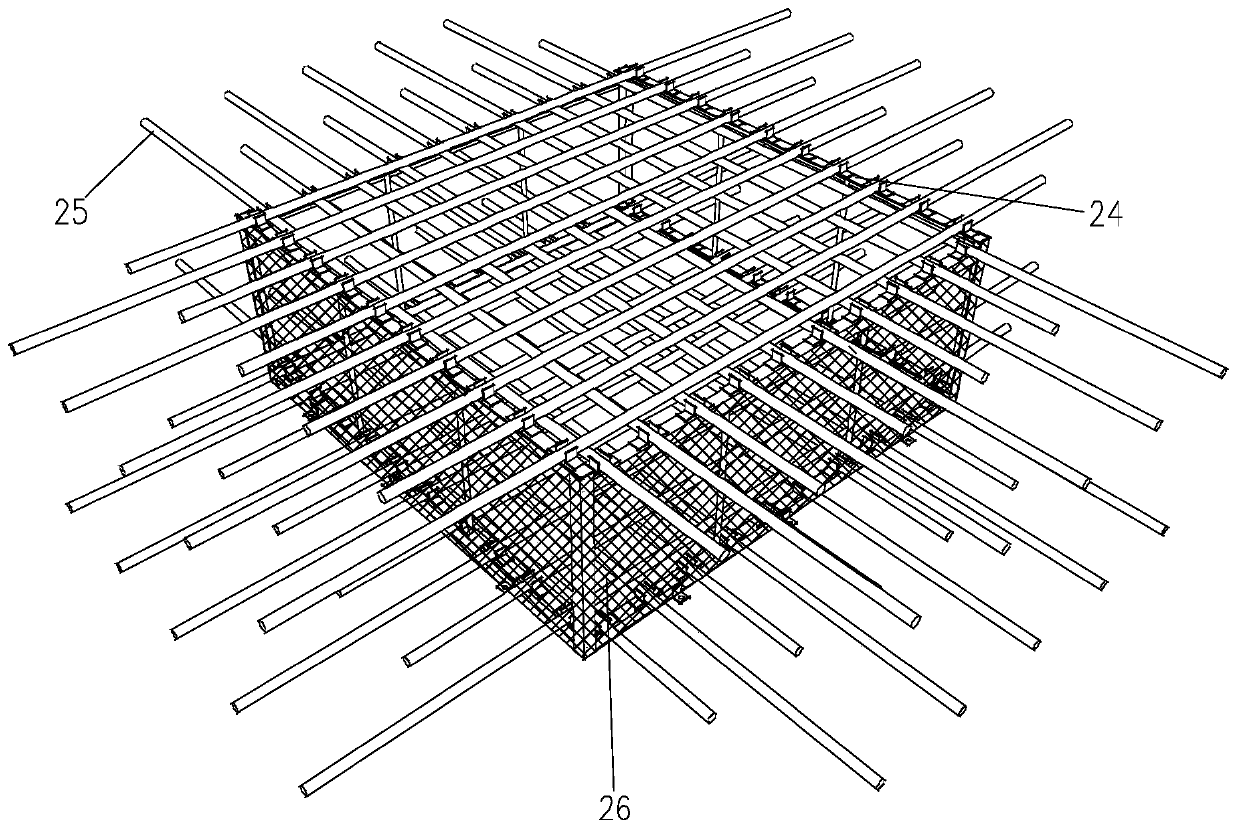

ActiveCN110206228AAvoid complex constructionEasy hoisting and positioningStrutsForms/shuttering/falseworksArchitectural engineeringSlurry

The invention discloses a construction method of a semi-fabricated cast-in-place concrete column. The construction method comprises the steps of 1, integrally and transversely fabricating a reinforcement cage and a steel formwork; 2, carrying out straight-anchorage positioning on a reinforcement cage and steel formwork integrated fabricated structure; 3, supporting the reinforcement cage and steelformwork integrated fabricated structure; 4, mounting a pouring platform; 5, removing integrated connection between the reinforcement cage and the steel formwork; 6, pouring the cast-in-place concrete column; and 7, dismantling the steel formwork. The reinforcement cage and the steel formwork are integrally and transversely fabricated, construction of the reinforcement cage and the steel formworkin a construction site is avoided, and high-altitude operation is avoided; meanwhile, overall hoisting and positioning of the reinforcement cage and the steel formwork are facilitated in the later stage; the pouring platform is arranged at the top end of the reinforcement cage and steel formwork integrated fabricated structure in a sleeving mode, so that the integrated connection between the reinforcement cage and the steel formwork is relieved conveniently, and the concrete pouring work of constructors is facilitated; formwork splicing joints are avoided, no slurry leaks, and the cast-in-place concrete column is poured and formed at a time without construction seams.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

Electronic keyboard instrument

ActiveUS8039725B2Avoid complex constructionImprove distributionElectrophonic musical instrumentsStringed musical instrumentsPianoEngineering

An electronic keyboard instrument that emits sounds in both upward and downward directions from speakers solely for upward sound emission and from speakers solely for downward sound emission to realize acoustics similar to that of acoustic piano, and constitutes rear parts of resonance chambers in a speaker box by a common partition plate to prevent the speaker box from becoming complicated in construction. Woofers directed downward are disposed at a lower part of the speaker box, and squawker directed upward are disposed at an upper part of the speaker box. The internal space of the speaker box is partitioned by one horizontal partition plate into an upper space where resonance chambers for the squawkers are defined by vertical partition plates and a lower space where resonance chambers for the woofers are defined by vertical partition plates. Rear parts of the resonance chambers are constituted by the horizontal partition plate.

