Steel formwork and manufacturing method thereof

A technology of steel formwork and supporting formwork, which is applied in the field of steel formwork and its production, can solve the problems of low construction efficiency, low degree of mechanization, and large labor demand, and achieve the effects of avoiding complex construction, strong applicability, and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

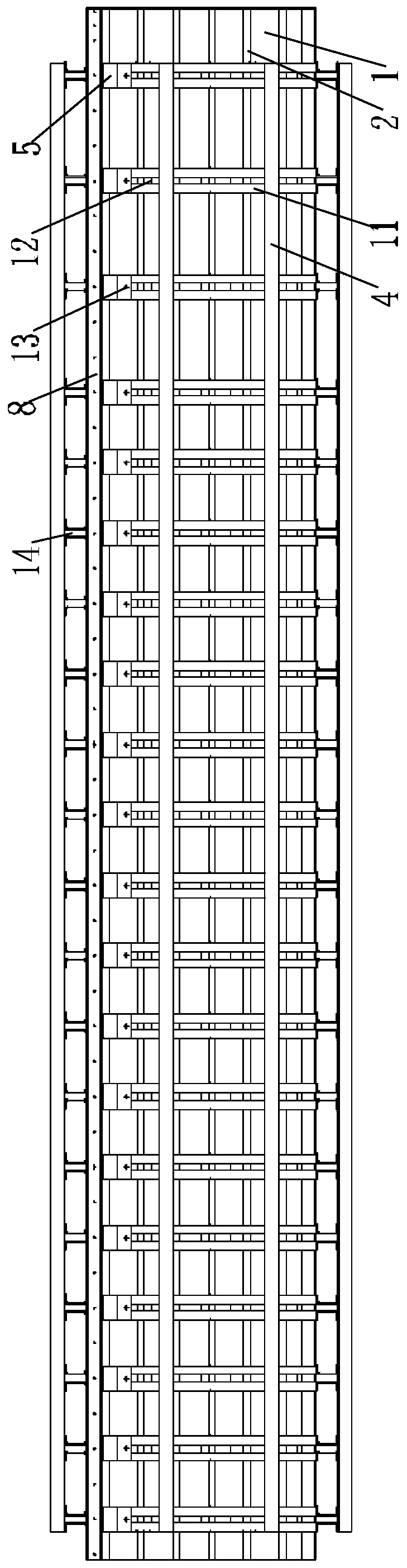

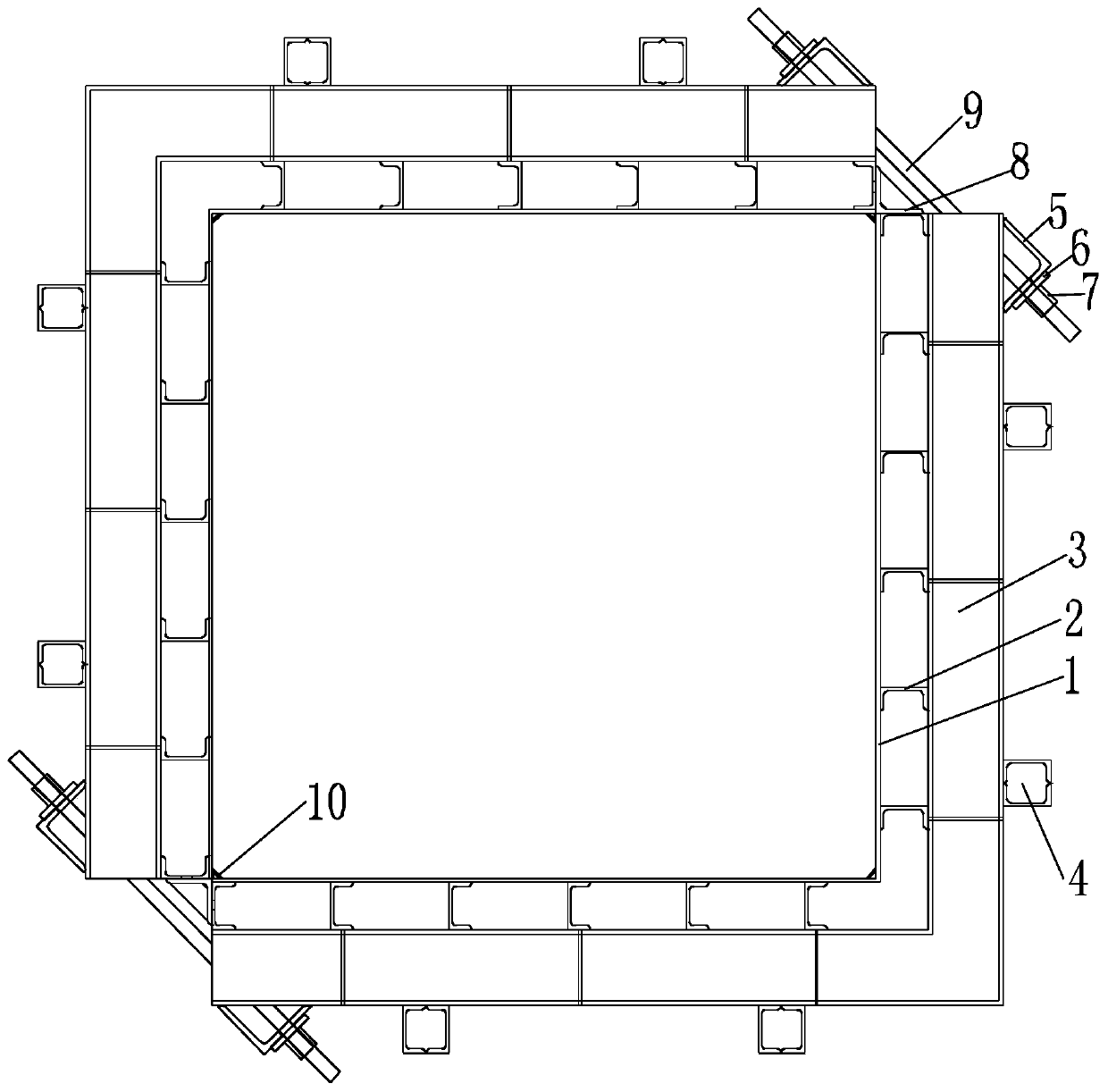

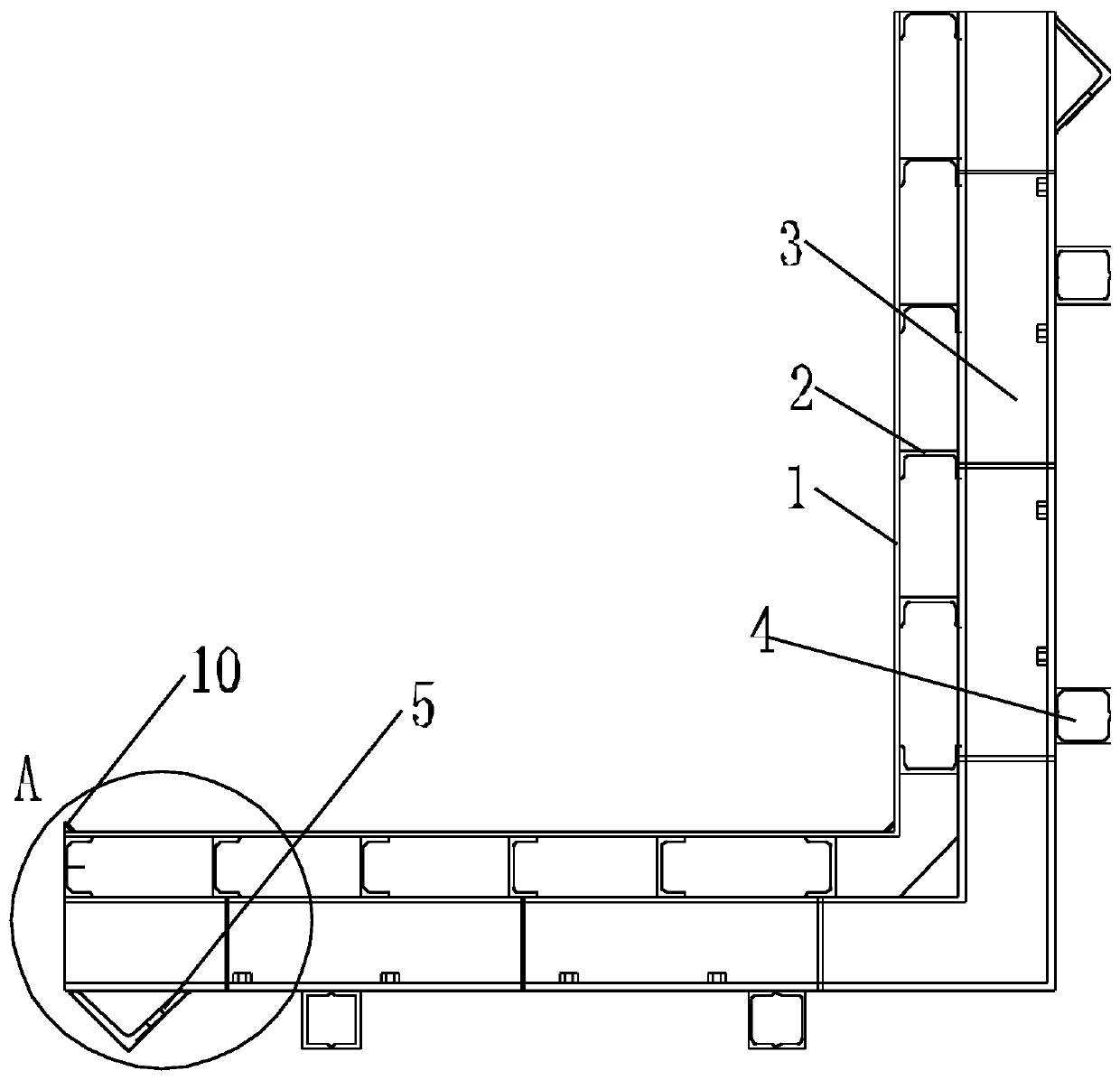

[0048] Such as Figure 1 to Figure 4 As shown, a steel formwork according to the present invention includes a first L-shaped steel support formwork and a second L-shaped steel support formwork matched with the first L-shaped steel support formwork, and the first L-shaped steel support formwork The structural dimensions of the formwork and the second L-shaped steel formwork are the same, and the first L-shaped steel formwork includes an L-shaped steel panel 1, a secondary reinforcement layer fixed on the outer surface of the L-shaped steel panel 1, fixed on the The main reinforcement layer on the outside of the secondary reinforcement layer and the reinforcement layer fixed on the outside of the main reinforcement layer, the secondary reinforcement layer includes a plurality of secondary reinforcements 2 fixed on the outer surface of the L-shaped steel panel 1 in parallel and arranged vertically, The main rib layer includes a plurality of L-shaped main ribs 3 arranged along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com