Reinforcement cage and steel formwork integrated transverse fabrication structure

A technology for assembling structures and steel formwork, which is applied in the direction of structural elements, formwork/formwork/work frames, building components, etc., can solve the problems of inapplicability, achieve strong applicability, reduce peripheral volume, and have good use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

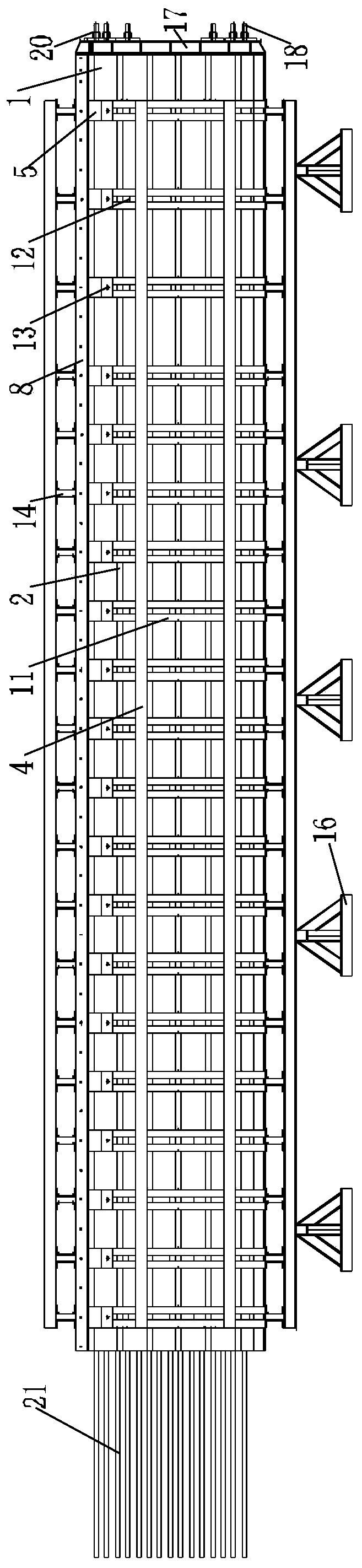

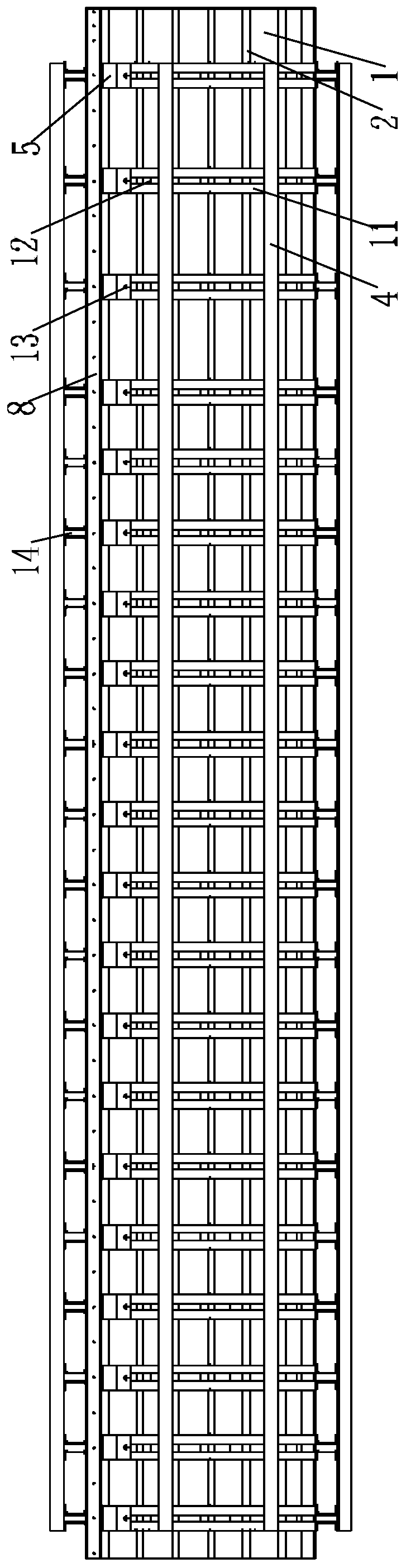

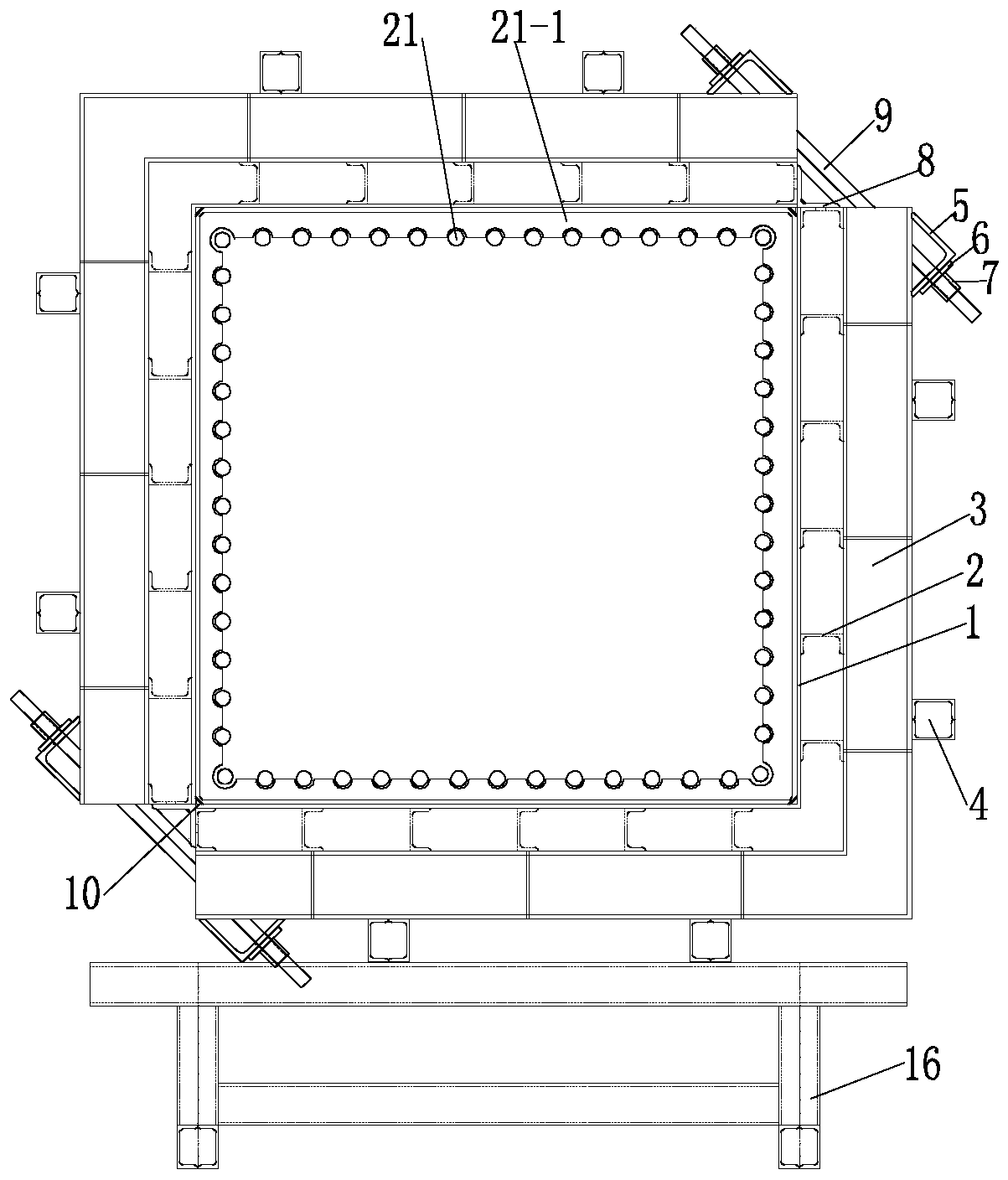

[0043] Such as Figure 1 to Figure 9 As shown, the present invention includes an assembly platform for laterally supporting the steel formwork and a jacking 17 matched with the steel formwork, a reinforcement cage 21 is placed in the steel formwork, and the reserved end of the reinforcement cage 21 protrudes to the Outside the steel formwork, the end of the steel formwork away from the reserved end of the bottom of the steel cage 21 is the top of the steel formwork, and the top of the steel formwork is fixedly connected to the jacking 17 through the steel formwork top seal plate 22, and the steel formwork The formwork includes a first L-shaped steel support formwork and a second L-shaped steel support formwork matched with the first L-shaped steel support formwork, and the first L-shaped steel support formwork and the second L-shaped steel support formwork The structural dimensions are all the same, and the first L-shaped steel formwork includes an L-shaped steel panel 1, a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com