Owner:YAMAHA CORP

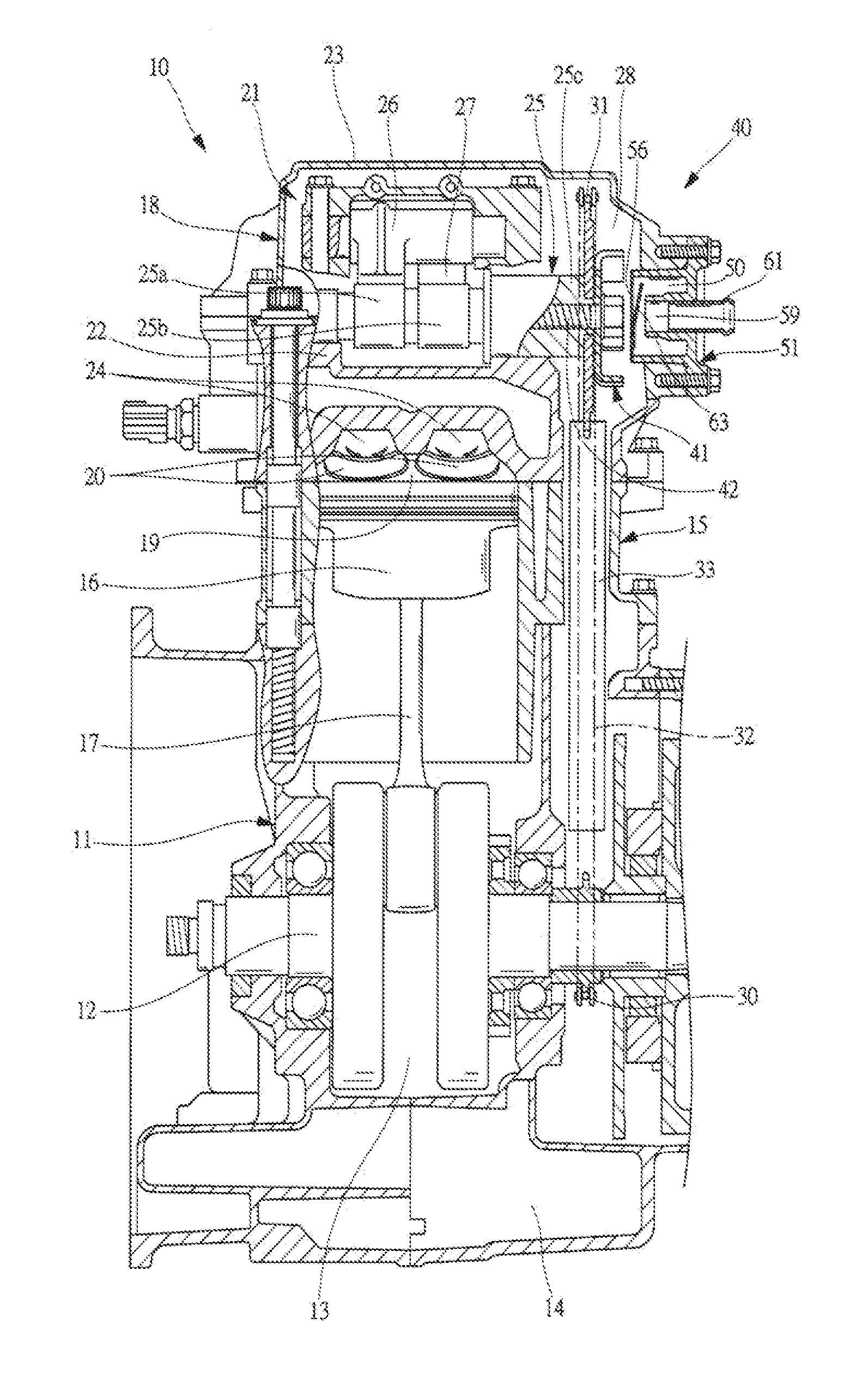

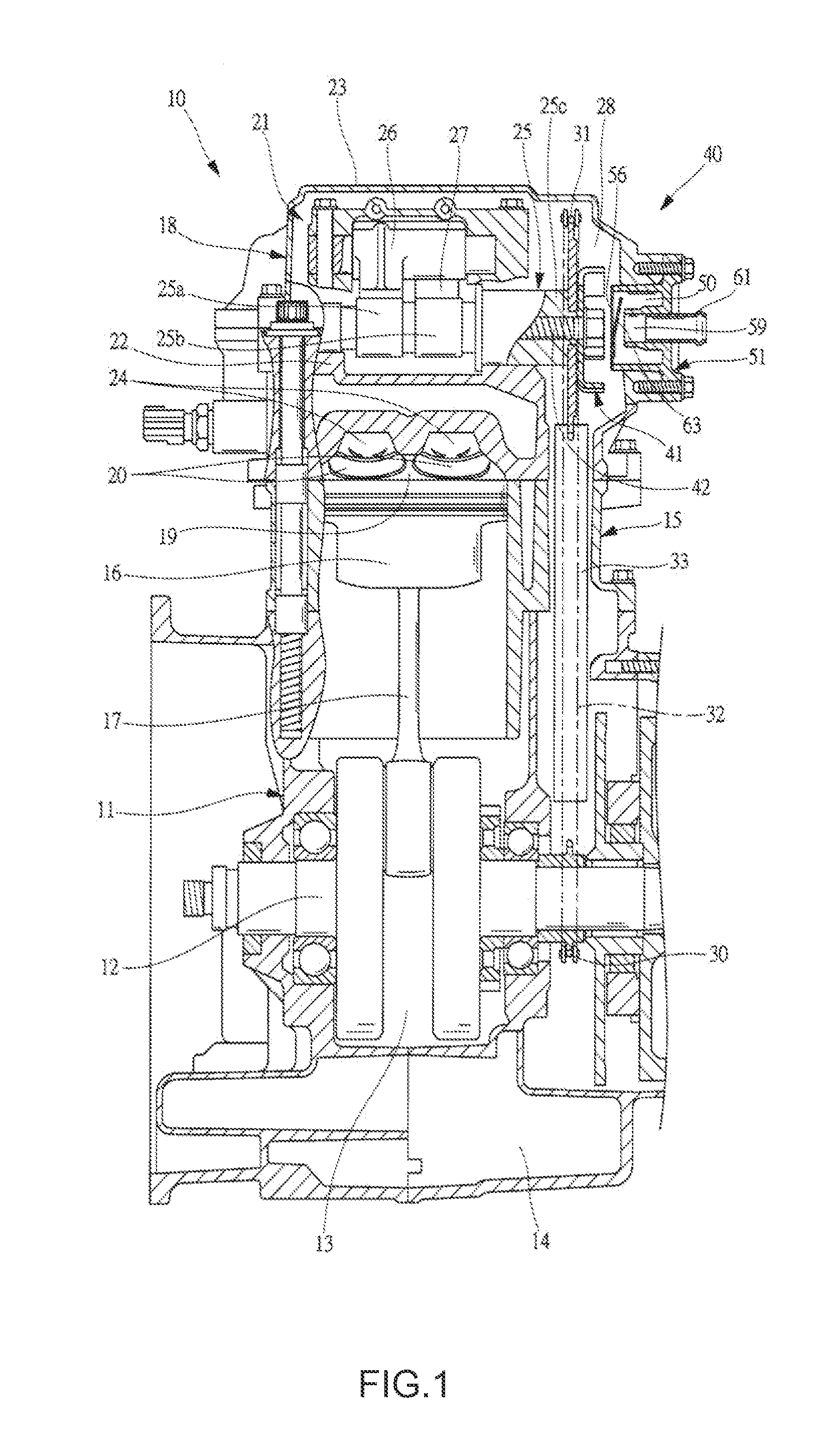

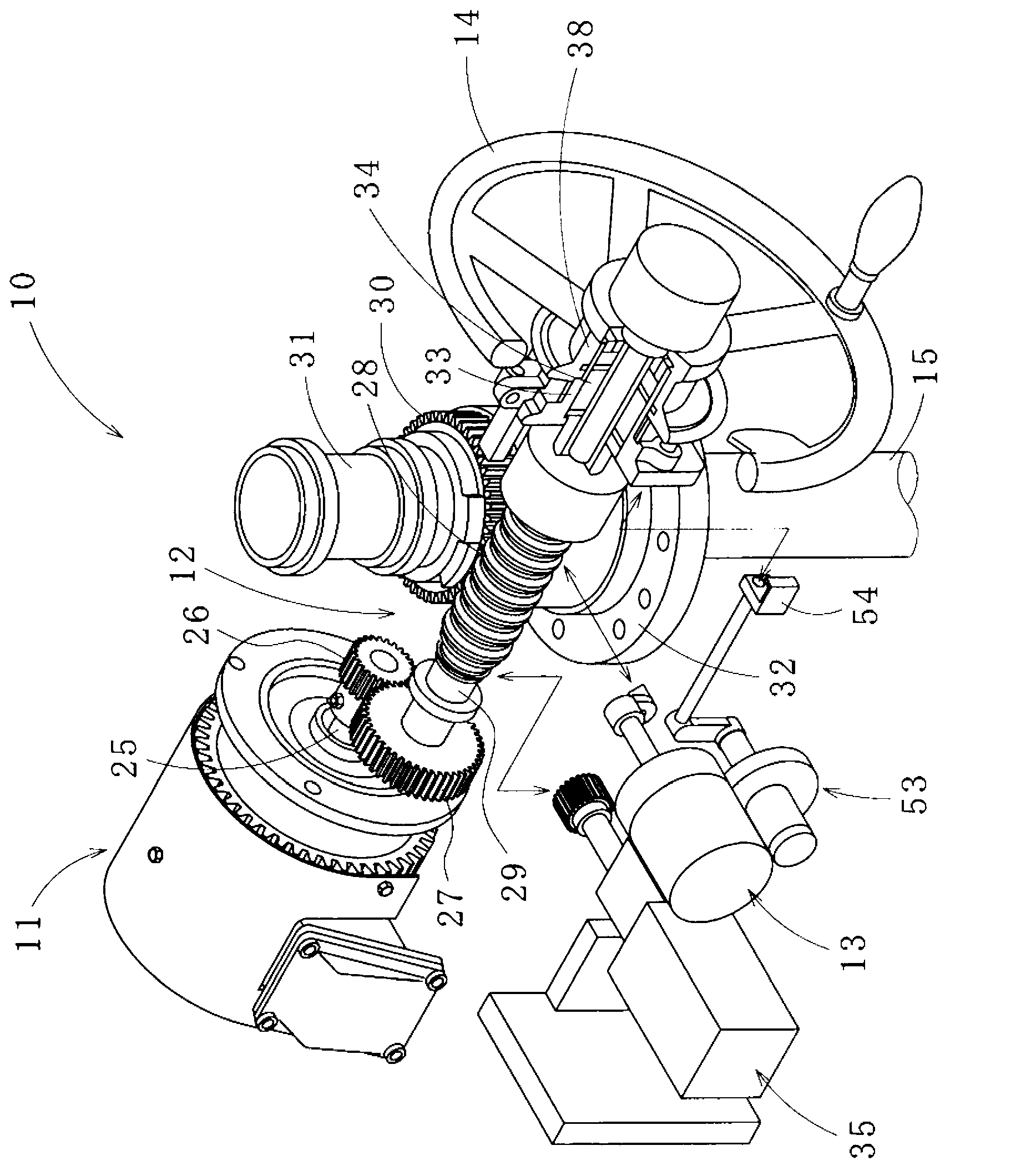

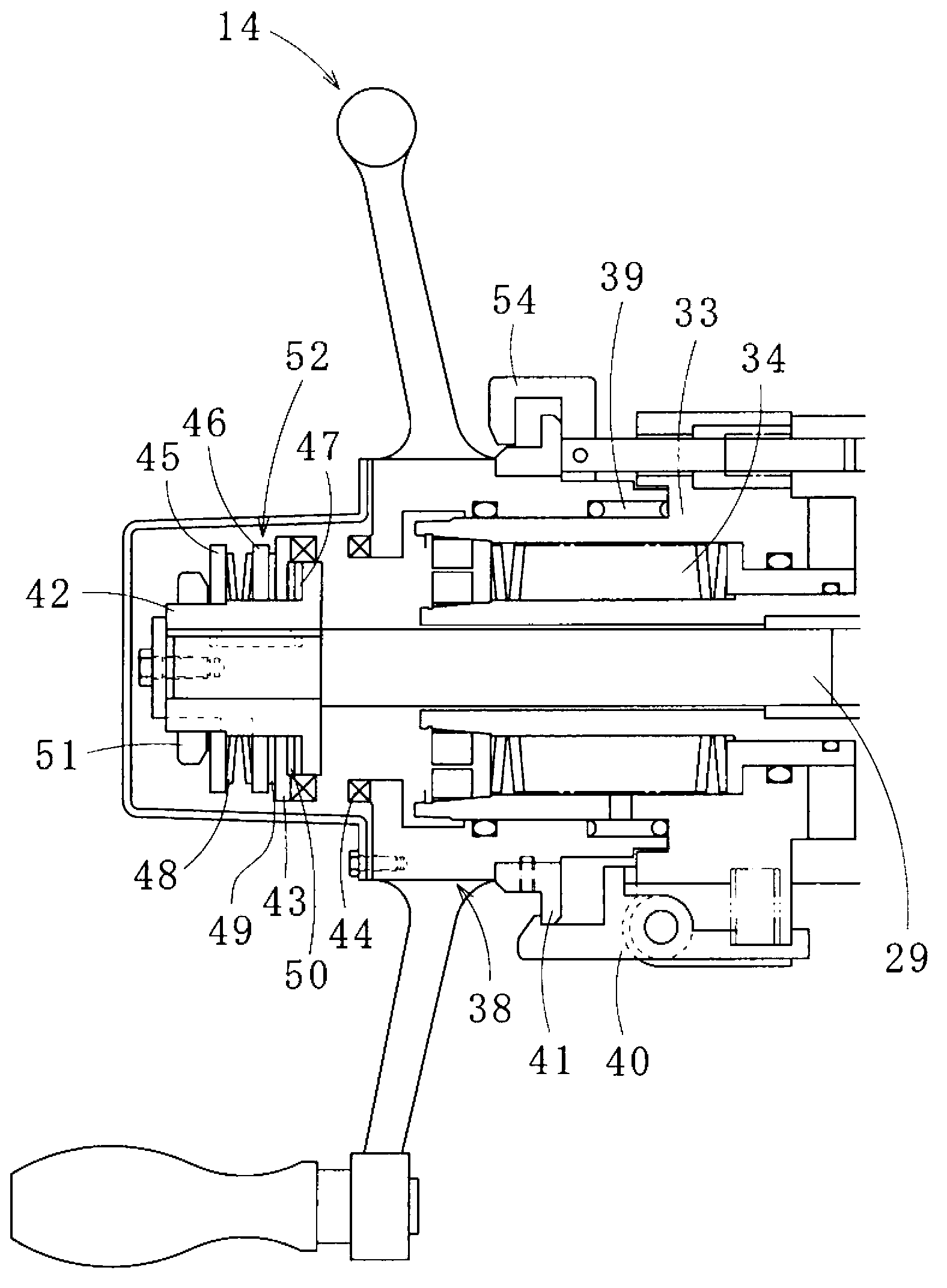

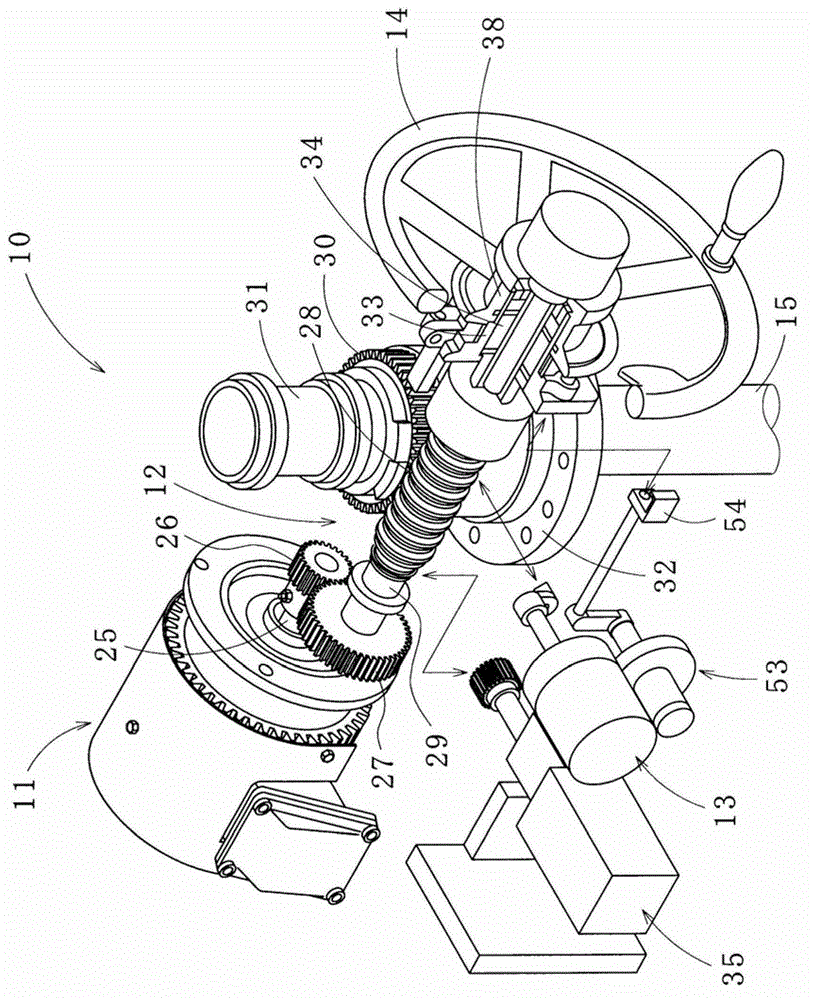

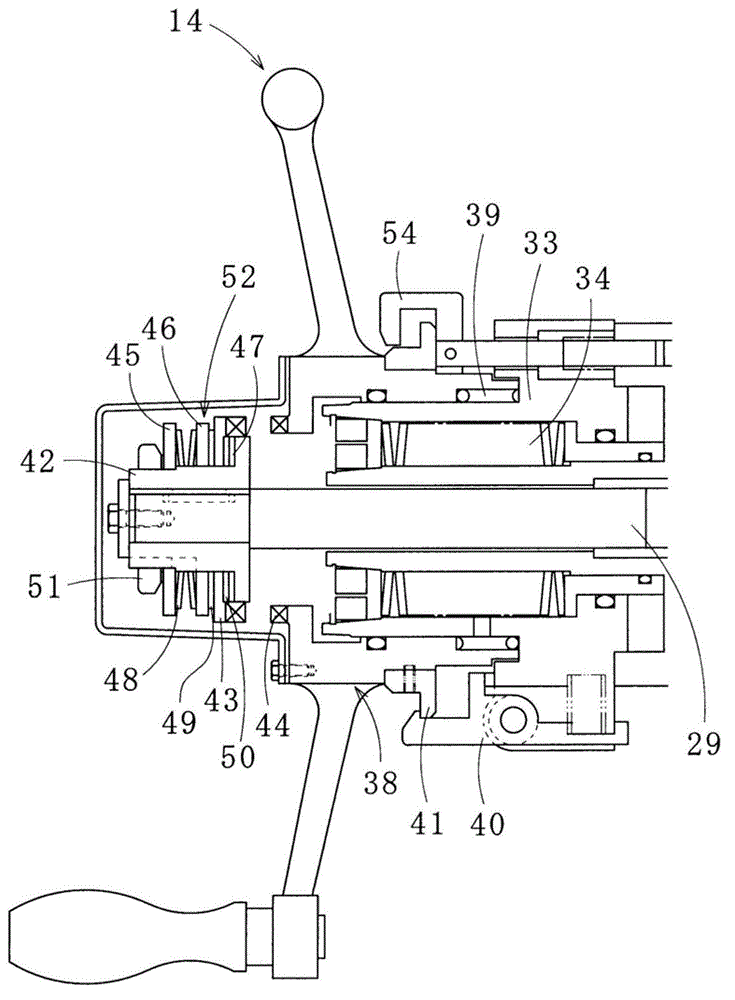

Valve controller, electric gate valve and electric valve

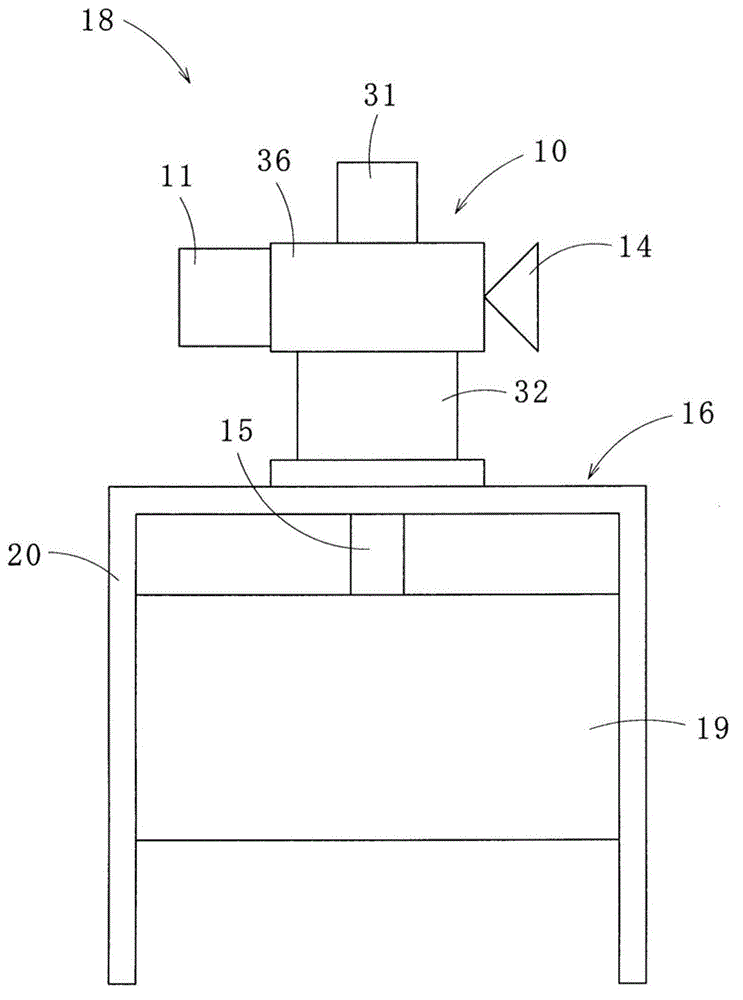

ActiveCN103256420ALimit loadAvoid damageOperating means/releasing devices for valvesWhole bodyElectric machine

Provided are a valve controller, an electric gate valve and an electric valve. The valve controller (10) comprises a motor (11); a power transmission unit (12) that transmits driving power of the motor to an external machine; a torque limiter (13) that makes the motor stop when the power transmission unit generates certain load during running of the motor; and a hand-operated handle (14) that applies power onto the external machine through the power transmission unit. The hand-operated handle has a rotatable body that is connected with the hand-operated handle to be a whole body to rotate; a torque drive part that is connected with the power transmission unit; and a friction generation part that enables friction to be generated between the rotatable body and the torque drive part. When torque applied by the hand-operated handle onto the rotatable body exceeds the friction between the rotatable body and the torque drive part, the torque drive part is separated from the power transmission unit and the rotatable body. Therefore, power of transmission to the external machine is limited via operation of the handle when load with the prescribed amount is generated.

Owner:WEST ELECTRIC CO LTD

TBM hoisting and translation method for deep well confined space

The invention discloses a TBM hoisting and translation method for a deep well confined space. The TBM hoisting and translation method for the deep well confined space comprises the steps that S1, deepwell hoisting is carried out; S2, the size and weight of TBM main parts are selected; S3, hoisting personnel are allocated; S4, hoisting machines and tools are prepared; S5, hoisting equipment is selected; S6, a construction site is prepared; S7, the bearing capacity of a foundation is calculated; S8, the load rate is calculated; S9, the crane selection performance is calculated; and S10, hoisting testing is carried out. The construction method solves the problems of deep well hoisting, large weight translation and slag discharge in a confined space in the field of urban rail transit, complexconstruction is avoided, the costs are saved, the construction experience of similar projects is accumulated for enterprises, the technical reserve of the enterprises is enhanced, guidance and reference for urban rail transit construction under similar conditions can be provided, and good promotion, application value and social influence are achieved.

Owner:NO 1 ENG CO LTD OF CHINA RAILWAY 22ND CONSTR BUREAU +1

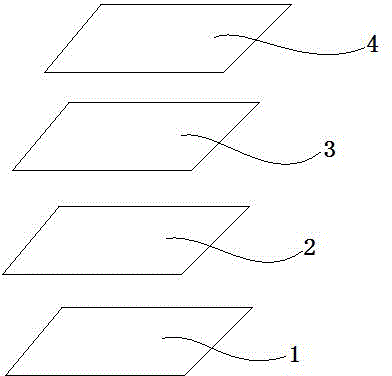

Structure of rapidly molded concrete cloth and laminating method

InactiveCN104818722AHigh tensile strengthImprove bending resistanceRoadwaysSynthetic resin layered productsGeomembraneHot melt

The invention provides a structure of rapidly molded concrete cloth and a laminating method. The structure comprises a concrete base cloth layer and a non-woven cloth layer; a prefabricated cement concrete dry-mixed powder layer is arranged between the concrete base cloth layer and the non-woven cloth layer; the peripheries of the non-woven cloth layer and the concrete base cloth layer are laminated, wound and bonded together in a needling or sewing and knitting manner; a PVC / HDPE waterproof geomembrane layer is laminated on the outer surface of the non-woven cloth layer in a hot melting rolling manner. The concrete cloth is simple and convenient to use, quick in solidification and molding, environmental friendly, high in application flexibility, high in material strength, long in service life, waterproof and flame retardant.

Owner:焦剑锋

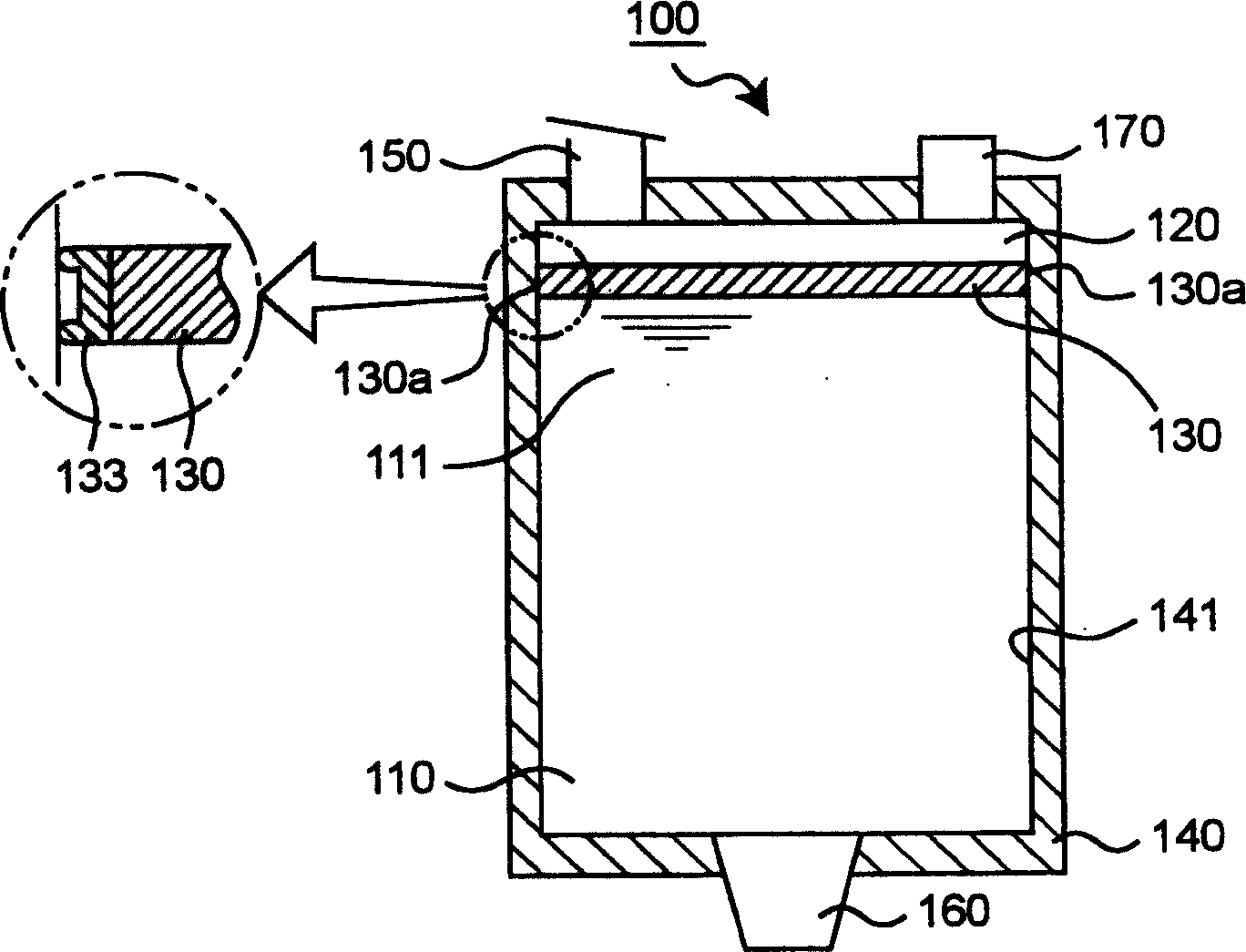

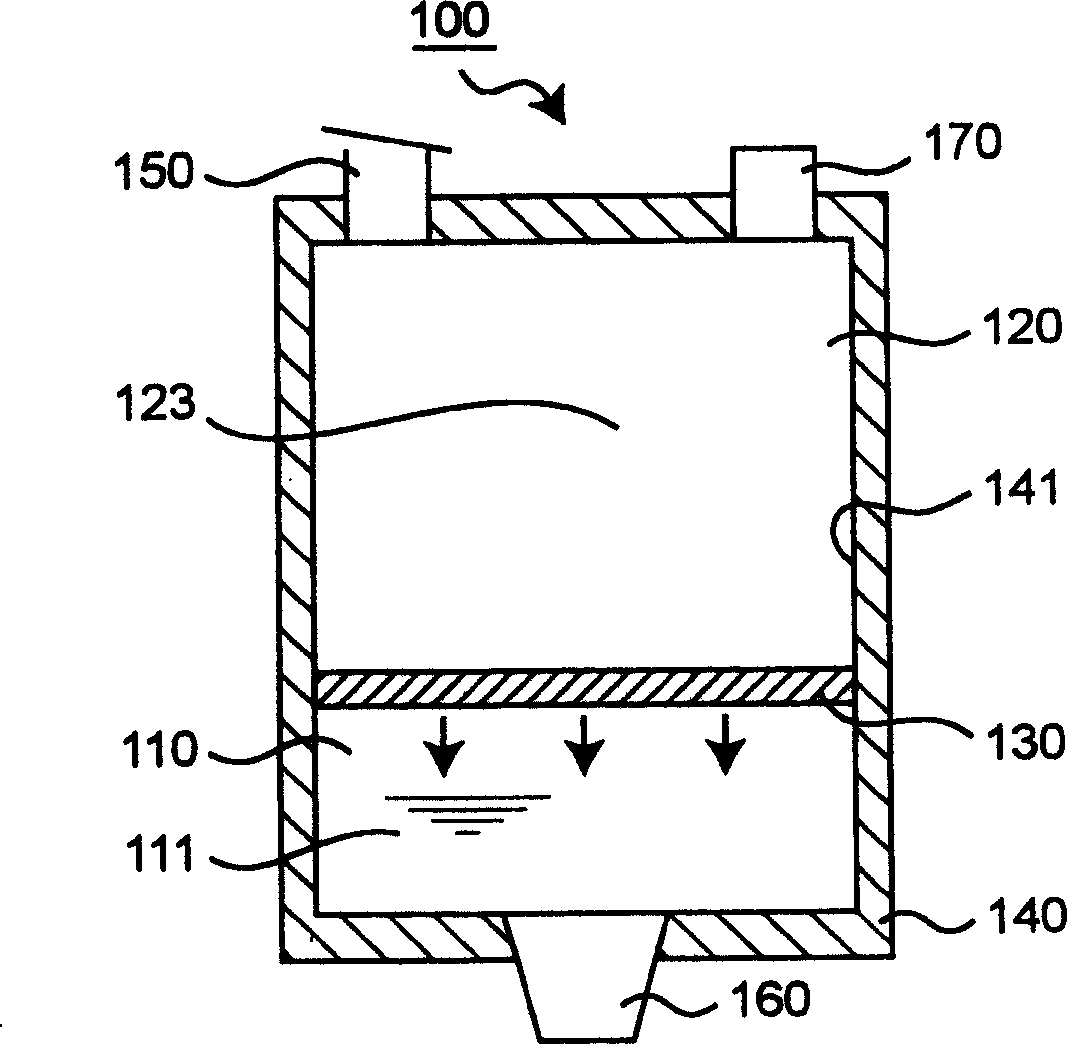

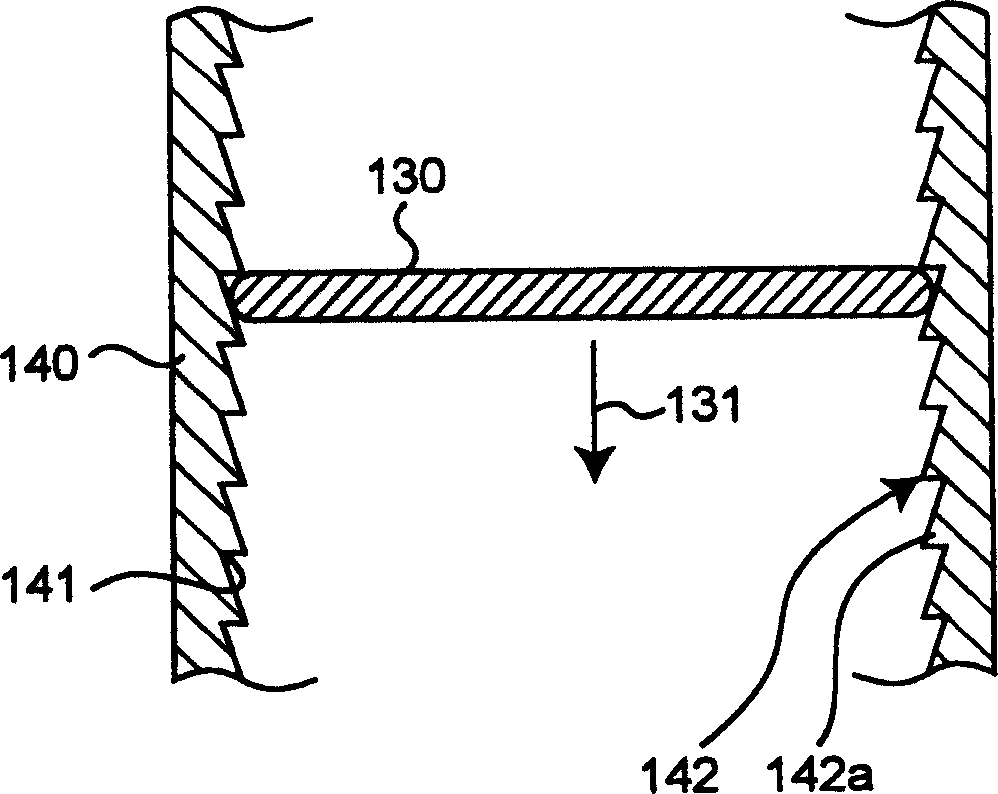

Fuel tank for fuel-cell and fuel cell system

InactiveCN1574436AStable supplySimple compositionReactant parameters controlLarge containersFuel cellsFuel tank

Provided is a fuel tank for a fuel cell and fuel cell system capable of supplying fuel in any direction of installment and processing exhausted substance. The fuel tank is constructed so as to press the fuel (111) to be supplied to the fuel cell main body (200) by pressing a separation plate (130) moving through the inside of a casing (140) by the exhausted substance (123) exhausted from the fuel cell main body. By the above, the fuel can be stably supplied to the fuel cell main body whether the fuel tank for the fuel cell (100) and the fuel cell system (30) are installed in any direction. In addition, since the exhausted substance is utilized for pressing the separation plate, the exhausted substance can be processed.

