Sloping roof fabricated slip form device

A sloping roof and prefabricated technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of difficult concrete quality, unsatisfactory concrete effect, and heavy repair workload, etc. , to achieve the effect of eliminating defect repair work, saving production costs and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

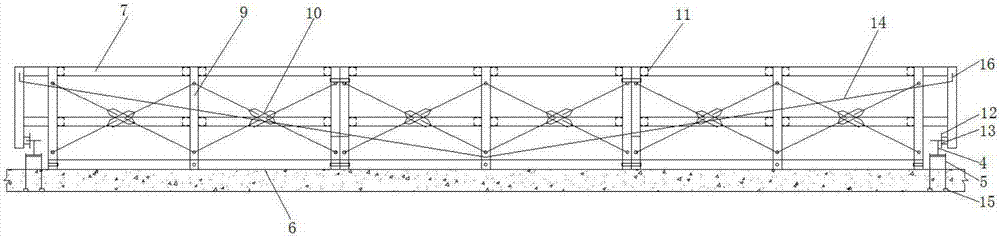

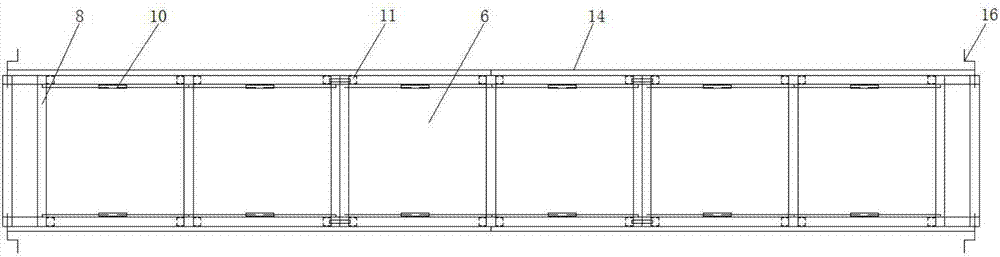

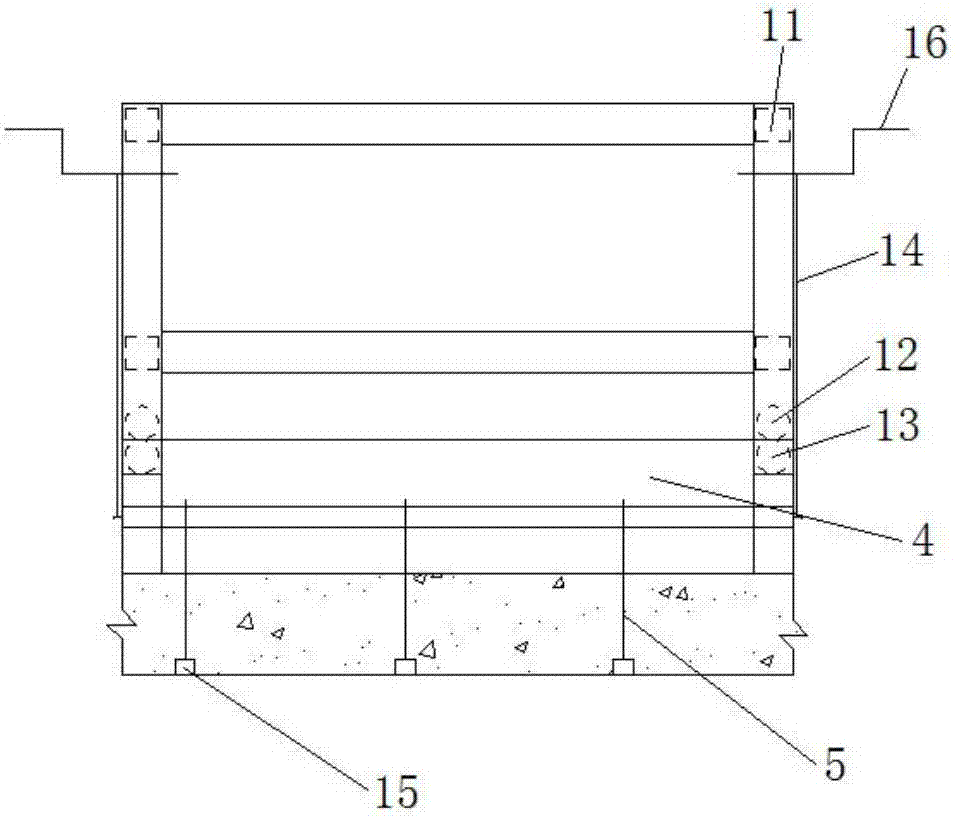

[0025] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as figure 1 The assembled sliding form device for a sloping roof includes a standard section 1, a first end section 2 and a second end section 3 located at both ends of the standard section 1, and guide rails 5 arranged along the slope direction of the sloping roof; The standard section 1 is detachably connected with the first end section 2 and the second end section 3 respectively; a set of traveling mechanisms are installed symmetrically on the outside of the first end section 2 and the second end section 3, and the traveling mechanism can walk along the guide rail 5, Drive the whole device to move along the slope roof.

[0027] Preferably, the structures of the first end section 2, the standard section 1 and the second end section 3 are basically the same, and the lengths are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com