Fabricated foam concrete outer wall insulation board, structure thereof and mounting method of fabricated foam concrete outer wall insulation board

A technology of foam concrete and external wall insulation boards, applied in insulation, building structure, building components, etc., can solve the problems of difficult construction quality assurance, hidden strength and safety hazards, complex construction technology, etc., and achieve low construction period and construction cost , avoid the effect of complex construction and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to fully explain the implementation of the present invention, the implementation examples of the present invention are provided below, and these implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

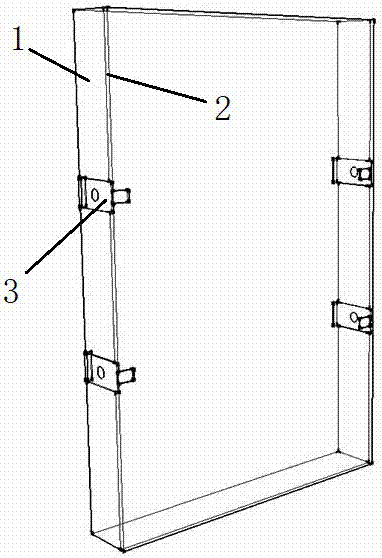

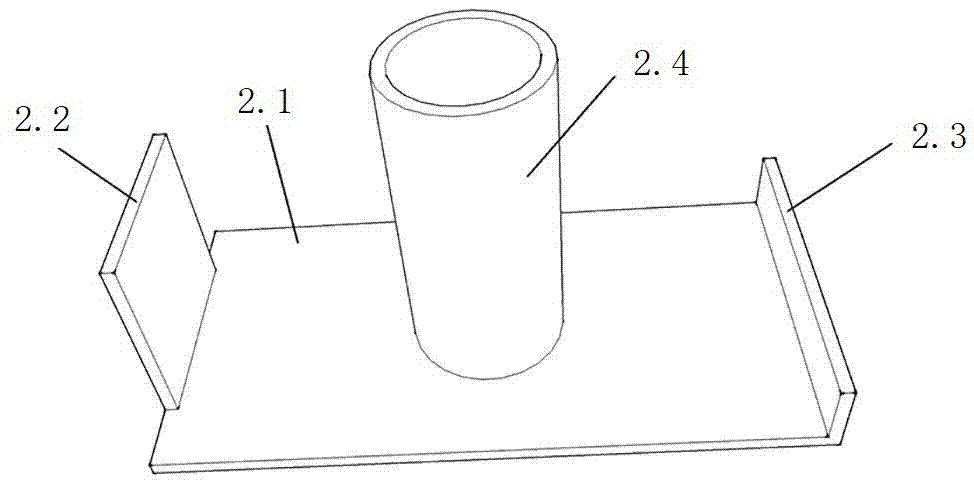

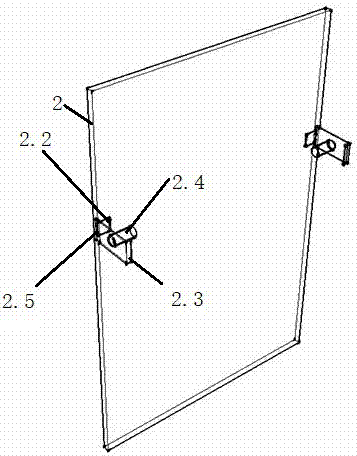

[0025] A further detailed explanation of the present invention is given in conjunction with the accompanying drawings, which are marked as: 1. Foam concrete insulation layer; 2. Finishing layer; 3. External parts; 2.1. ;2.4. Sleeve; 2.5. Clamping groove; 3.1. Metal mesh; 4.1. Connector bottom plate; 4.2. Connecting rod A; 4.3. Connecting rod B; 4.4. Long hole; 5.1. Mounting hole; 5.2. ;6.1. Wall hanging parts; 6.2. Connectors; 8.1. Prefabricated foam concrete exterior wall insulation board; 8.2. Exterior wall body; 8.3. Foam concrete filling layer; Corner; 9.4. Top seal plate; 9.5. Top seal finish layer; 9.6. Opening plate; 9.7. Opening finish layer; 9.8. External corner plate; 11.1. layer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com