Owner:PANASONIC CORP

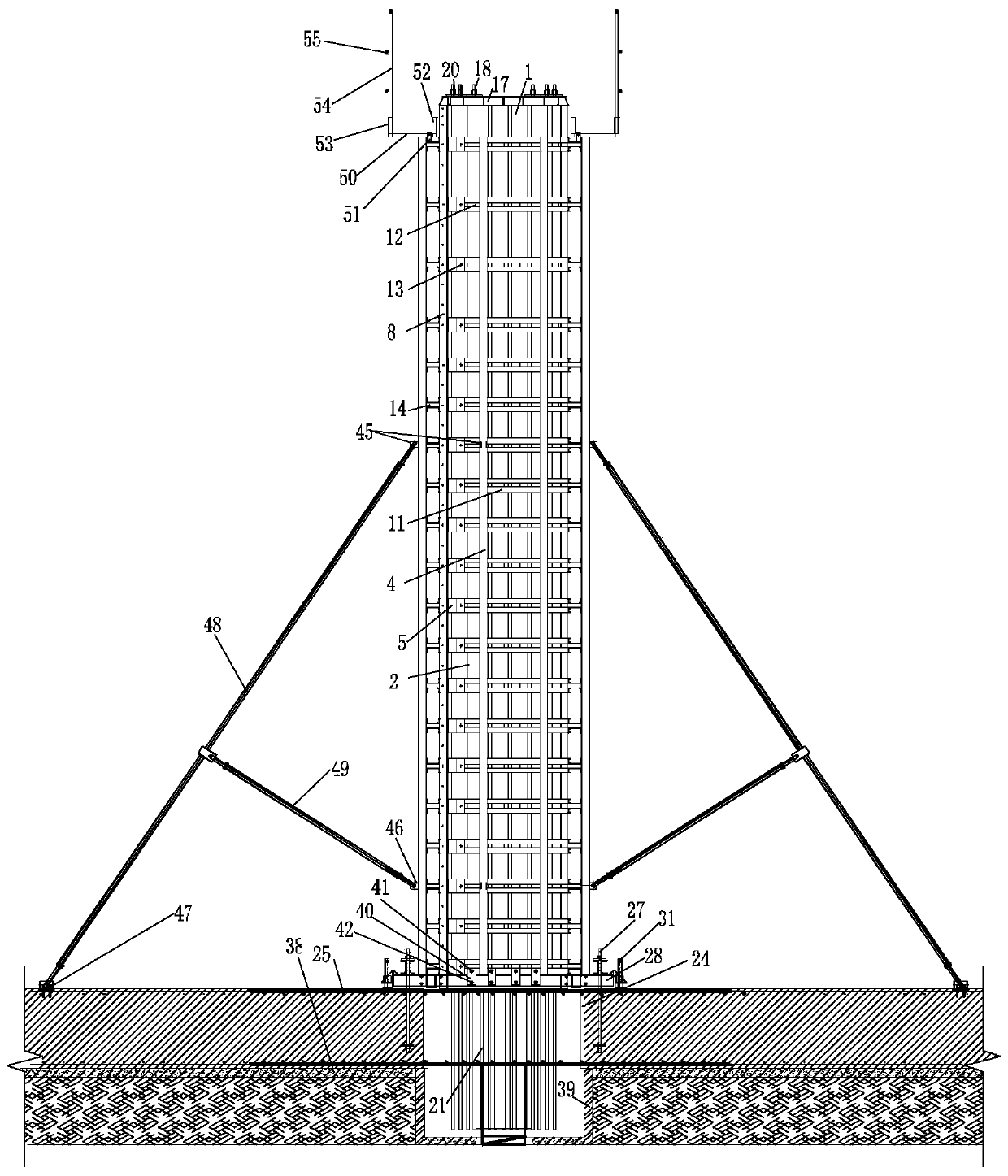

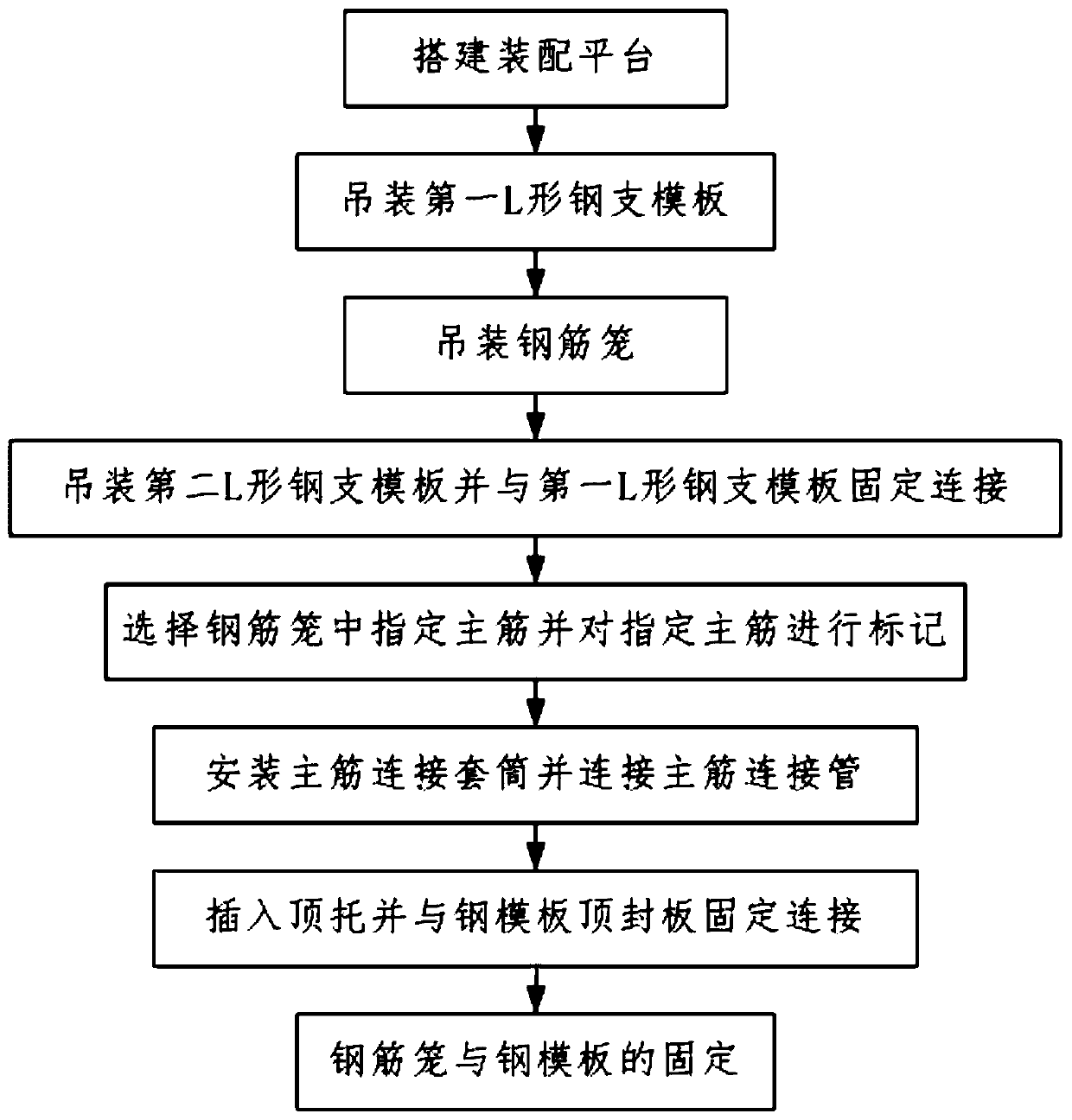

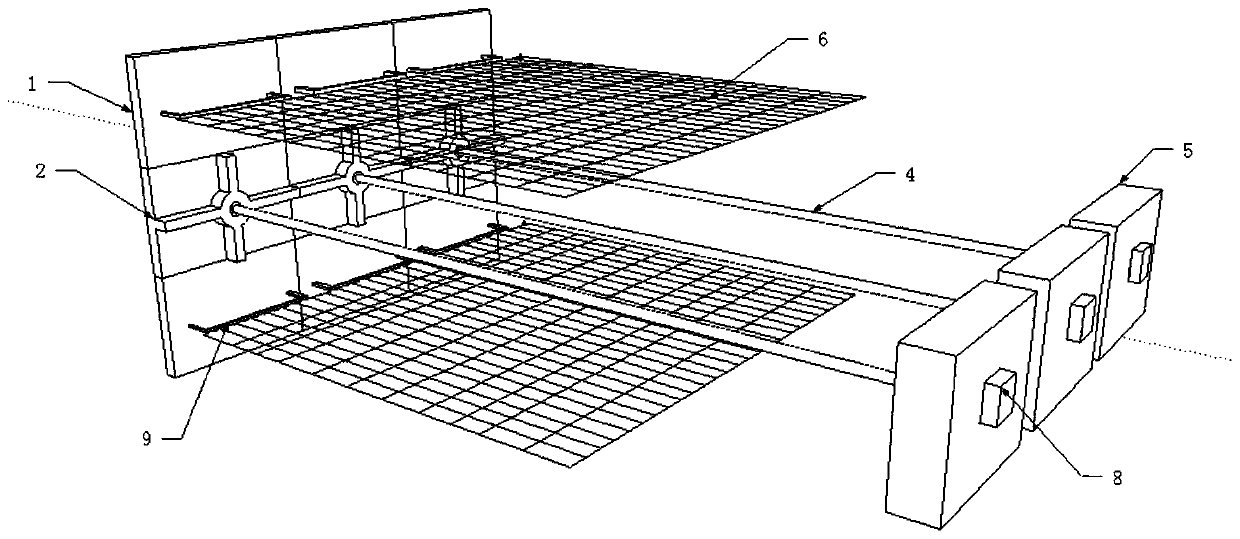

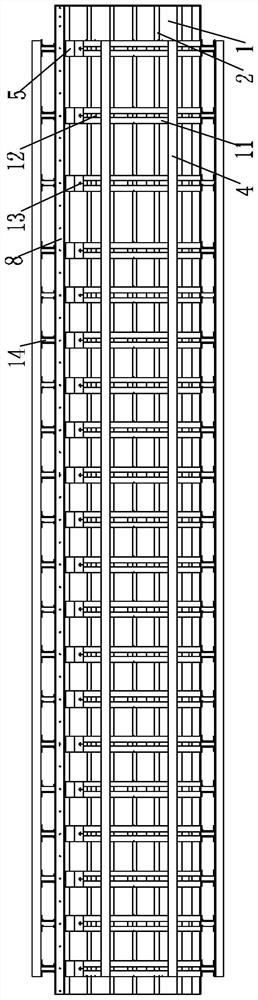

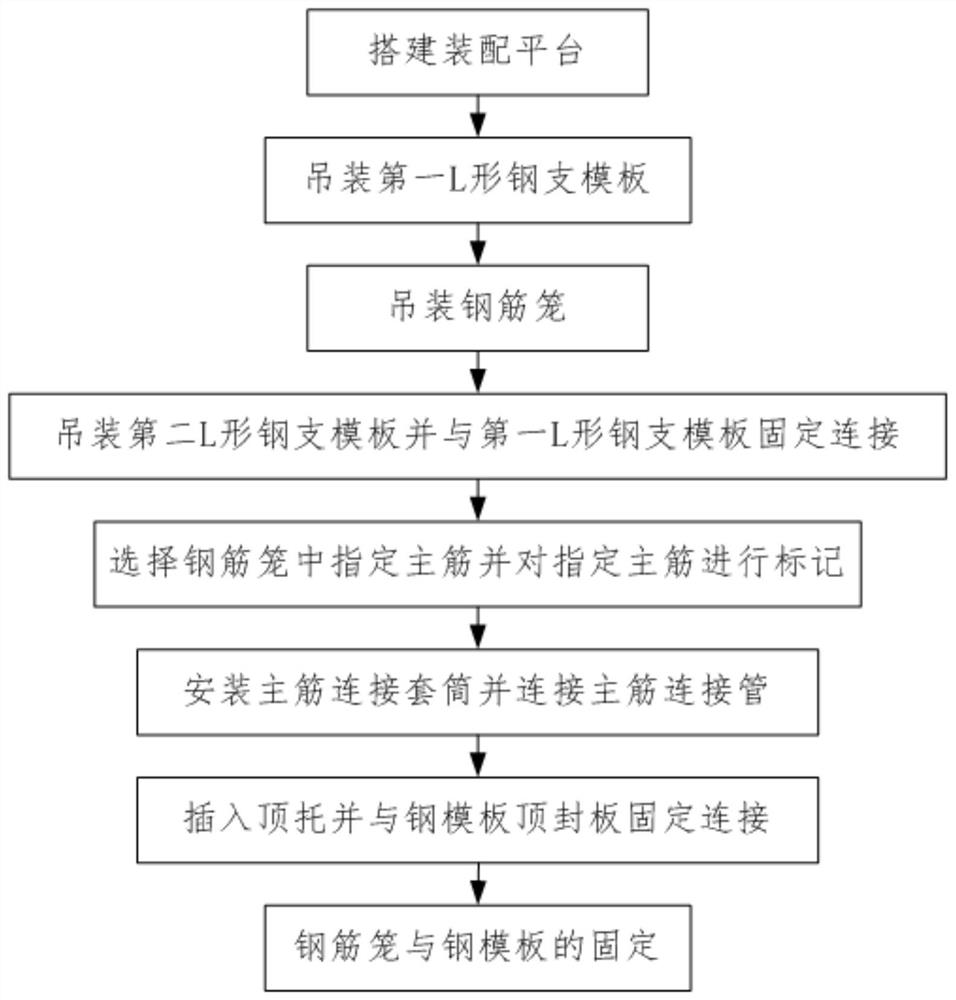

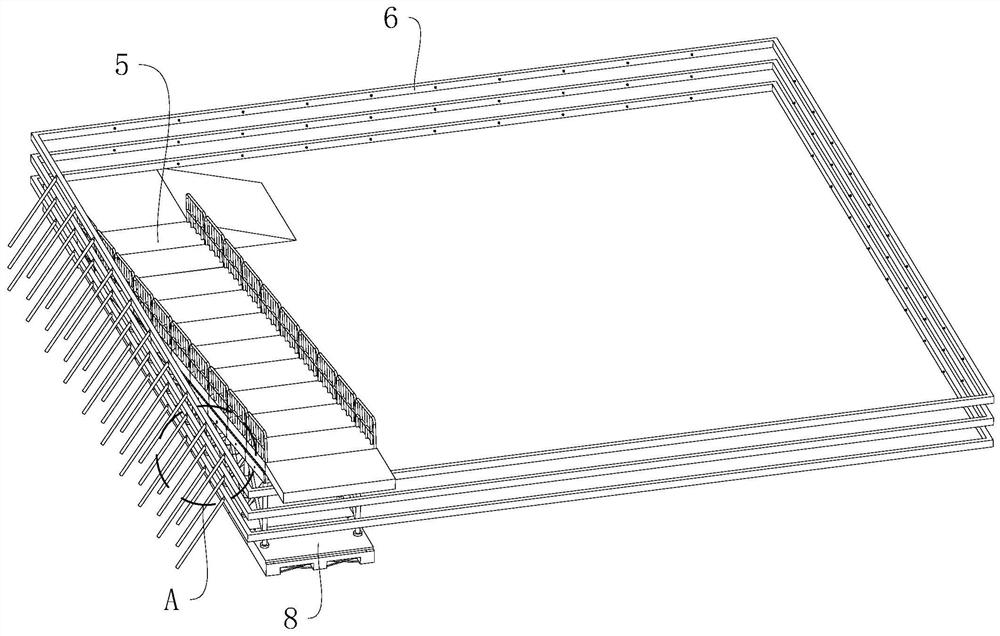

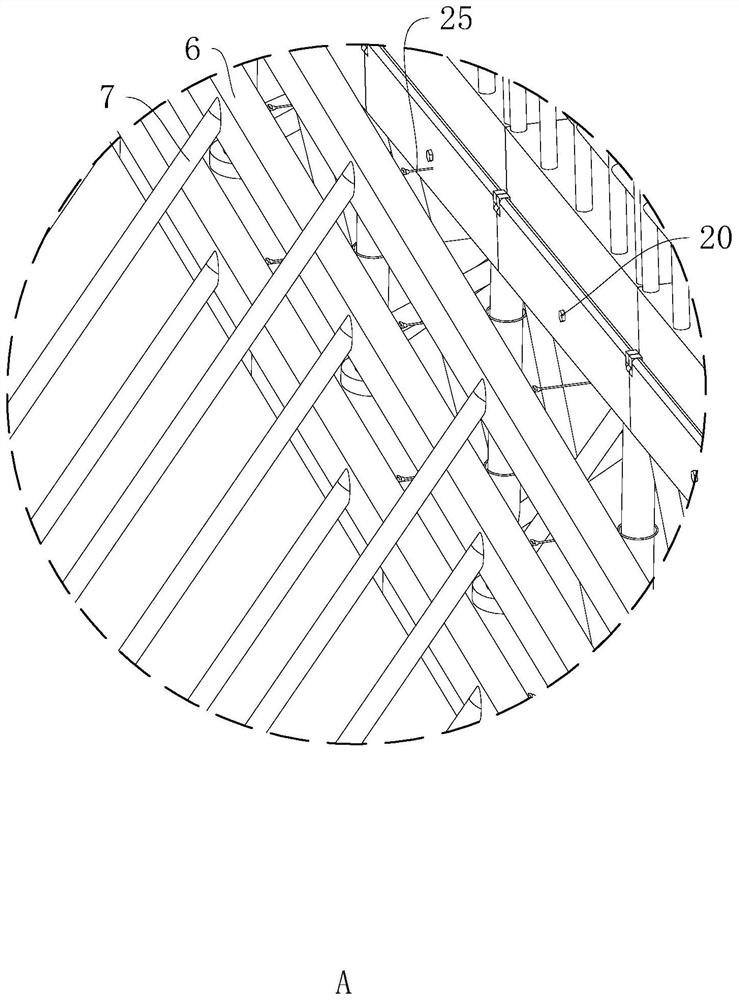

Reinforcement cage and steel formwork integrated transverse assembly method

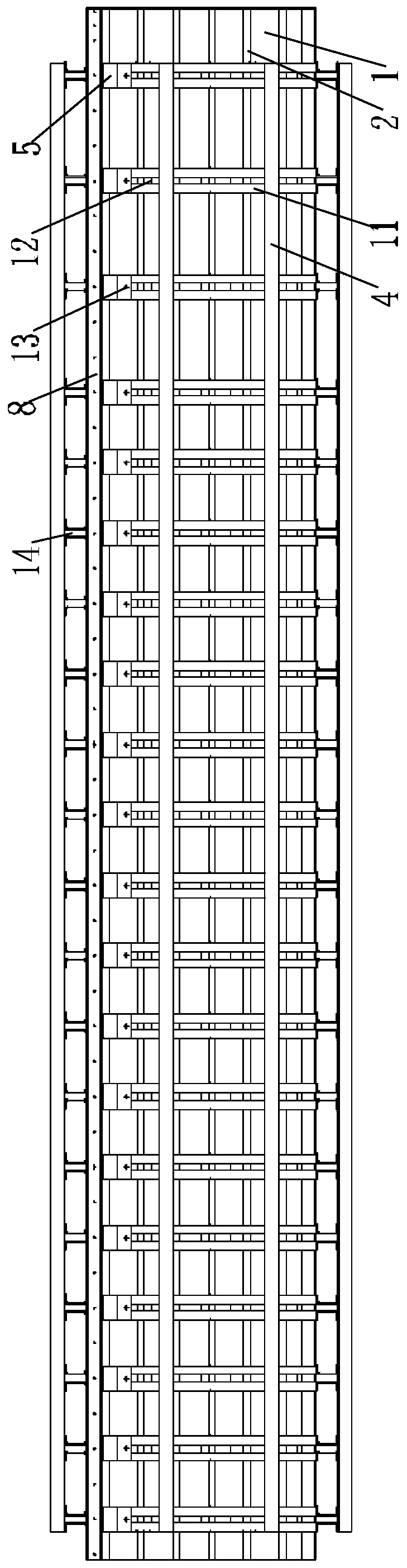

ActiveCN110206306AHigh input costFlexible useForms/shuttering/falseworksBuilding reinforcementsRebarBuilding construction

The invention discloses a reinforcement cage and steel formwork integrated transverse assembly method. The reinforcement cage and steel formwork integrated transverse assembly method comprises the steps: 1, an assembly platform is set up; 2, a first L-shaped steel formwork is hoisted; 3, a reinforcement cage is hoisted; 4, a second L-shaped steel formwork is hoisted and fixedly connected with thefirst L-shaped steel formwork; 5, designated steel bars in the reinforcement cage are selected and marked; 6, a main bar connecting sleeve is mounted and connected with main bar connecting pipes; 7, ajack is inserted and fixedly connected with a steel formwork top sealing plate; and 8, the reinforcement cage and a steel formwork are fixed. Through splicing of the first L-shaped steel formwork andthe second L-shaped steel formwork, the reinforcement cage is placed in the steel formwork and fixed, the subsequent main bar connecting pipes are mounted advantageously by marking the designated main bars, through cooperation of the jack, the main bar connecting pipes, the main bar connecting sleeve and a main bar fixing sleeve, the reinforcement cage and the steel formwork are fixed into a whole, later overall hoisting of the reinforcement cage and the steel formwork is convenient, and thus the construction process is simplified.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

Fabricated foam concrete outer wall insulation board, structure thereof and mounting method of fabricated foam concrete outer wall insulation board

ActiveCN107476451AImprove stabilityAvoid complex constructionHeat proofingFoam concreteBuilding construction

The invention discloses a fabricated foam concrete outer wall insulation board, the structure thereof and a mounting method of the fabricated foam concrete outer wall insulation board. The fabricated foam concrete outer wall insulation board comprises a fabricated foam concrete outer wall insulation board body, an external hanging piece, a connecting piece and a wall-hanging piece. When the fabricated foam concrete outer wall insulation board body is mounted, a connecting rod of the connecting piece is inserted into a casing pipe of the external hanging piece, a long hole formed in a bottom plate of the connecting piece and a mounting hole in the wall-hanging piece are connected through a bolt, a wall-hanging hole in the wall-hanging piece is connected with a wall, and finally the space between the fabricated foam concrete outer wall insulation board body and the wall is filled with foam concrete to form a filled layer. A veneer layer and a foam concrete layer of the fabricated foam concrete outer wall insulation board are reinforced mechanically, the fabricated foam concrete outer wall insulation board can be mounted on the building outer wall through the mounting pieces in a fabricated mode, influence of wall matrix is avoided, construction is easy and convenient, the construction period is short, cost is low, and safety is good.

