Structure of rapidly molded concrete cloth and laminating method

A technology of concrete cloth and concrete, which is applied in the fields of bridges, slope protection, road construction, and canals. It can solve the problems of manpower, material resources, time consumption, pollution, air and other environmental damage, and achieve project cost reduction, convenient use, and high construction quality. Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

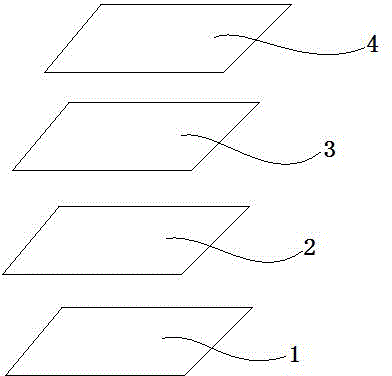

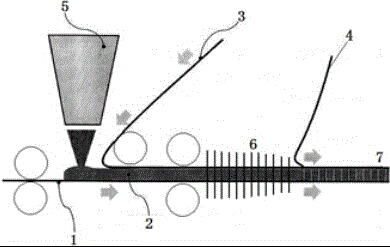

[0028] refer to figure 1 Shown, a kind of structure of rapid prototyping concrete cloth, this structure comprises concrete cloth base cloth layer 1 and nonwoven fabric layer 3, is provided with prefabricated cement concrete stem between described concrete cloth base cloth layer 1 and nonwoven fabric layer 3 The powder-mixed layer 2, the non-woven fabric layer 3 and the periphery of the concrete cloth base cloth layer 1 are compositely wound and bonded by needle-punching or stitching, and the outer surface of the non-woven fabric layer 3 is thermally melted and calendered or sprayed. The way of compounding is compounded with PVC / HDPE waterproof geomembrane layer 4 .

[0029] The concrete cloth base cloth layer 1 is composed of polypropylene staple fiber needle-punched non-woven fabric and polypropylene woven cloth.

[0030] The non-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com