Switching operating device and object cutting method

A technology of opening and closing action and object, which is applied in the direction of metal processing, etc., can solve the problems that the pneumatic clamp cannot directly clamp the cut part, increase the amount of discarded wires, increase the cutting process, etc., and achieve compactness of the device, easy assembly, The effect of preventing the complication of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

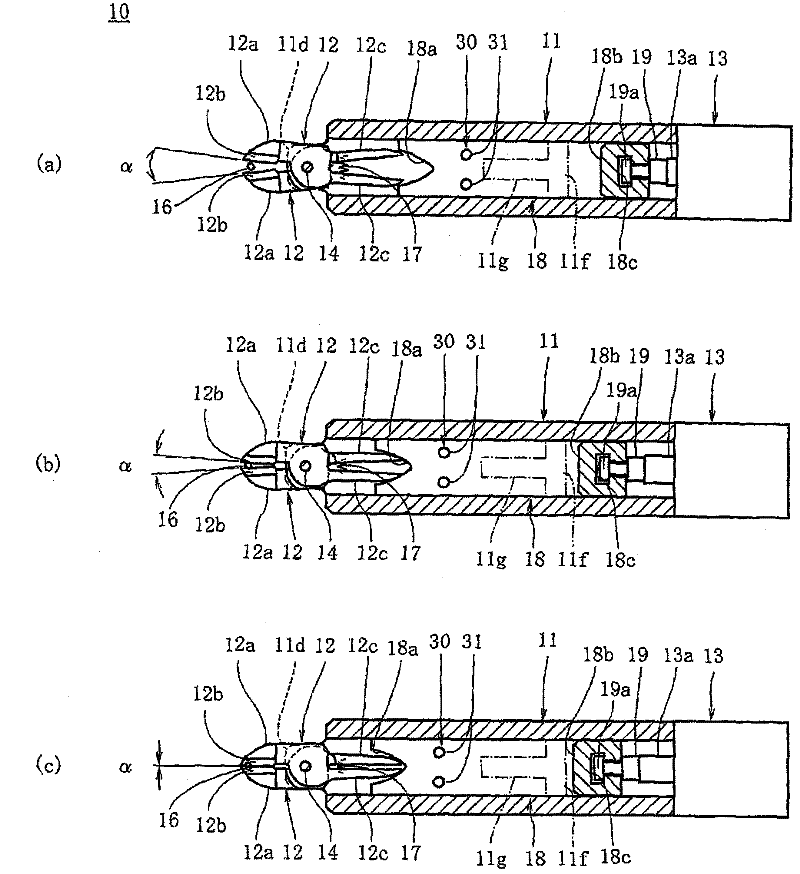

[0020] Hereinafter, the best mode for carrying out the present invention will be described based on the drawings.

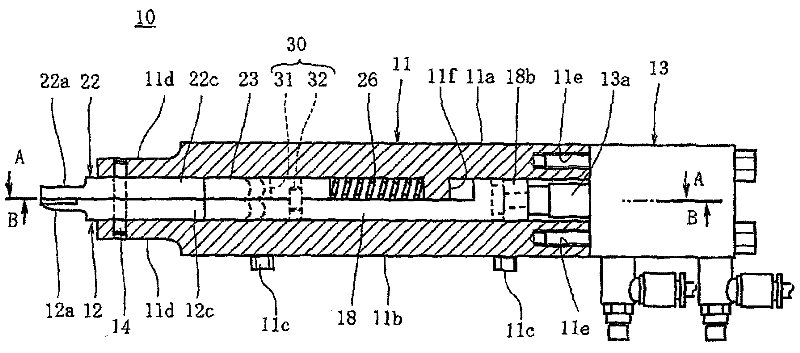

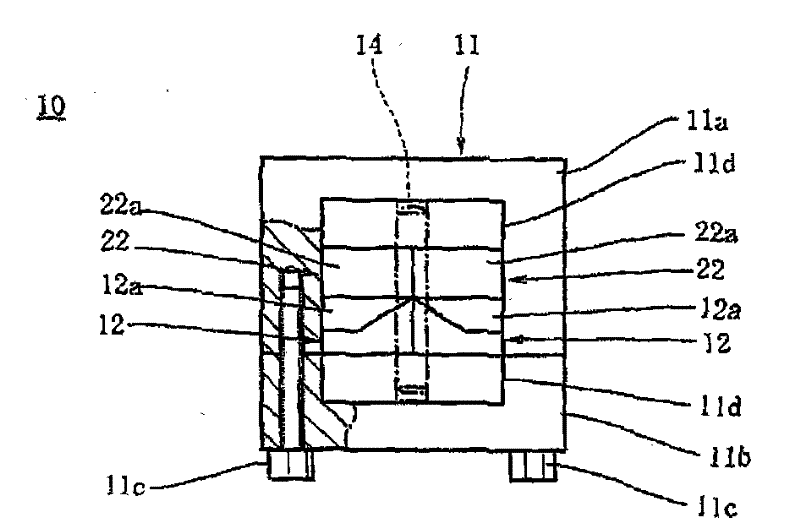

[0021] figure 1 The opening and closing operation device 10 of the present invention is shown in . The opening and closing operation device 10 includes a cylindrical body 11 and a pair of cutting rods 12 pivotally supported on the front end of the body 11 . Such as figure 2 As shown, the body 11 is formed into a square tube shape by attaching the second body part 11b to the U-shaped opening of the first body part 11a having a U-shaped cross section with small screws 11c. The second body part 11b blocks the opening of the first body part 11a.

[0022] Such as figure 1 and figure 2 As shown, at the front end of the fuselage 11, a pair of shaft support portions 11d, 11d, which are parallel to each other at a predetermined interval, protrude forward in order to sandwich a pair of cutting rods 12, 12 from both sides and perform shaft support. formed. In addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com