Owner:ANYANG INST OF TECH +1

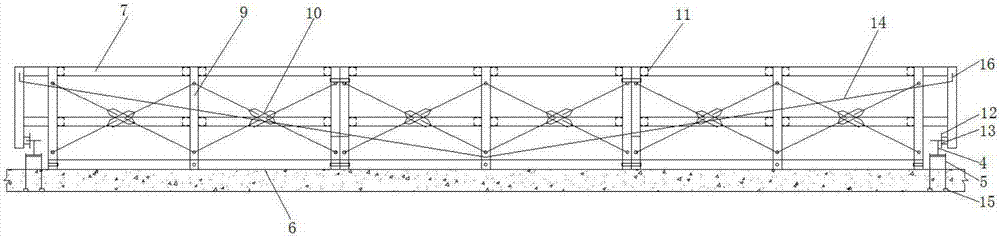

Large-span stiff beam screw-free structure and construction method thereof

PendingCN107083821AImprove bending abilityImprove stabilityLoad-supporting elementsForms/shuttering/falseworksFloor slabLong span

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

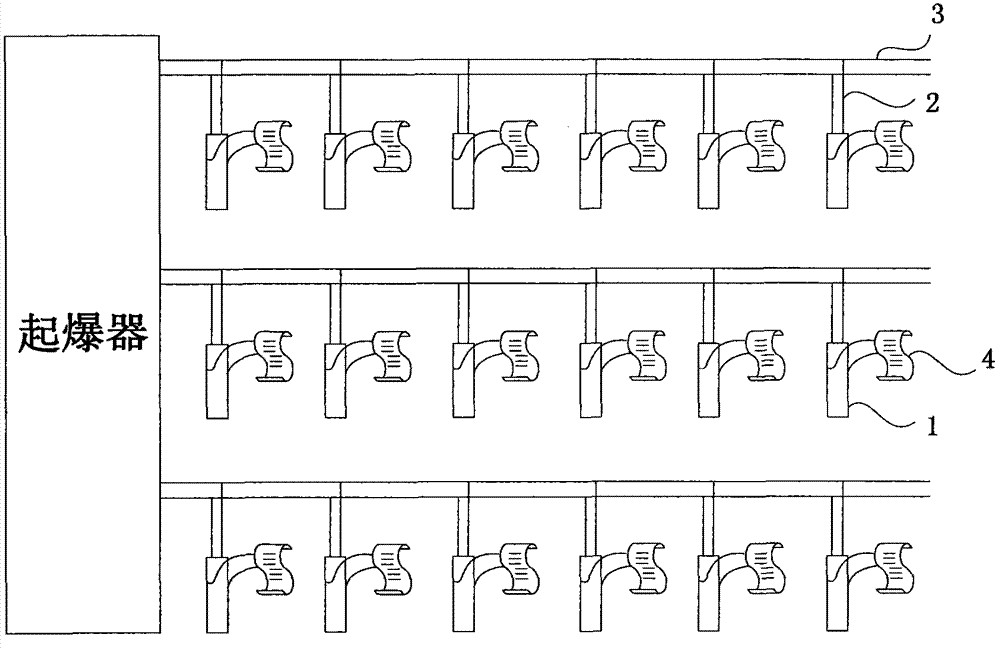

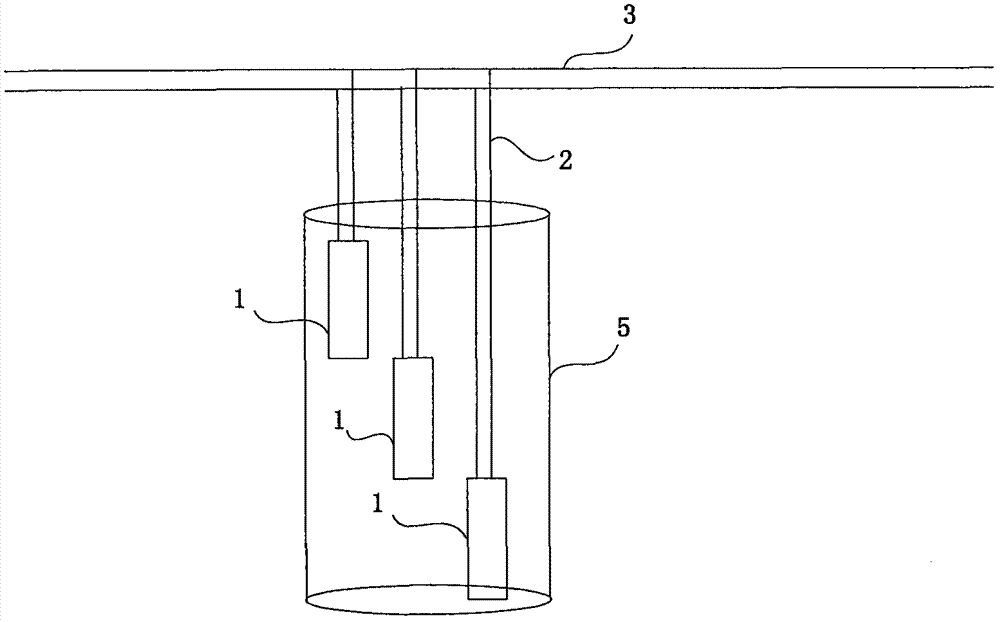

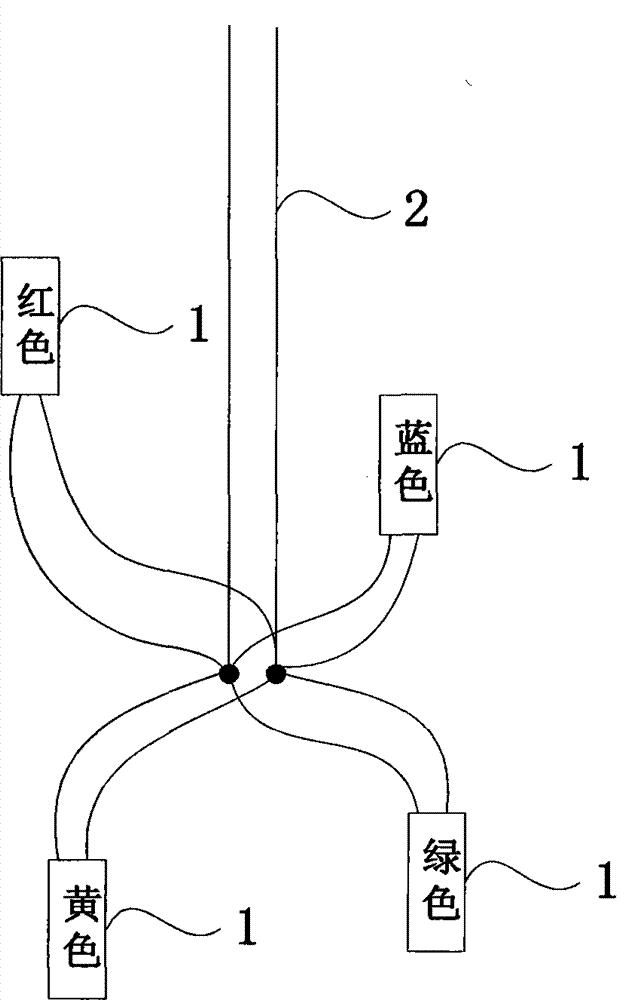

Communication method for multiple electronic detonators with shared leg wire

InactiveCN103884245AAvoid the construction processImprove reliabilityAmmunition fuzesCommunication designDetonation

The invention discloses a communication method for multiple electronic detonators with a shared leg wire in the technical field of connection and communication design of electronic detonators. The method comprises the following steps: connecting multiple electronic detonators with different types of preset codes in parallel in the same leg wire; connecting the leg wire with an electronic detonator characteristic reader; respectively transmitting the type codes and characteristic information to the multiple electronic detonators connected to the leg wire in parallel by the electronic detonator characteristic reader; after the electronic detonators connected to the leg wire in parallel receive the type codes and characteristic information, storing the characteristic information and transmitting response information when the type codes transmitted by the electronic detonator characteristic reader are judged to be consistent with preset type codes; disconnecting connection between the leg wire and the electronic detonator characteristic reader after the characteristic information is stored in each electronic detonator which is connected in parallel with the leg wire, and connecting the leg wire into a detonation branch. The communication and recognition problems in the process of sharing the same leg wire among the multiple electronic detonators are solved, the construction convenience is improved, and the miss-fire rate of the electronic detonators is reduced.

Owner:徐宁涛

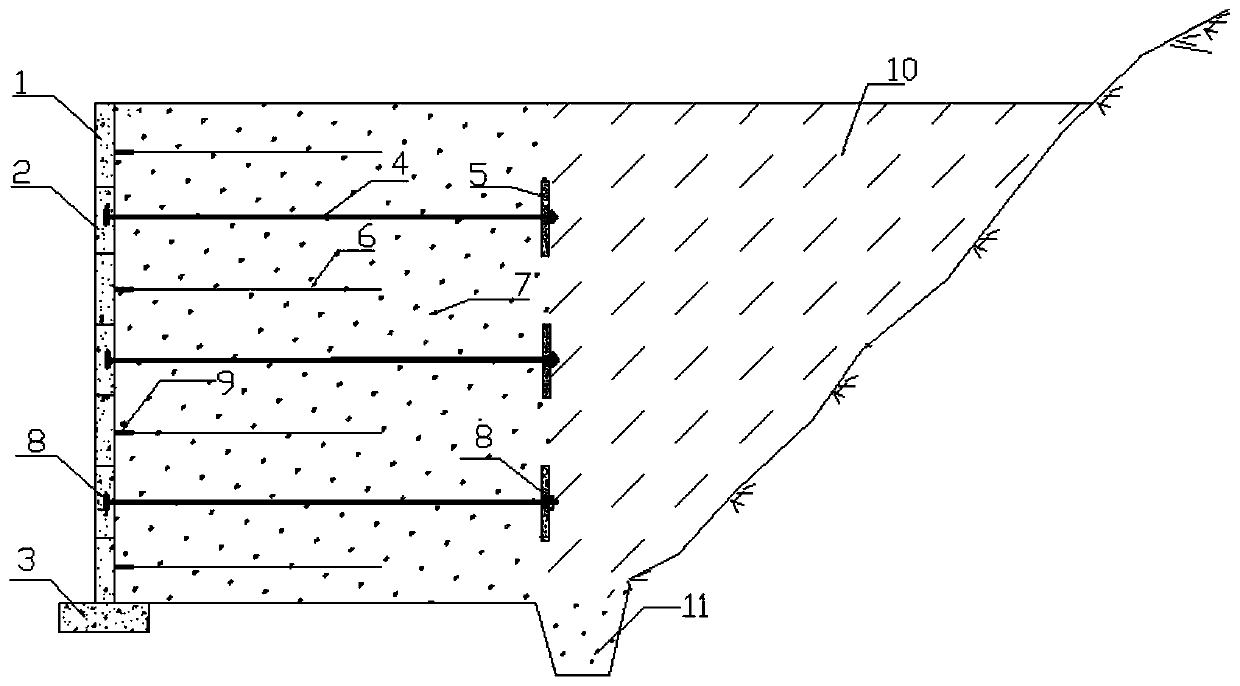

A hybrid reinforced retaining wall

ActiveCN107524159BLimit the use of high-strength featuresThe force is clear and reasonableArtificial islandsUnderwater structuresPre stressFace sheet

The invention discloses a mixed reinforced retaining wall. The mixed reinforced retaining wall comprises an ordinary wall panel, a prestressed wall panel, a wall panel base, non-bonding prestressed tendons, side pressing plates, geogrids and filler, wherein the ordinary wall panel and the prestressed wall panel are supported on the wall panel base; the prestressed wall panel is connected with the non-bonding prestressed tendons; the ordinary wall panel is connected with the grogrids; one or more grogrids are arranged between the two vertical non-bonding prestressed tendons; one ends of the non-bonding prestressed tendons are connected with the side pressing plates; and the other ends of the non-bonding prestressed tendons are stretched and anchored on the prestressed wall panel. According to the mixed reinforced retaining wall, a traditional reinforced soil technology is combined with a non-bonding prestressed reinforcement technology, the filler is passively restrained by reinforced soil fraction through the traditional reinforced soil technology, the active restraint strengthening action, of the non-bonding prestressed reinforcement technology, on the filler is exerted as well, economy of the non-bonding prestressed reinforcement technology is improved, and construction difficulty of the non-bonding prestressed reinforcement technology is reduced as well.

