Large-span stiff beam screw-free structure and construction method thereof

A construction method and technology for stiff beams, which are applied to structural elements, elongated structural components for load-bearing, building components, etc., can solve problems such as unsuitability of large-section steel beams, difficulty in setting pull screws, and wasteful construction. , to avoid complicated construction, improve construction efficiency, enhance bending resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

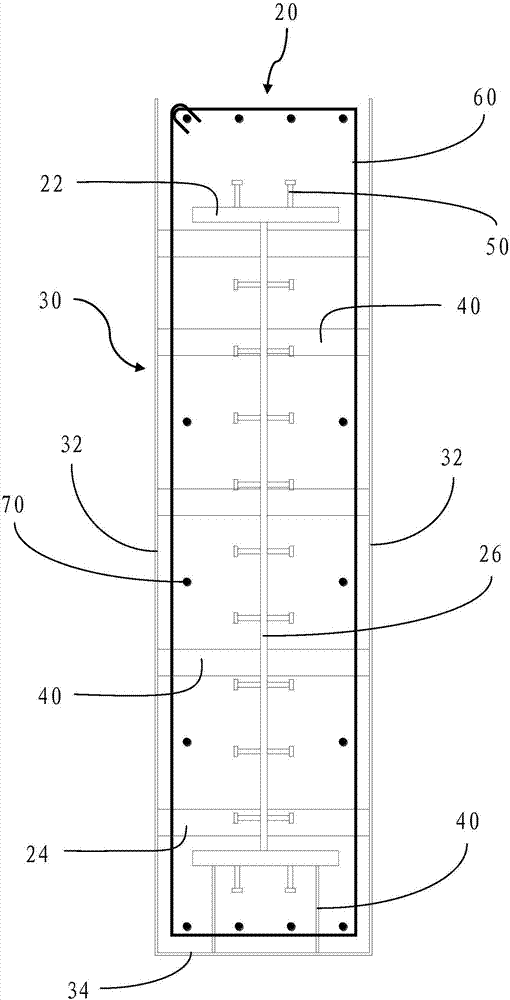

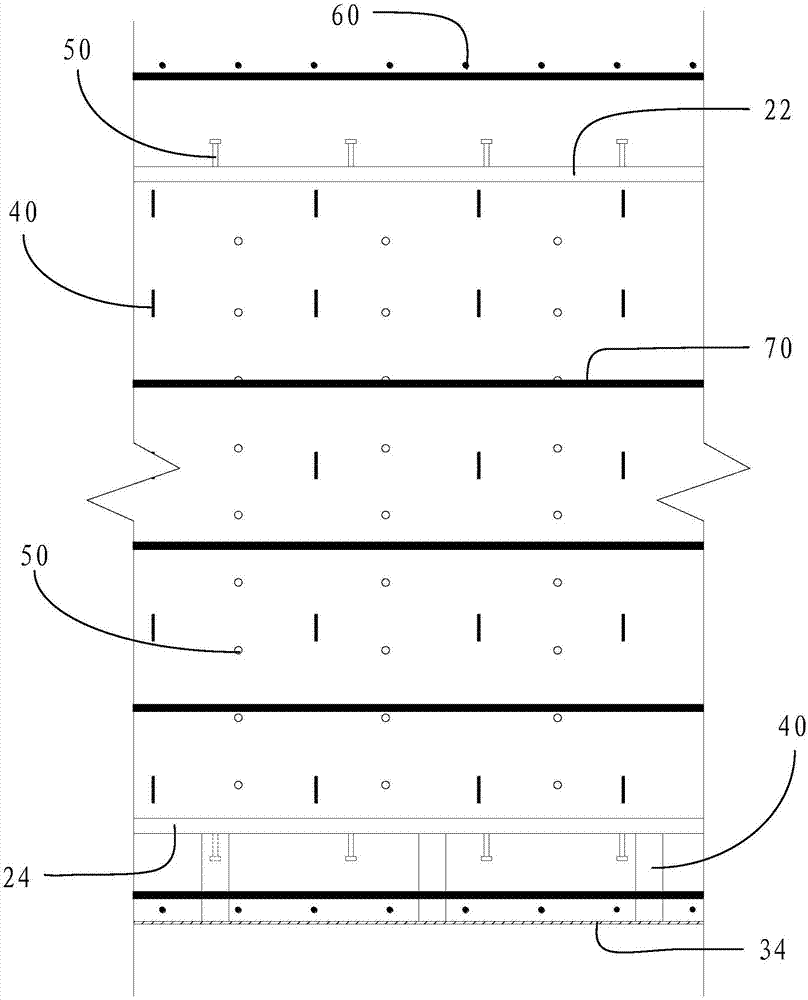

[0028] Such as figure 1 and figure 2 As shown, the screw-free structure of the large-span stiff beam of the present invention includes a beam steel frame 20, a beam frame 30, and a connecting plate 40. The beam frame 30 is U-shaped and is composed of two side plates 32 and a bottom plate 34. , the beam steel frame 20 is located in the beam frame 30, and connecting plates 40 are respectively fixed between the beam steel frame 20 and the two side plates 32 of the beam frame 30, and the beam steel frame A connecting plate 40 is also fixed between the bottom of the frame 20 and the bottom plate 34 of the beam outer frame 30 , so that the beam steel frame 20 is fixedly connected in the beam outer frame 30 through the connecting plate 40 .

[0029] Further, the beam steel frame 20 is composed of a plurality of I-beam ends connected in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com