Owner:HUNAN UNIV

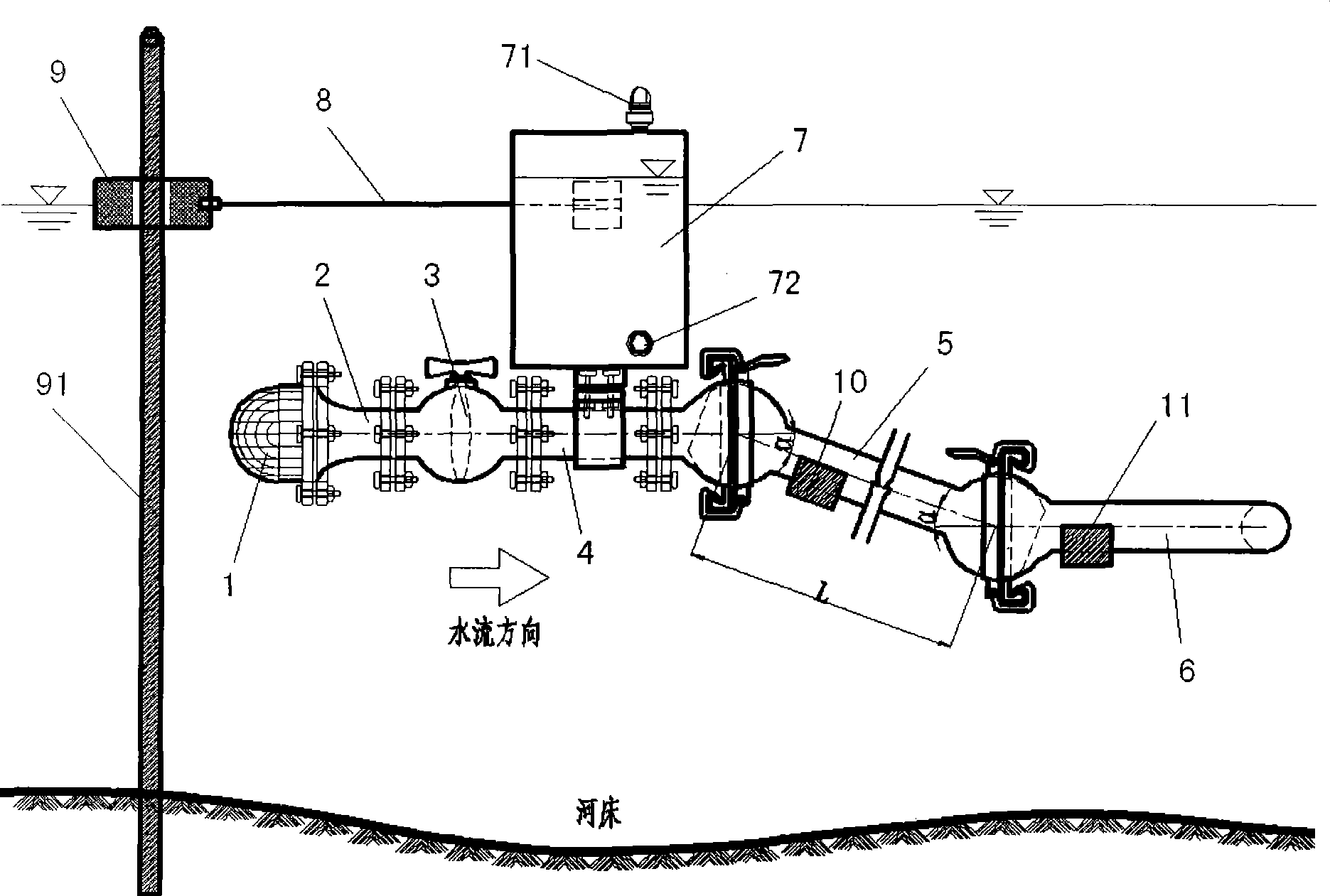

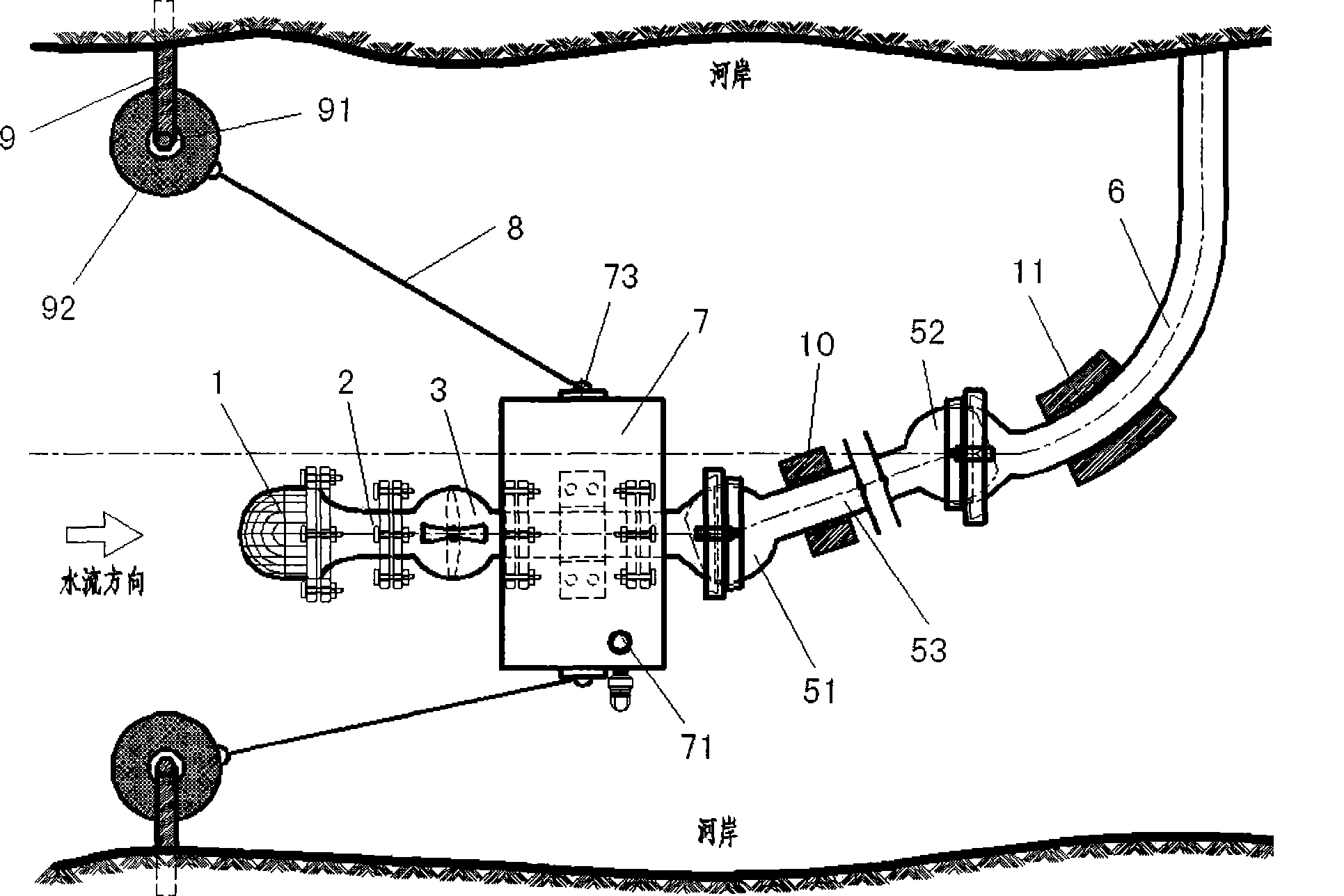

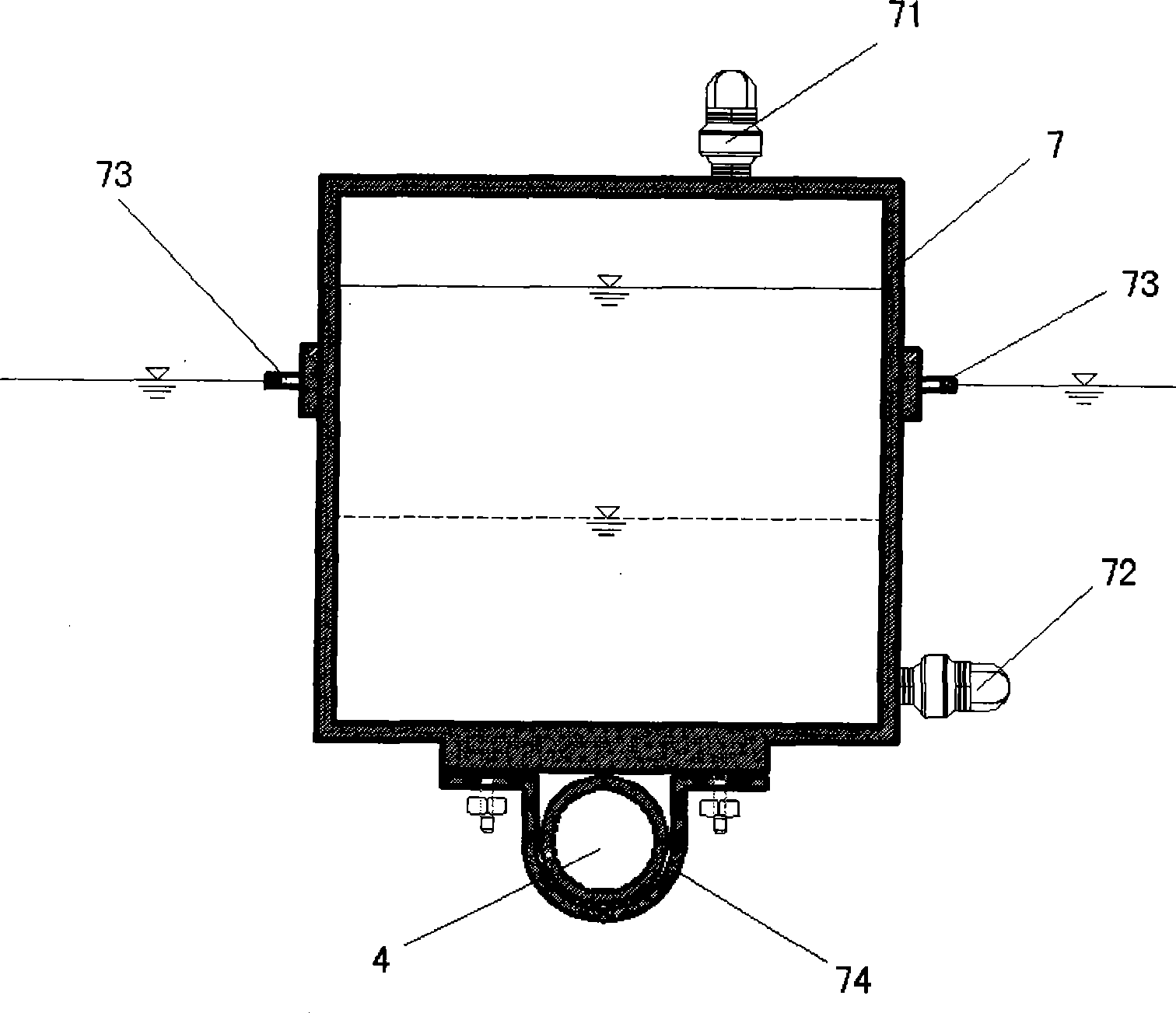

Adjustable intake apparatus for hydraulic power plant

InactiveCN101418562AAvoid siltingAvoid water inlet clogging problemsWater-power plantsConventional hydroenergy generationUniversal jointUnderwater

The invention relates to an adjustable water inlet device for a hydropower station, which is characterized in that the adjustable water inlet device for the hydropower station comprises a spherical strainer, a trumpet water inlet section, a control gate valve, a floating box assembly section, an adjusting section and an elbow pipe section, wherein a floating box is connected to the floating box assembly section; lower parts of the adjusting section and the elbow pipe section are provided with U-shaped floating blocks of a floating pipeline respectively; both sides of the floating box are connected to a mooring line device through steel cables respectively; the adjusting section consists of an upstream spherical universal joint, a downstream spherical universal joint and a connecting pipe which connects the upstream spherical universal joint and the downstream spherical universal joint; and an outlet of the elbow pipe section is connected with a fixed water conduit of a river bank. The adjustable water inlet device for the hydropower station does not require a matched dam project to maintain the underwater embedded depth of a water inlet, does not obstruct a river channel, is favorable for maintaining natural ecology of the river channel, and is widely suitable for the water inlet of a small diversion type hydropower station.

Owner:CHINA AGRI UNIV

Breather apparatus for engine

InactiveUS8505521B2Avoid complex constructionSuppression amountCombustion enginesCrankcase ventillationCylinder headEngineering

This breather apparatus has a rotation separator that is fastened to a camshaft, and that rotation separator has a base plate section and a plurality of protruding plates that extend from the base plate section. Moreover, a separator housing is provided in the cylinder head, and comprises an air intake on one end, and an exhaust outlet on the other end. Furthermore, a reed valve that opens and closes by the change in pressure inside a cam chamber is provided in the air intake. Blowby gas that is guided to the cam chamber hits against the protruding plates when passing in the radial direction of the rotation separator, and oil mist is captured by those protruding plates. Continuing, the blowby gas is guided from the cam chamber into the separator housing via the reed valve. When passing through the reed valve, the flow rate of the blowby gas changes, so oil mist is effectively captured by the inner wall surface of the separator housing.

Owner:SUBARU CORP

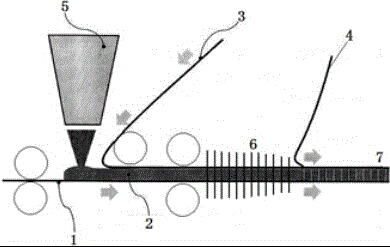

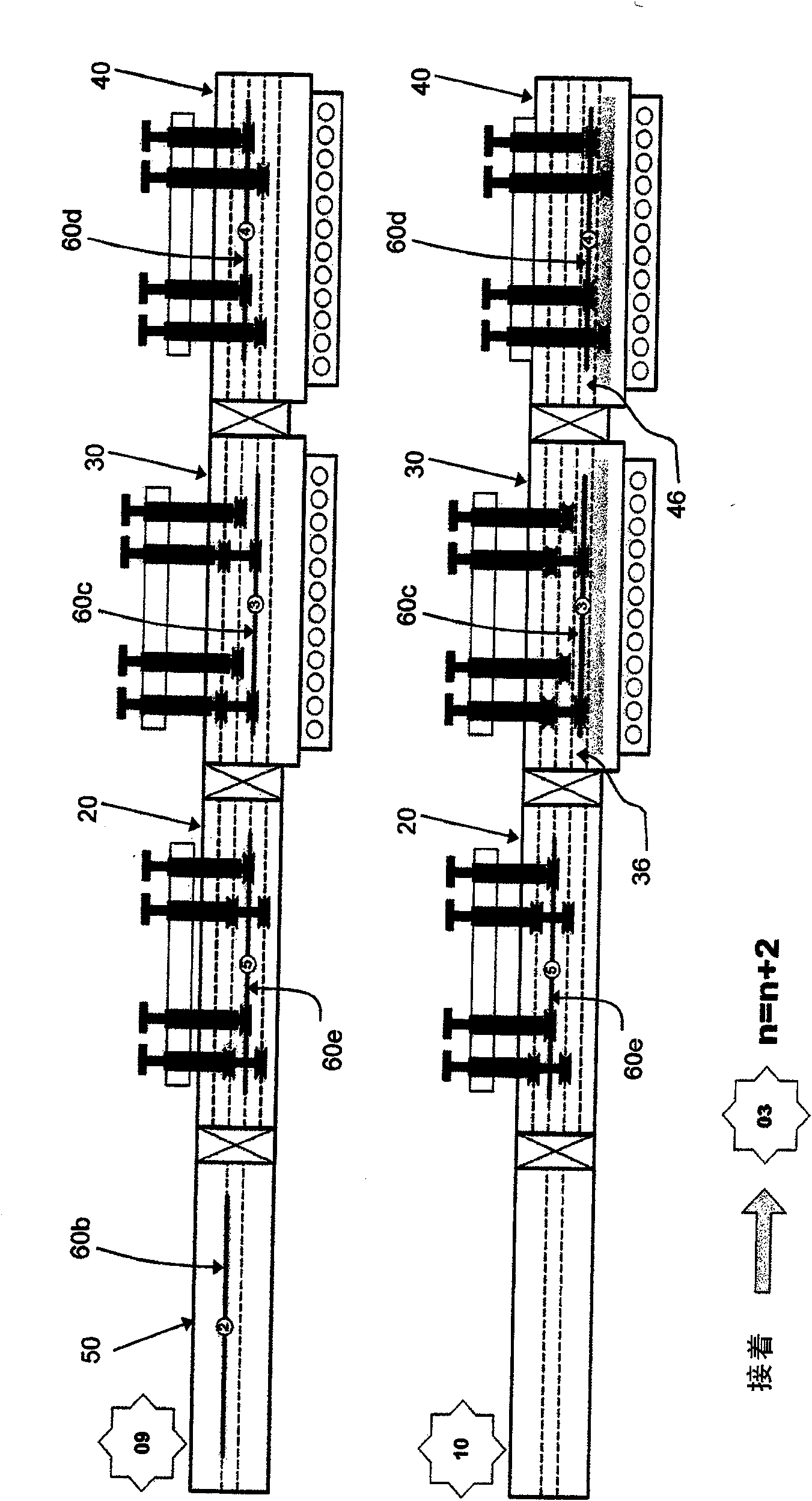

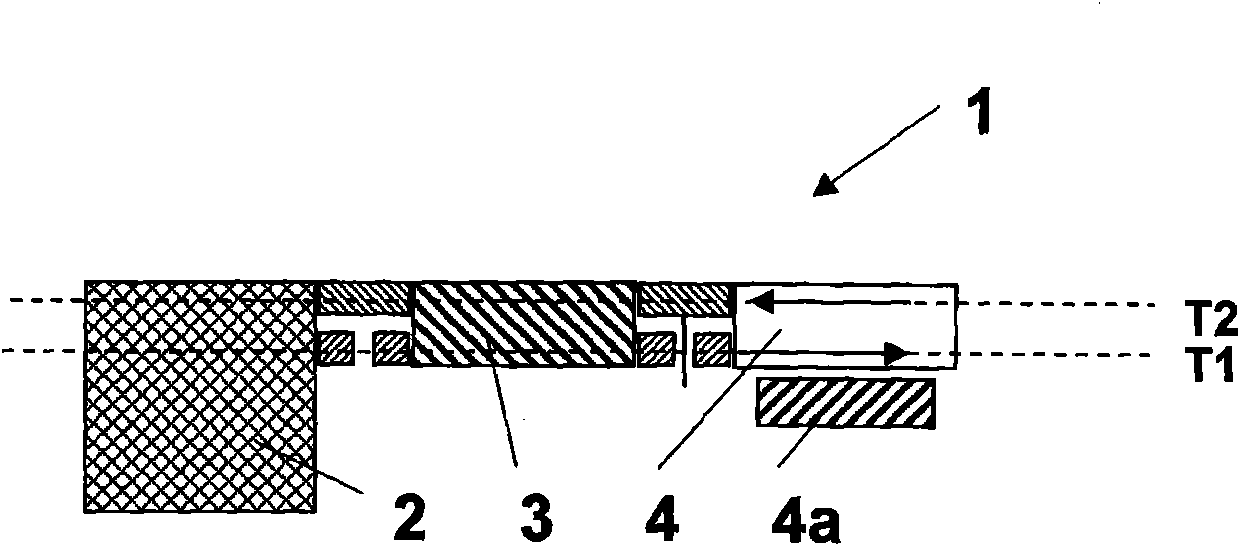

Processing system and method of operating a processing system

ActiveCN102112647AImprove efficiencyIncrease productionVacuum evaporation coatingSemiconductor/solid-state device manufacturingCoating systemTreatment system

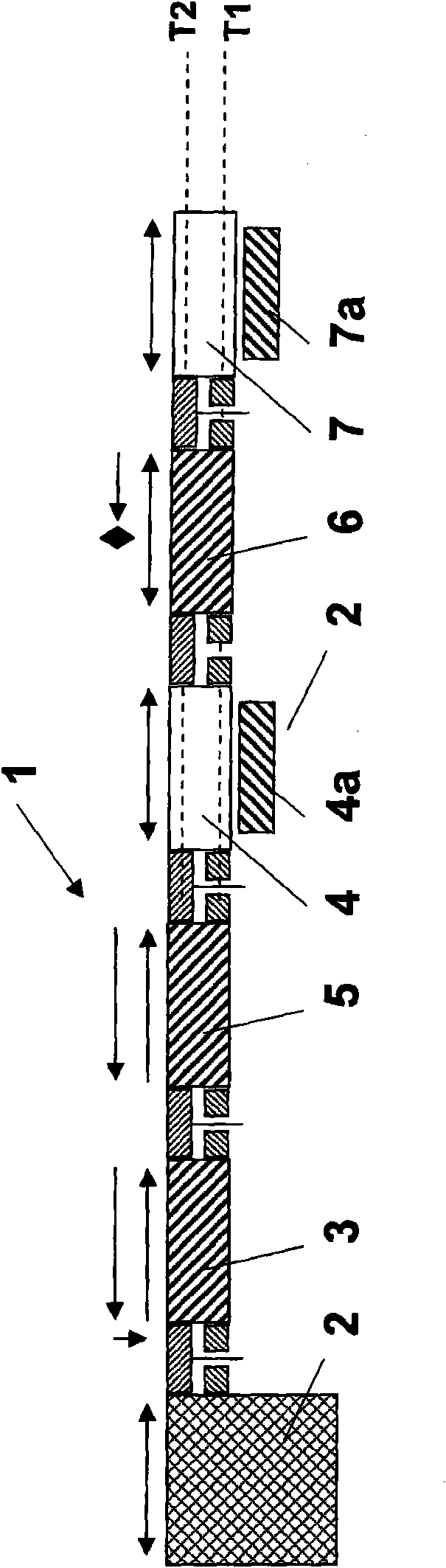

The invention provides a processing system and a method of operating the processing system. A coating system 1 comprises a swing station 2 including a swing module and an arrangement of chambers. The arrangement of chambers comprises a lock chamber 3 and a first coating chamber 4. The lock chamber 3 is configured as a combined lock-in / lock-out chamber. The arrangement of chambers has a first substantially linear transport path T1 indicated by dashed lines, and a second substantially linear transport path T2 indicated by dashed lines. The arrangement of the paths T1 and T2 establishes a dual track. The system 1 includes a transport system for moving a substrate through the arrangement of chambers 3, 4 along the first transport path T1 and / or along the second transport path T2 as indicated by arrows. One or particularly both chambers 3 and 4 comprise transfer means for transferring the substrate / carrier from the first path T1 to the second path T2 by a lateral movement of a dual or triple track section and / or from the second path T2 to the first path T1.

Owner:APPLIED MATERIALS INC

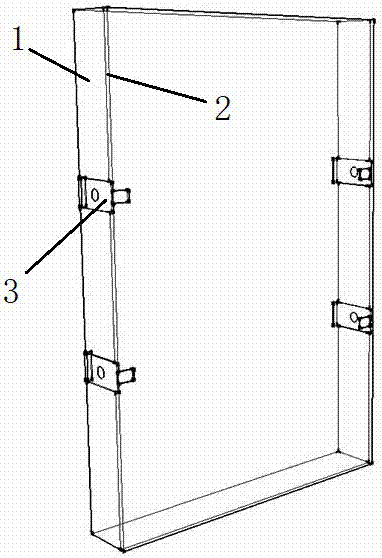

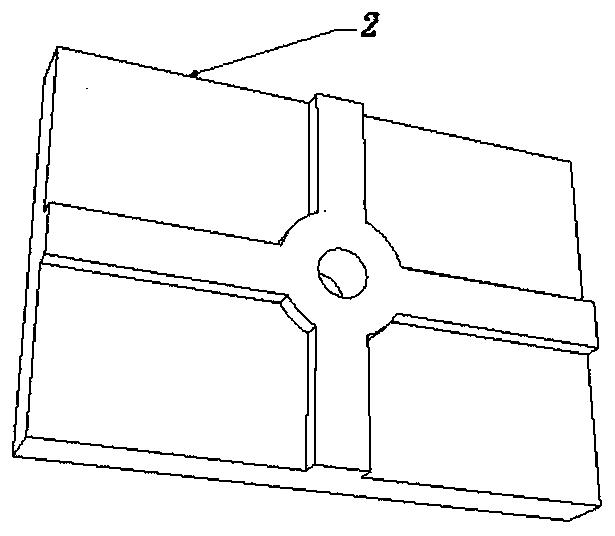

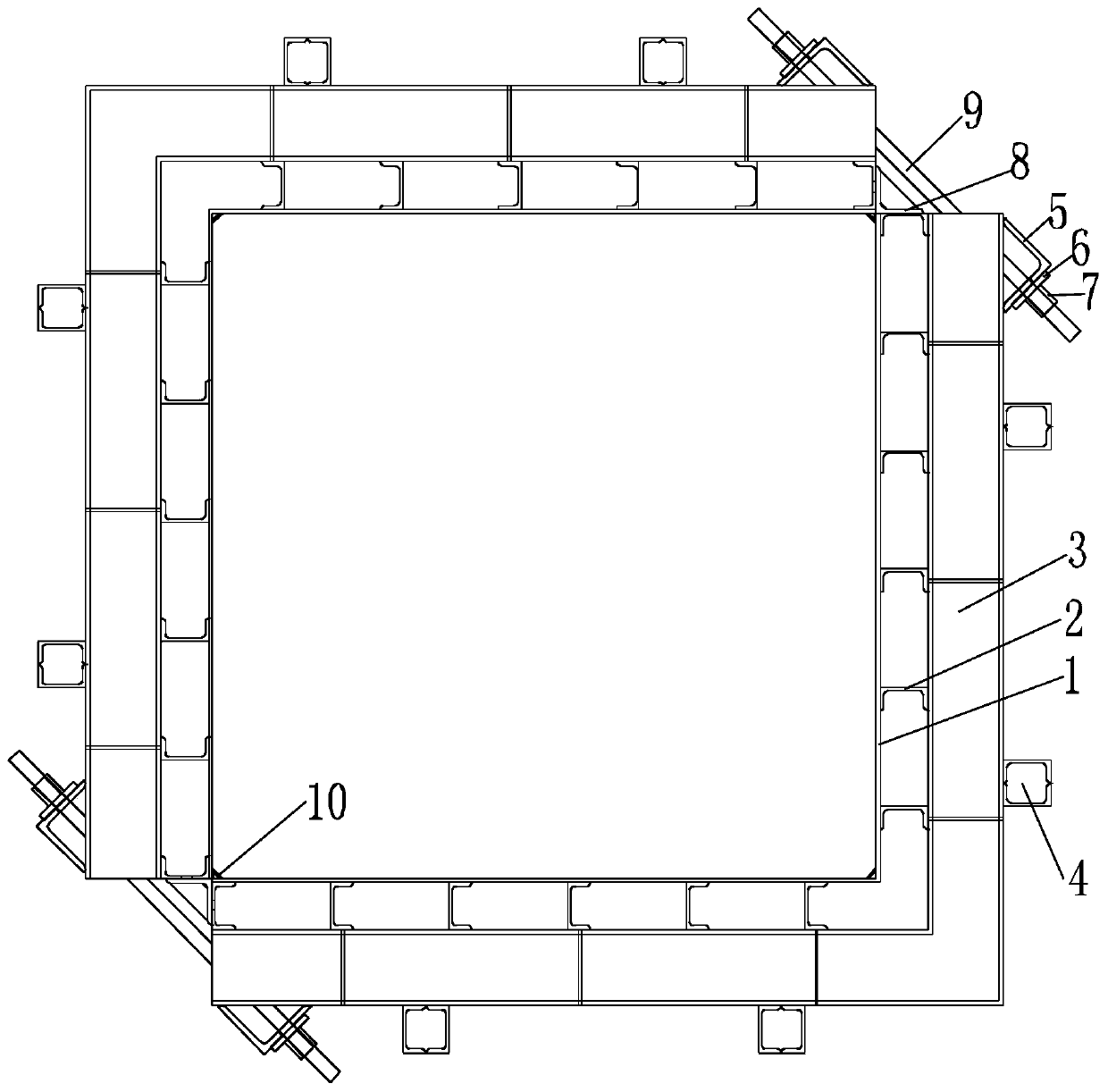

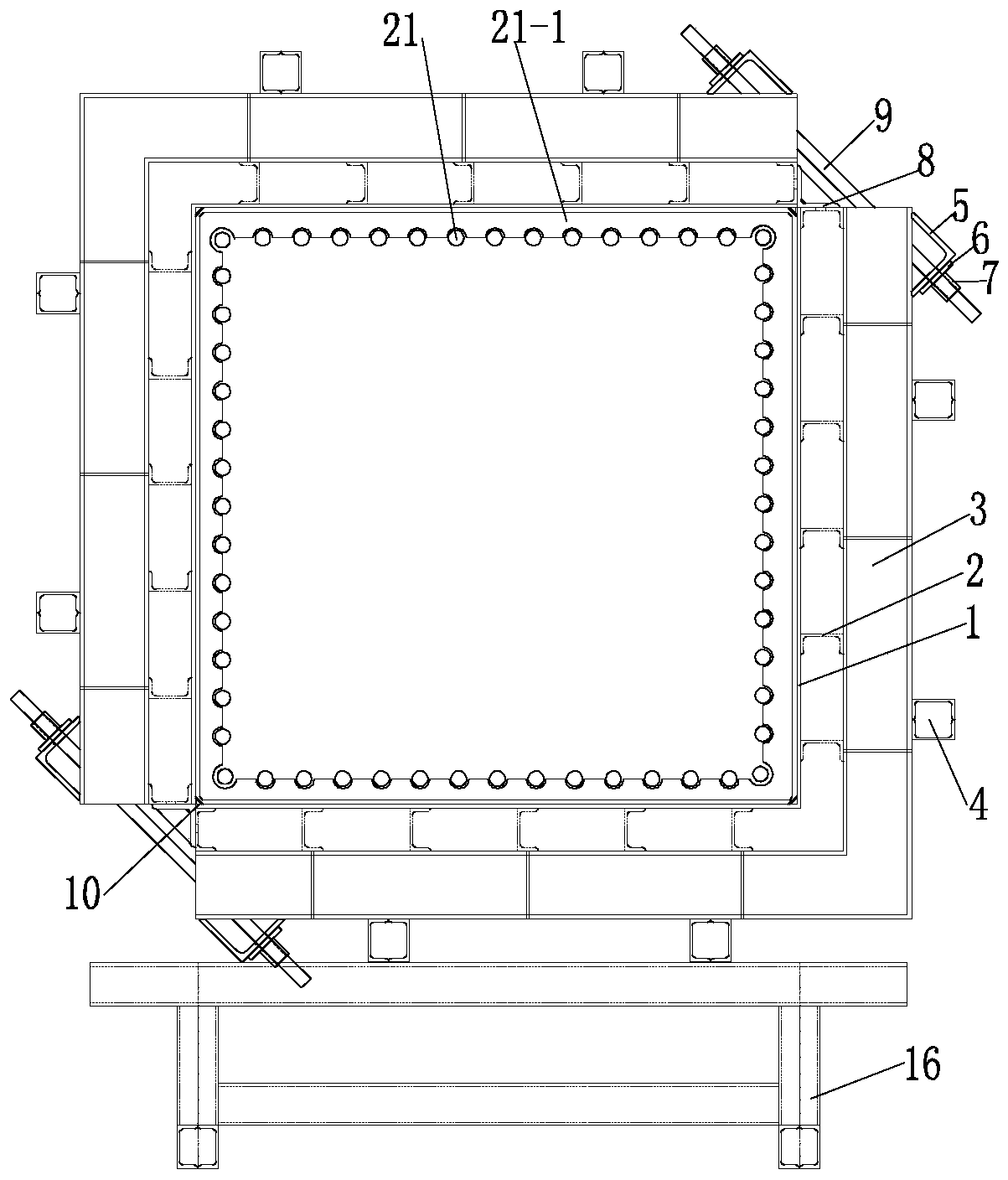

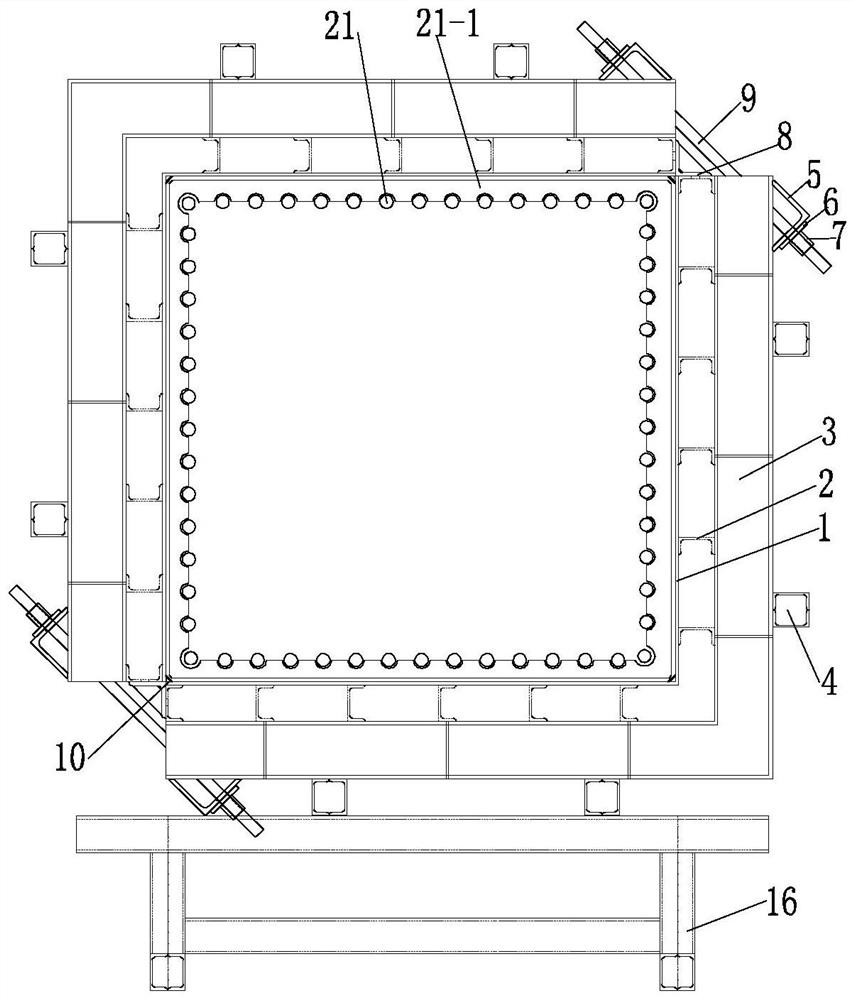

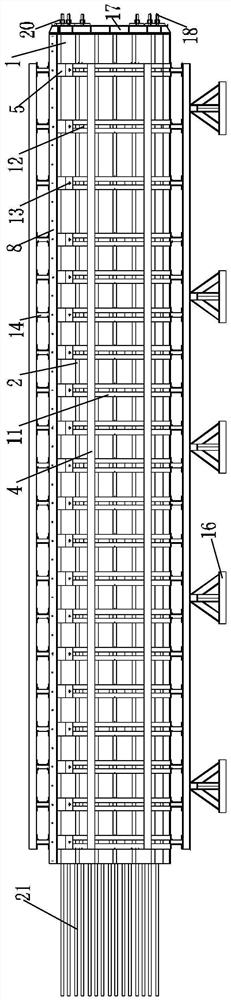

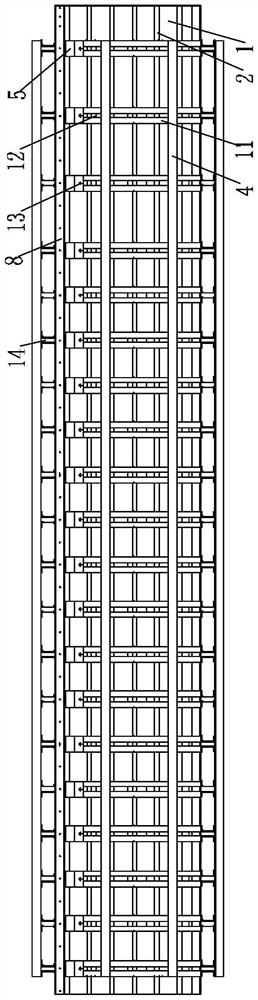

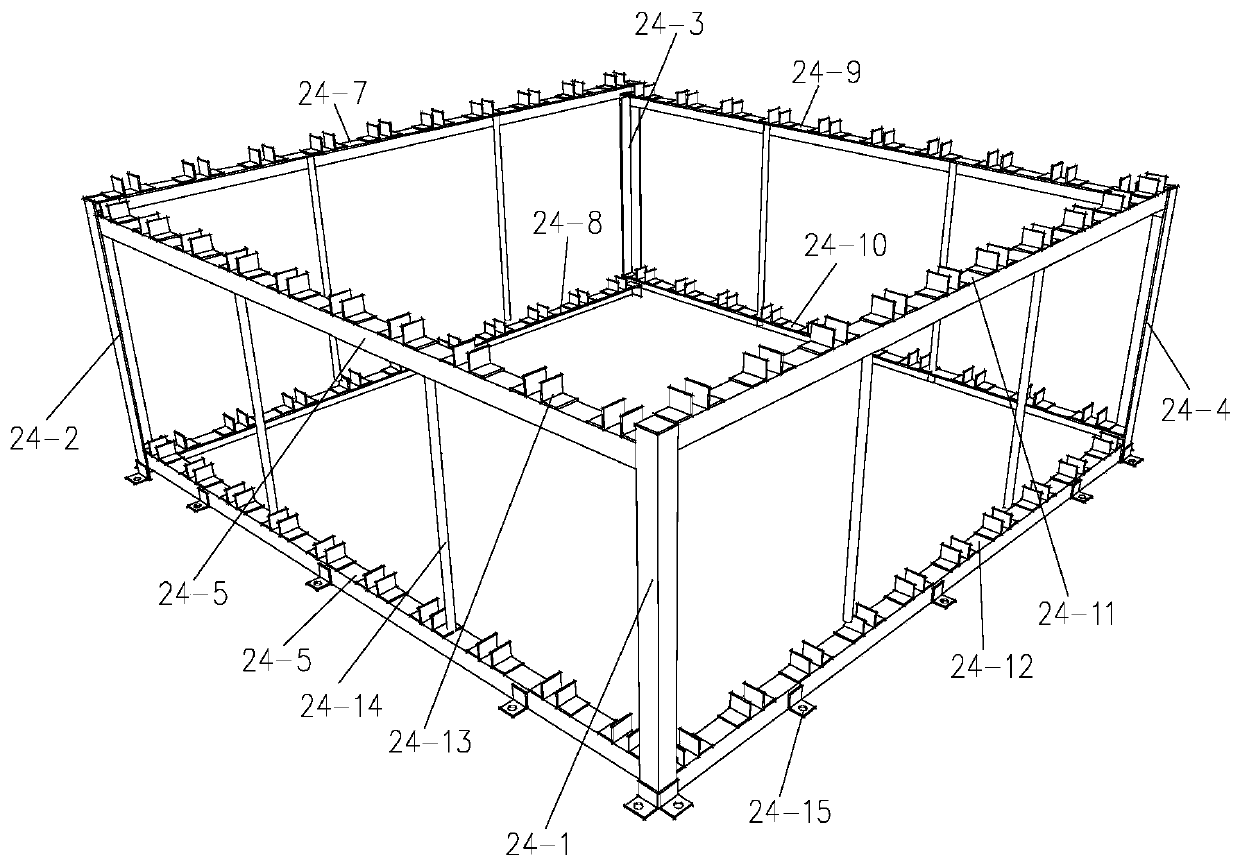

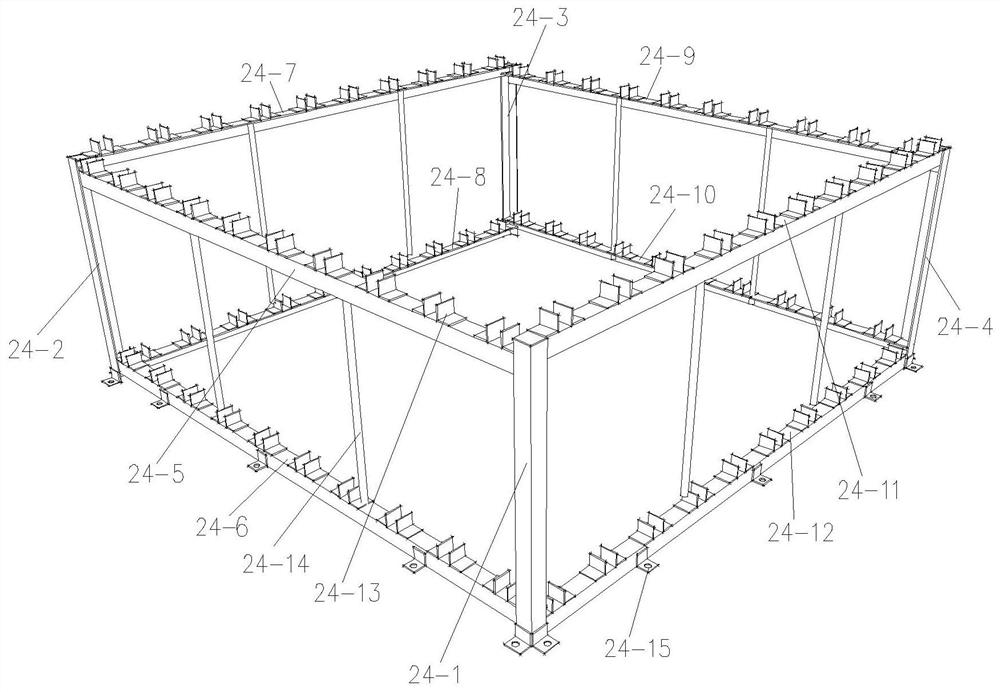

Steel formwork and manufacturing method thereof

InactiveCN110206294AReduce peripheral volumeAvoid complex constructionForms/shuttering/falseworksForming/stuttering elementsElement modelTransverse pressure

The invention discloses a steel formwork and a manufacturing method thereof. The steel formwork comprises first L-shaped steel supporting formworks and second L-shaped steel supporting formworks whichare the same in structure and size, and each first L-shaped steel supporting formwork sequentially comprises an L-shaped steel face plate, a secondary rib layer, a primary rib layer and a reinforcinglayer from inside to outside. The manufacturing method comprises the steps that first, the specifications of the steel formwork are planned; second, the total load borne by the steel formwork is obtained; third, the design deformation amount of the steel formwork is calculated; fourth, a finite element model of the steel formwork is established, and the strength and the deflection of the steel formwork are verified; and fifth, the steel formwork is manufactured. The steel formwork with the four sealed walls is formed by the first L-shaped steel supporting formworks and the second L-shaped steel supporting formworks in an assembled mode, the steel formwork is fastened to the connection positions of the first L-shaped steel supporting formworks and the second L-shaped steel supporting formworks through a plurality of tie bars, through design of double L-shaped transverse pressure-bearing plates, the self weight of the steel formwork is decreased while the lateral pressure is ensured, and a gap between the L-shaped transverse pressure-bearing plates allows the tie bars to be inserted.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

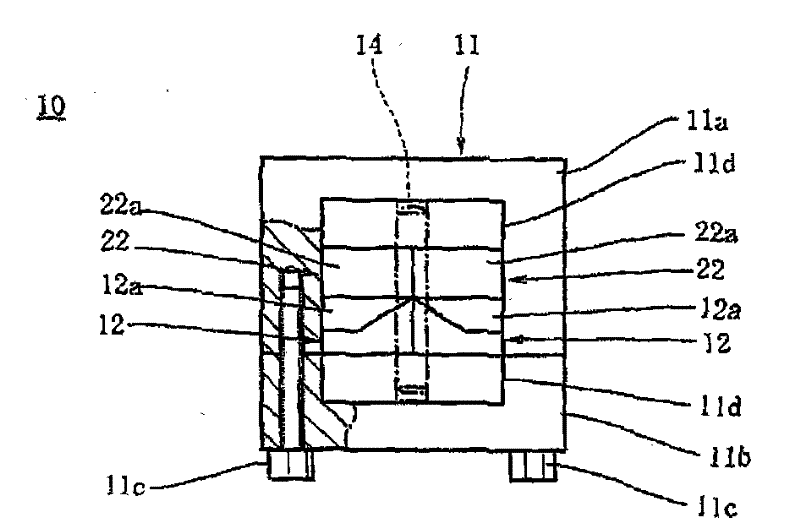

Switching operating device and object cutting method

ActiveCN102218750AReduce wasteAvoid complex constructionMetal working apparatusEngineeringMechanical engineering

The invention provides a switch operating device. The switch operating device comprises a frame (11); a pair of cutting rod bodies (12) axially supported on the front of the frame (11) and forming a cutting part (12a) on the top side; and a cutting slide block (18) driven by a driving mechanism (13) to move and making the cutting part perform switch operations. The device further comprises a pair of clamping rod body (22) located adjacent to the pair of cutting rod bodies, axially supported on the front of the frame (11) and forming a clamping part (22a) located on the top side and side by side with the cutting part; a clamping slide block (23) located adjacent to the cutting slide block (18), slidingly accommodated in the frame (11) and making the clamping part to perform switch operations by moving in the same direction as the cutting slide block (18) does; a force application unit (26) for exerting force on the clamping slide block (23) towards a direction where the clamping slide block performs closing operations to the clamping part; a relative movement limiting unit (30) limiting the relative movement of the cutting slide block (18) and the clamping slide block (23) and banning that the stretching angle of the clamping part is smaller than that of the cutting part.

Owner:NITTOKU ENG CO LTD

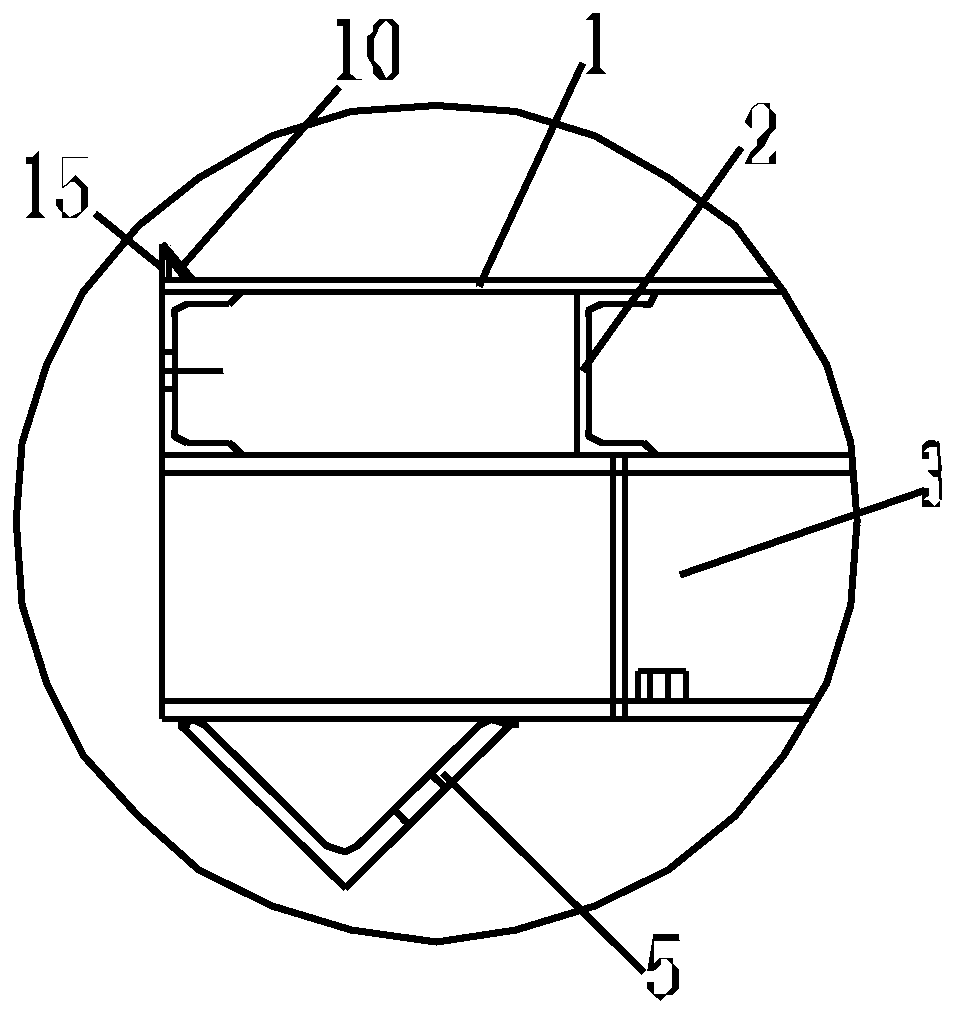

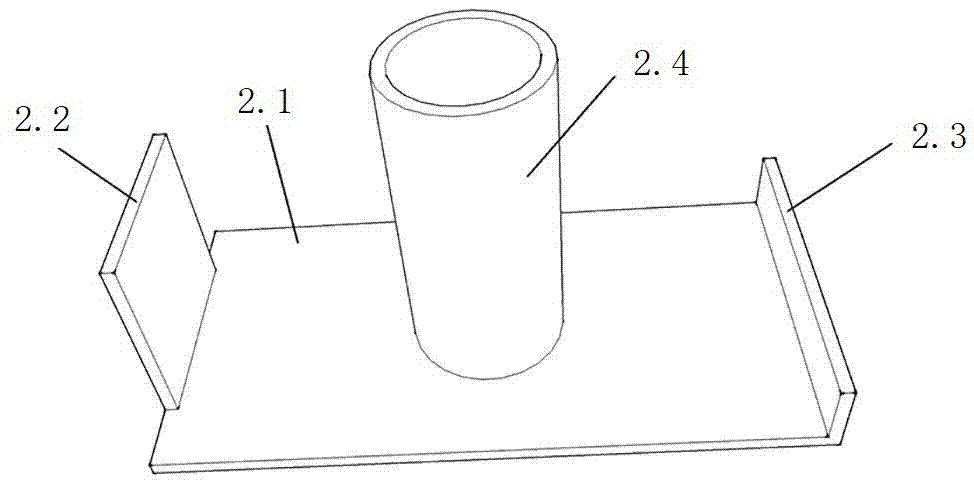

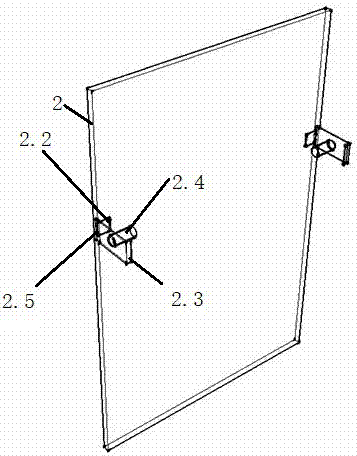

Reinforcement cage and steel formwork integrated transverse fabrication structure

ActiveCN110206304AReduce peripheral volumeAvoid complex constructionForms/shuttering/falseworksBuilding reinforcementsRebarBuilding construction

The invention discloses a reinforcement cage and steel formwork integrated transverse fabrication structure, which comprises a fabricating platform and a jack matched with the steel formwork. A reinforcement cage is placed into a steel formwork, and the top end of the steel formwork is fixedly connected with the jack through a steel formwork top sealing plate; the end, at the top end of the steelformwork, of a main reinforcement in the reinforcement cage is externally provided with an external thread; the two ends of a main reinforcement connecting pipe are provided with external threads correspondingly; the end, at the top end of the steel formwork, of the main reinforcement in the reinforcement cage is in threaded connection with one end of the main reinforcement connecting pipe througha main reinforcement connecting sleeve provided with an internal thread; and the other end of the main reinforcement connecting pipe penetrates through a gap of the jack to be in threaded connectionwith a main reinforcement fixing sleeve provided with an internal thread. Through assembly of a first L-shaped steel support formwork and a second L-shaped steel support formwork, the reinforcement cage is placed into the steel formwork, through cooperation of the jack, the main reinforcement connecting pipe, the main reinforcement connecting sleeve and the main reinforcement fixing sleeve, the reinforcement cage and the steel formwork are fixed into a whole, later overall hoisting of the reinforcement cage and the steel formwork is facilitated, and thus the construction process is simplified.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

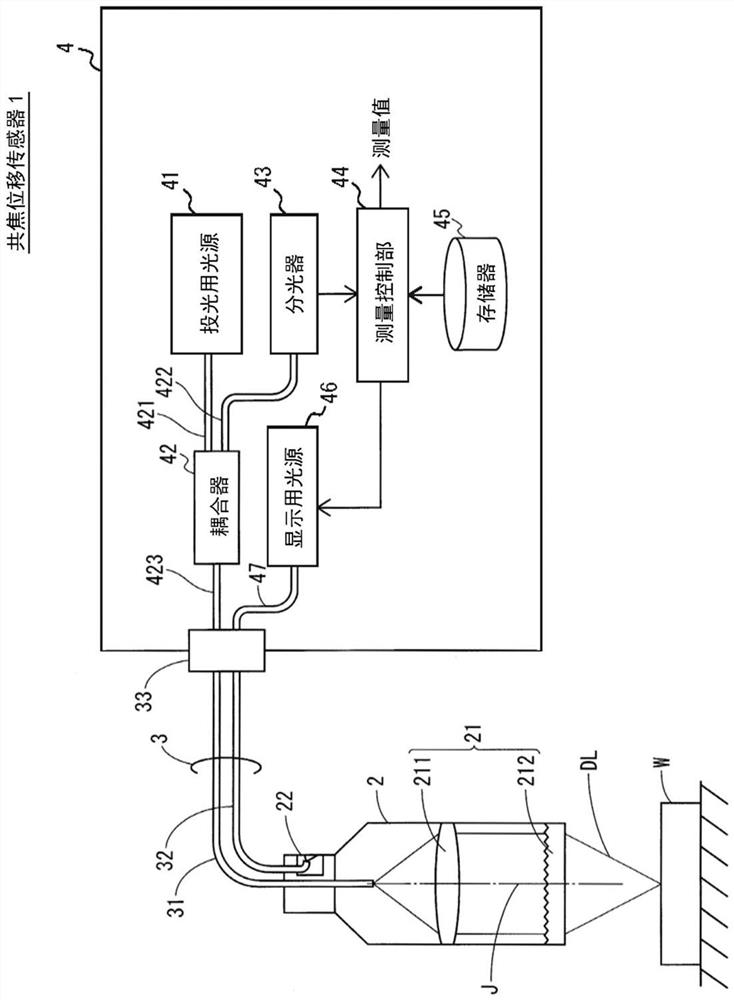

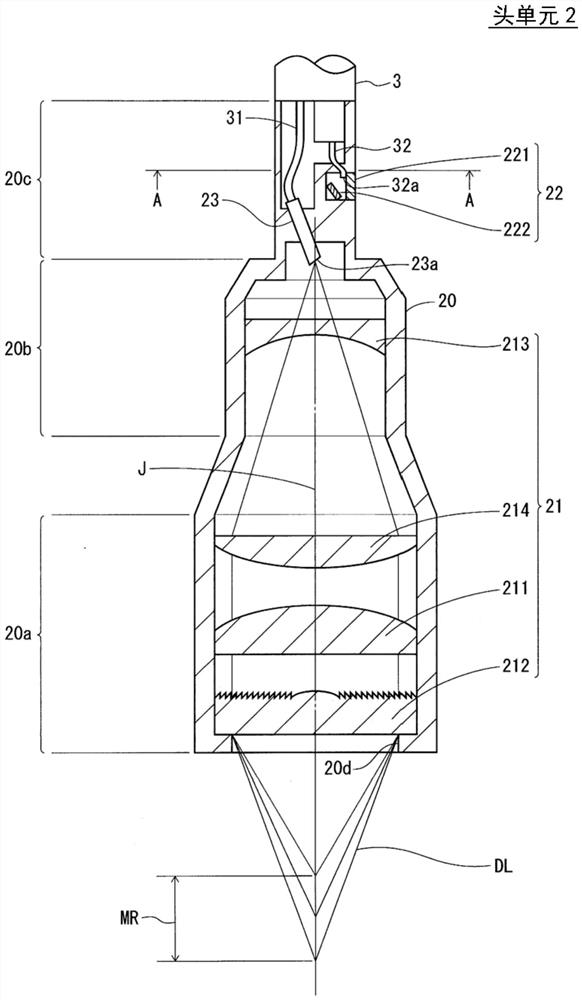

Confocal Displacement Sensor

ActiveCN109084685BEasy to identifyAvoid complex constructionUsing optical meansEngineeringLight signal

Owner:KEYENCE

An integrated horizontal assembly structure of reinforcement cage and steel formwork

ActiveCN110206304BReduce peripheral volumeAvoid complex constructionForms/shuttering/falseworksBuilding reinforcementsRebarScrew thread

The invention discloses an integrated horizontal assembly structure of a reinforcing bar cage and a steel formwork, comprising an assembly platform and a top support matched with the steel formwork. Fixed connection, one end of the main reinforcement in the reinforcement cage located at the top of the steel formwork is provided with external threads, both ends of the main reinforcement connection pipe are provided with external threads, one main reinforcement in the reinforcement cage is located at the top end of the steel template and one end of the main reinforcement connection pipe The other end of the main rib connecting pipe is threadedly connected with the main rib fixing sleeve provided with the internal thread through the jacking gap through the main rib connecting sleeve provided with the internal thread. In the invention, the reinforcement cage is placed in the steel template by assembling the first L-shaped steel support template and the second L-shaped steel support template, and the reinforcement cage is assembled by the cooperation of the top bracket, the main reinforcement connection pipe, the main reinforcement connection sleeve and the main reinforcement fixing sleeve. It is integrated with the steel formwork, which is convenient for the overall hoisting of the steel cage and the steel formwork in the later stage and simplifies the construction process.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

Integrated horizontal assembly method of reinforcement cage and steel formwork

ActiveCN110206306BHigh input costFlexible useForms/shuttering/falseworksBuilding reinforcementsRebar

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

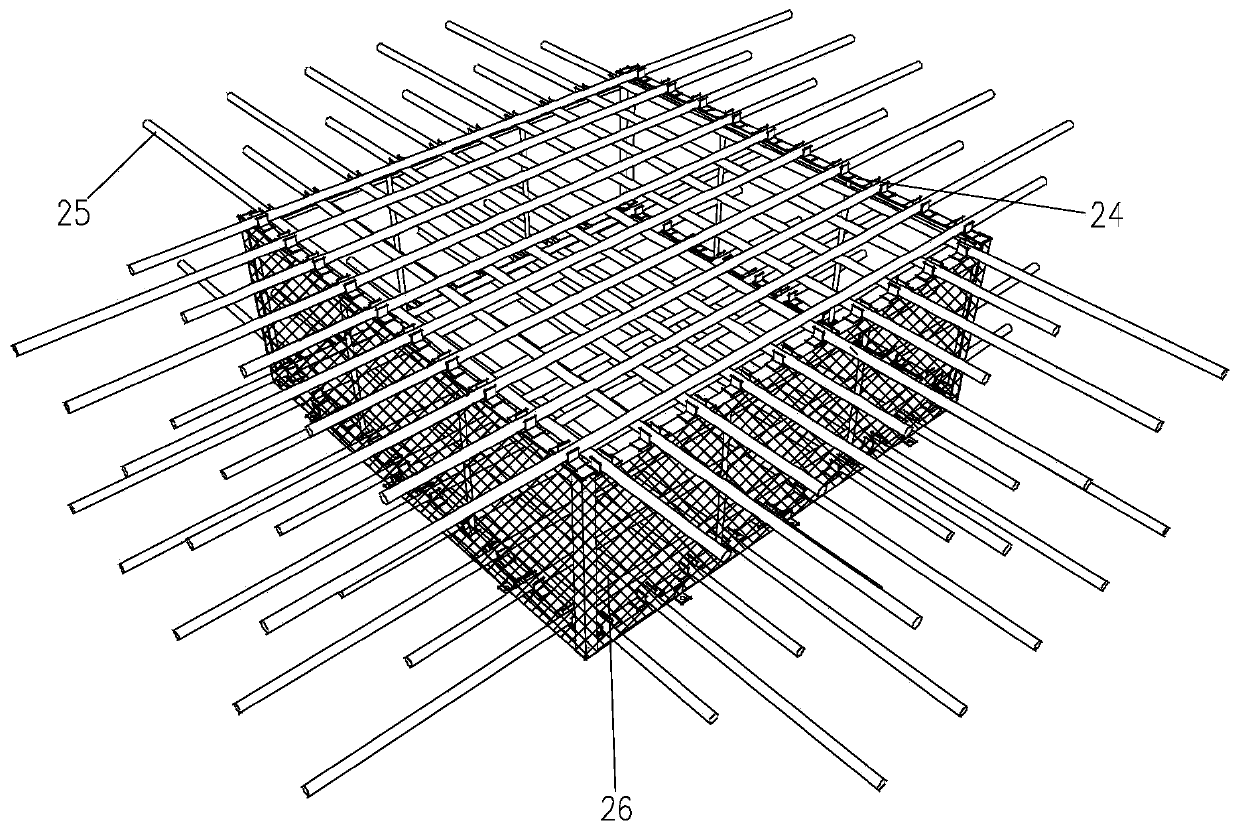

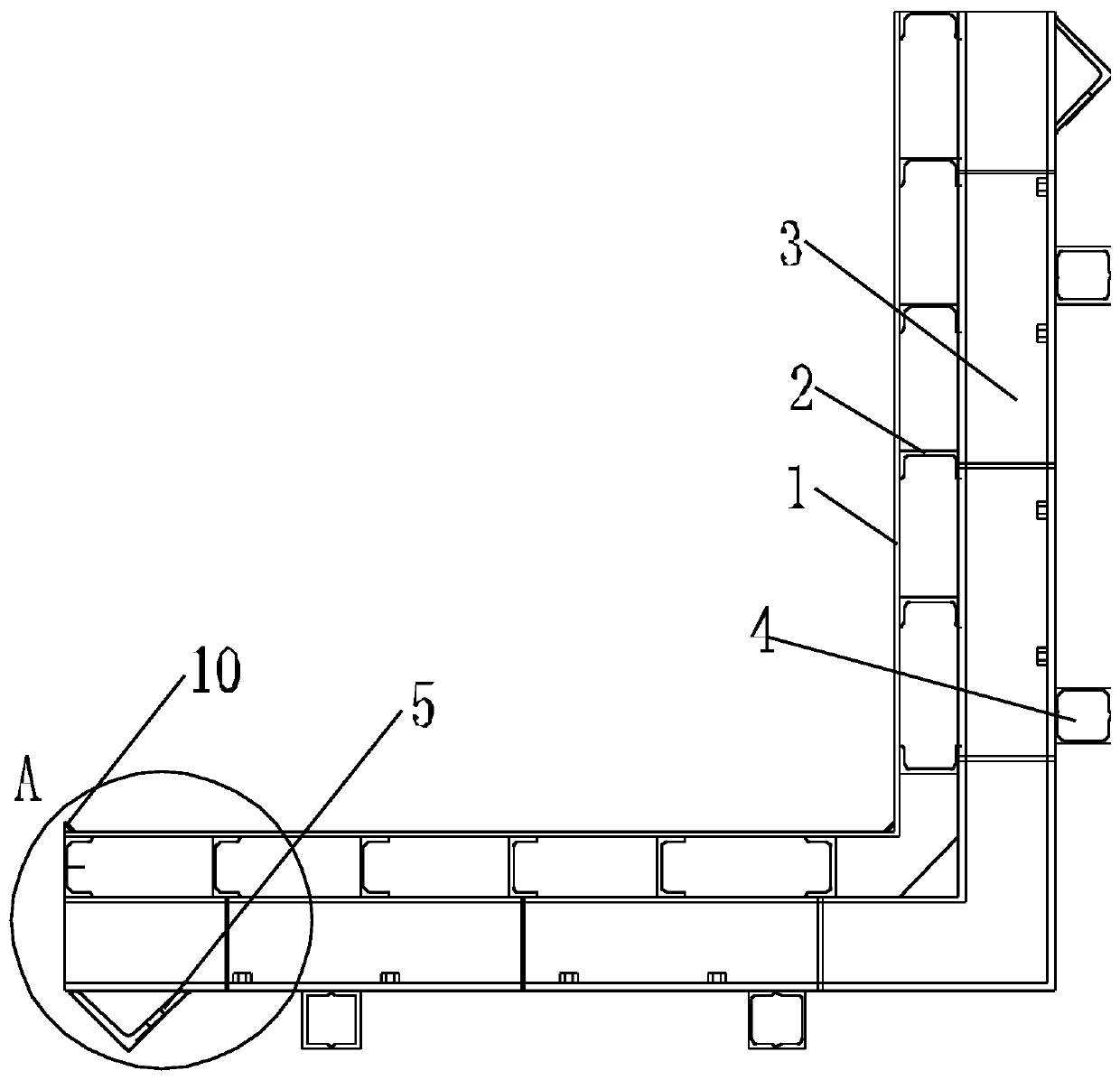

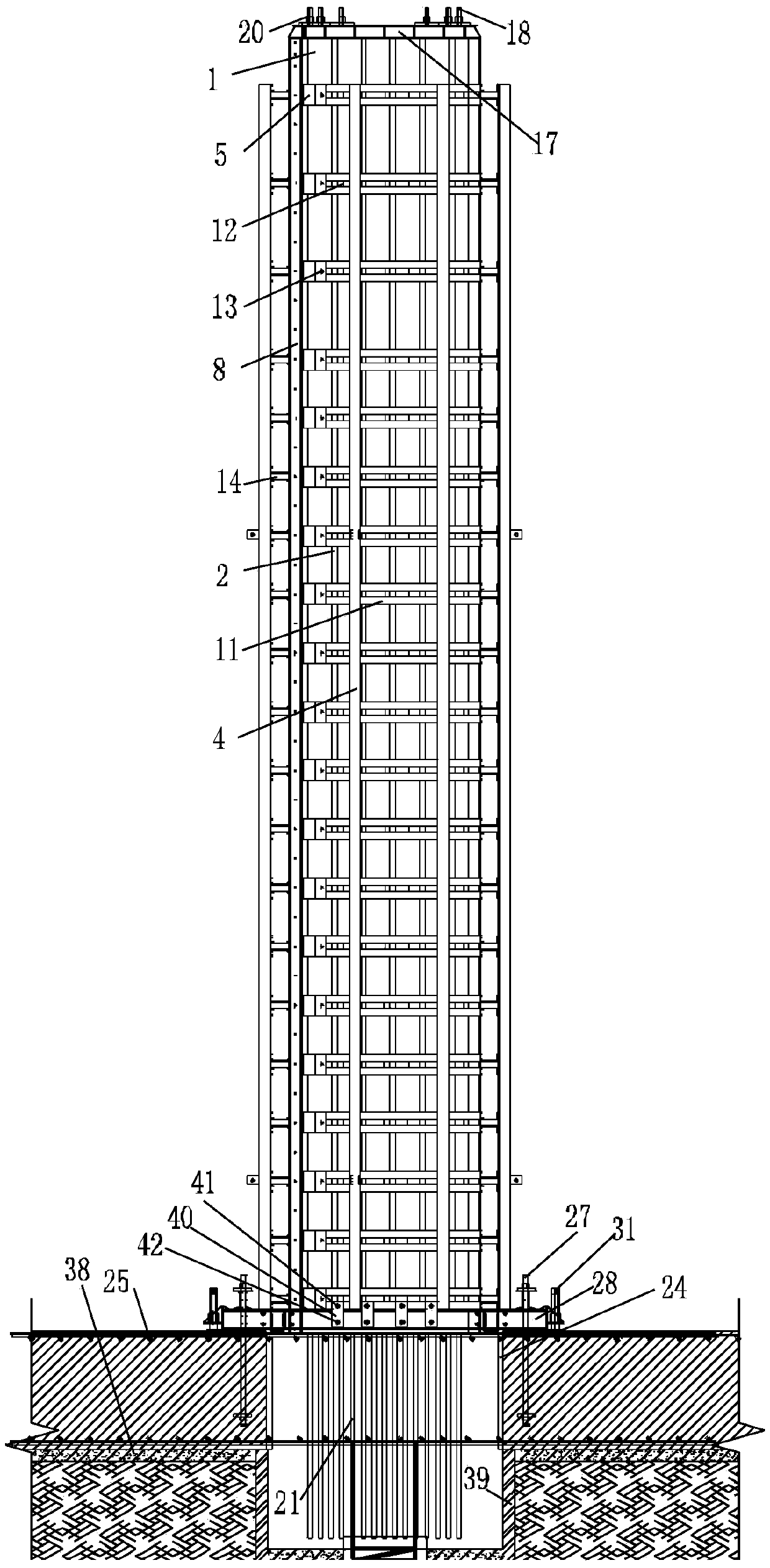

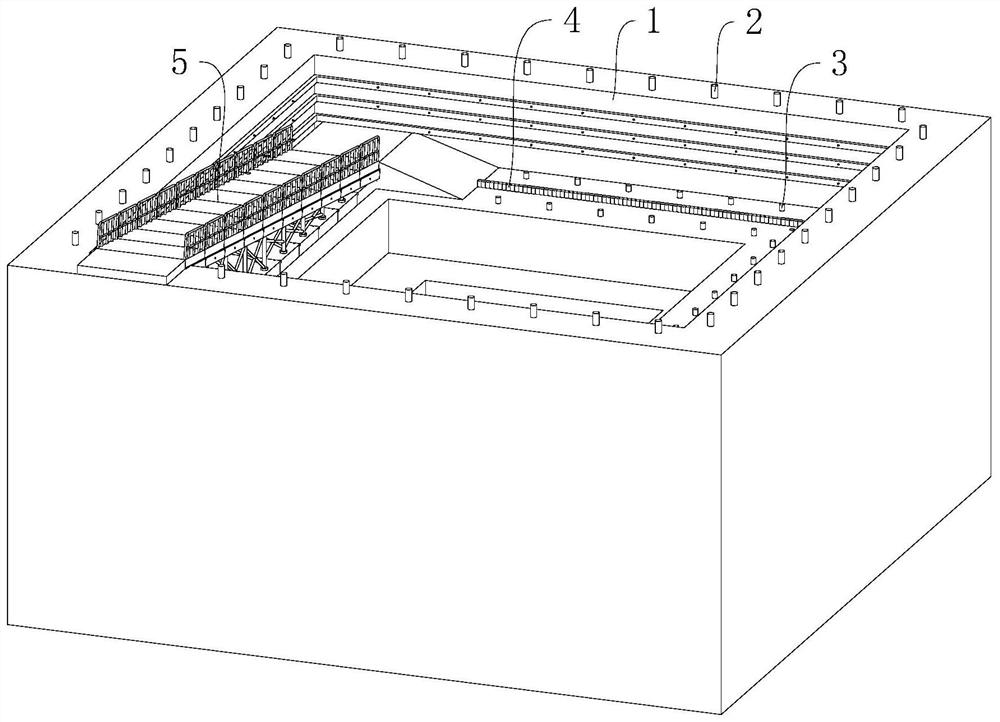

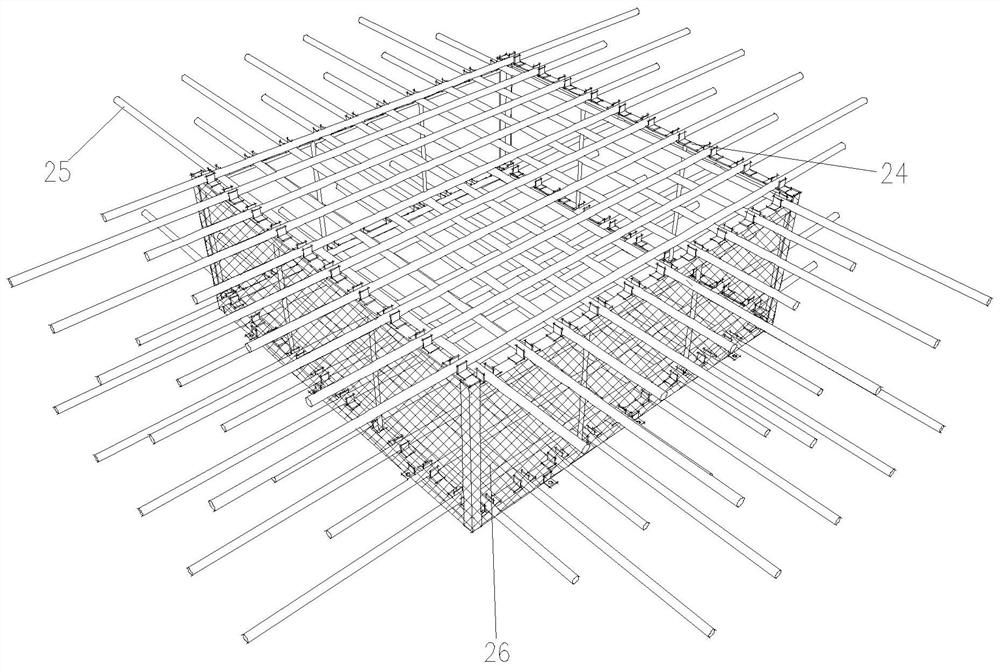

Rebar cage and steel formwork integral direct anchoring positioning structure

ActiveCN110206305AEasy to liftAvoid complex constructionForms/shuttering/falseworksBuilding reinforcementsEngineeringRebar

The invention discloses a rebar cage and steel formwork integral direct anchoring positioning structure. The rebar cage and steel formwork integral direct anchoring positioning structure comprises a positioning foundation and a rebar cage and steel formwork integrated structure, the rebar cage and steel formwork integrated structure is in direct anchoring fit with the positioning foundation through a lifting appliance, the positioning foundation comprises a raft foundation and a steel formwork positioning frame arranged on a reserved opening in the raft foundation, and the reserved opening ofthe raft foundation is located over a reserved pit of a reserved column sinking foundation. By assembling a first L-shaped steel supporting formwork and a second L-shaped steel supporting formwork, arebar cage is placed in a steel formwork, the rebar cage and the steel formwork are fixed into a whole through cooperation of a top support, a main bar connecting pipe, a main bar connecting sleeve and a main bar fixing sleeve, the mounting position of a raft rebar transversely penetrating through the reserved opening is positioned through a raft rebar positioning frame, collision or blocking generated when the raft rebar is inserted into a rebar cage main bar in a penetrating mode in the later period is avoided, and the position of the steel formwork in the rebar cage and the steel formwork which are integrally connected is positioned through the steel formwork positioning frame, and the construction processes are simplified.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

Super high-rise building deep foundation pit and construction method thereof

The invention relates to a super high-rise building deep foundation pit which comprises a foundation pit body. The foundation pit body comprises a pit main body excavated in the ground, first fender posts vertically penetrating into the pit main body along the ground and located at the peripheral side of the pit main body, two circles of second fender posts vertically penetrating into the ground along the peripheral side end of the pit main body, water stop piles vertically penetrating into the ground from the position between the two circles of second fender posts and a steel trestle built at the upper ends of the second fender posts and the water stop piles, and mounting bases for fixing the lower end of the steel trestle are arranged at the upper ends of the water stop piles and the second fender posts. The super high-rise building deep foundation pit and the construction method have the characteristics of convenience in foundation pit construction, convenience in steel trestle building and the like.

Owner:DARONG CONSTR GROUP

Construction method of a semi-fabricated cast-in-place concrete column

ActiveCN110206228BAvoid complex constructionEasy hoisting and positioningStrutsForms/shuttering/falseworksArchitectural engineeringSlurry

The invention discloses a construction method of a semi-fabricated cast-in-place concrete column. The construction method comprises the steps of 1, integrally and transversely fabricating a reinforcement cage and a steel formwork; 2, carrying out straight-anchorage positioning on a reinforcement cage and steel formwork integrated fabricated structure; 3, supporting the reinforcement cage and steelformwork integrated fabricated structure; 4, mounting a pouring platform; 5, removing integrated connection between the reinforcement cage and the steel formwork; 6, pouring the cast-in-place concrete column; and 7, dismantling the steel formwork. The reinforcement cage and the steel formwork are integrally and transversely fabricated, construction of the reinforcement cage and the steel formworkin a construction site is avoided, and high-altitude operation is avoided; meanwhile, overall hoisting and positioning of the reinforcement cage and the steel formwork are facilitated in the later stage; the pouring platform is arranged at the top end of the reinforcement cage and steel formwork integrated fabricated structure in a sleeving mode, so that the integrated connection between the reinforcement cage and the steel formwork is relieved conveniently, and the concrete pouring work of constructors is facilitated; formwork splicing joints are avoided, no slurry leaks, and the cast-in-place concrete column is poured and formed at a time without construction seams.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

An integral straight anchor positioning structure of reinforcement cage and steel formwork

ActiveCN110206305BEasy to liftAvoid complex constructionForms/shuttering/falseworksBuilding reinforcementsArchitectural engineeringRebar

The invention discloses an overall direct anchor positioning structure of a reinforcement cage and a steel formwork, which comprises a positioning foundation and an integrated structure of a reinforcement cage and a steel formwork. It includes a raft foundation and a steel formwork positioning frame arranged on a reserved opening in the raft foundation, and the reserved opening of the raft foundation is located directly above the reserved pit of the subsidence foundation of the reserved column. In the present invention, the first L-shaped steel formwork and the second L-shaped steel formwork are assembled to place the reinforcement cage in the steel formwork, and the reinforcement cage is placed in the steel formwork through the cooperation of the jacking bracket, the main reinforcement connecting pipe, the main reinforcement connecting sleeve and the main reinforcement fixing sleeve. It is fixed with the steel template as a whole, and the raft reinforcement positioning frame is used to locate the installation position of the raft reinforcement that passes through the reserved opening in the transverse direction, so as to avoid collision or obstruction of the raft reinforcement to the main reinforcement of the reinforcement cage in the later stage, and the steel template positioning frame is used for positioning. The position of the steel formwork in the connected steel cage and the steel formwork is optimized to simplify the construction process.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

Sloping roof fabricated slip form device

ActiveCN106884530AReduce in quantityImprove pouring qualityForms/shuttering/falseworksDevice formElectrical and Electronics engineering

The invention discloses a sloping roof fabricated slip form device which comprises standard sections, first and second end sections located at two ends of each standard section and guide rails arranged in the inclining direction of a sloping roof. The standard sections are detachably connected with the first end sections and the second end sections respectively, and a group of walking mechanisms are symmetrically installed on the outer sides of the first end sections and the outer sides of the second end sections and can walk along the guide rails and drive the whole device to move along the sloping roof. The first end sections, the standard sections and the second end sections respectively comprises bottom forms, cross rods, longitudinal rods and vertical rods, every two of the cross rods, the longitudinal rods and the vertical rods are connected, and the cross rods, the longitudinal rods and the vertical rods form a rectangular frame type structure and are fixed to the bottom forms. The sloping roof fabricated slip form device has the advantages that the whole sloping roof is caste in a multi-time mode, the width of each time of casting is equal to or slightly smaller than the width of the device during multiple times of casting, but the number of the devices can be decreased. The whole sloping roof can be also formed through one-time casting, although the number of the devices formed through one-time casting is small, the casting quality if good, and follow-up defect repairing work is avoided.

Owner:CHINA FIRST METALLURGICAL GROUP

Valve controllers and electric gates and electric valves

ActiveCN103256420BLimit loadAvoid damageOperating means/releasing devices for valvesElectric machineWhole body

Provided are a valve controller, an electric gate valve and an electric valve. The valve controller (10) comprises a motor (11); a power transmission unit (12) that transmits driving power of the motor to an external machine; a torque limiter (13) that makes the motor stop when the power transmission unit generates certain load during running of the motor; and a hand-operated handle (14) that applies power onto the external machine through the power transmission unit. The hand-operated handle has a rotatable body that is connected with the hand-operated handle to be a whole body to rotate; a torque drive part that is connected with the power transmission unit; and a friction generation part that enables friction to be generated between the rotatable body and the torque drive part. When torque applied by the hand-operated handle onto the rotatable body exceeds the friction between the rotatable body and the torque drive part, the torque drive part is separated from the power transmission unit and the rotatable body. Therefore, power of transmission to the external machine is limited via operation of the handle when load with the prescribed amount is generated.

Owner:WEST ELECTRIC CO LTD

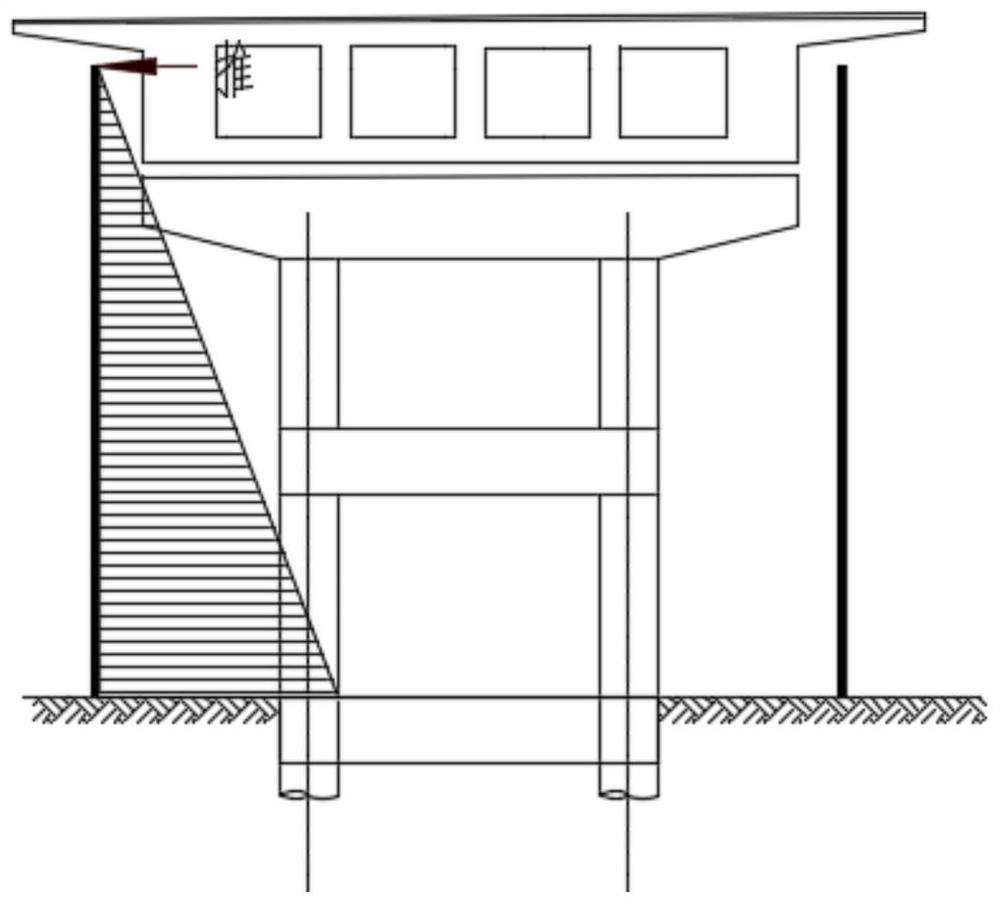

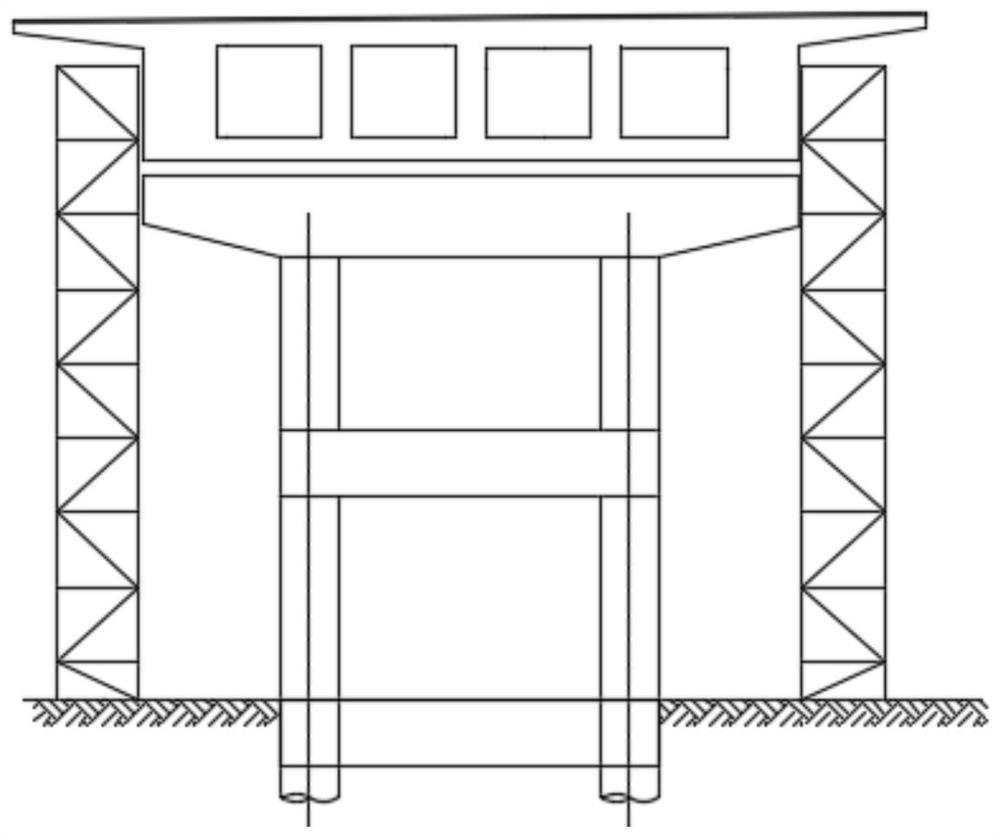

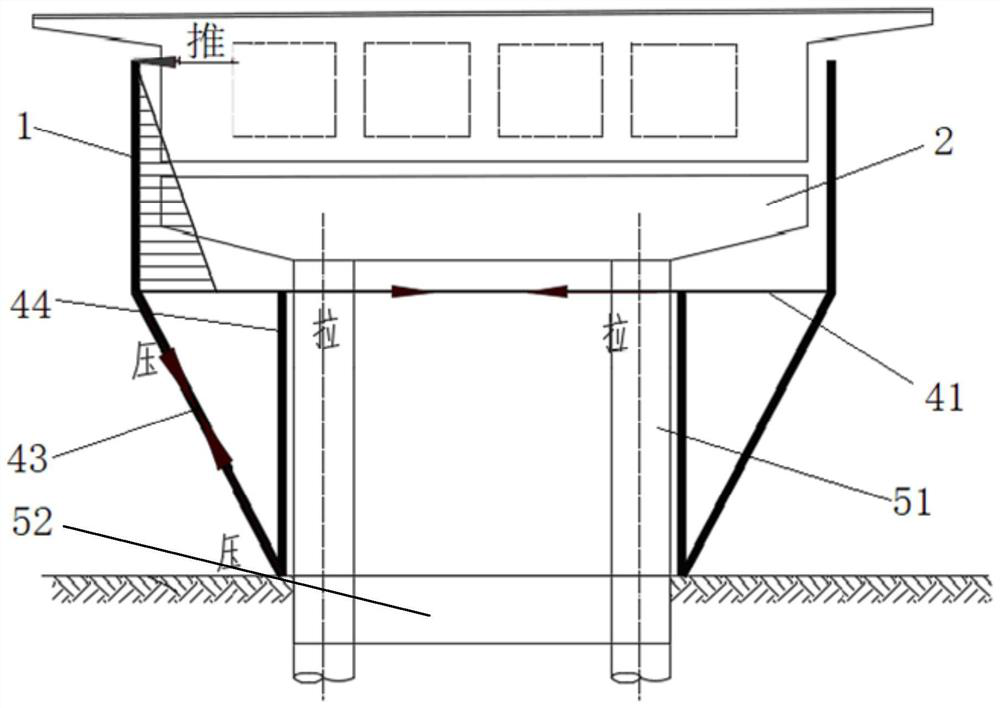

Bridge transverse limiting device based on tension and compression bar model and construction method

PendingCN114232466AGuaranteed construction periodAvoid complex constructionBridge structural detailsBridge erection/assemblyClassical mechanicsBar pressing

The invention discloses a bridge transverse limiting device based on a tension and compression bar model and a construction method. The device comprises a vertical supporting limiting piece (1), a horizontal tying piece (41) and an oblique compression supporting piece (43). The pair of vertical supporting limiting pieces (1) are arranged on the two sides of a bridge (2) respectively, the upper ends of the pair of inclined pressed supporting pieces (43) are fixedly connected with the lower ends of the pair of vertical supporting limiting pieces (1) respectively, and obtuse included angles are formed between the inclined pressed supporting pieces (43) and the vertical supporting limiting pieces (1). The lower ends of the pair of oblique compression supporting pieces (43) obliquely extend towards the lower part of the inner side respectively and are fixed on a pier structure of a bridge (2); and the horizontal tying piece (41) is horizontally tied between the connecting nodes of the pair of inclined pressed supporting pieces (43) and the pair of vertical supporting limiting pieces (1). Stable limiting can be provided on the two sides of the bridge, and the stability and safety of the bridge in the jacking process are ensured.

Owner:上海天演建筑物移位工程股份有限公司 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com