Rebar cage and steel formwork integral direct anchoring positioning structure

A technology for positioning structures and steel formwork, applied to structural elements, formwork/formwork/work frames, building components, etc., can solve problems such as inapplicability, and achieve the effect of simple use, easy promotion and use, and easy overall hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

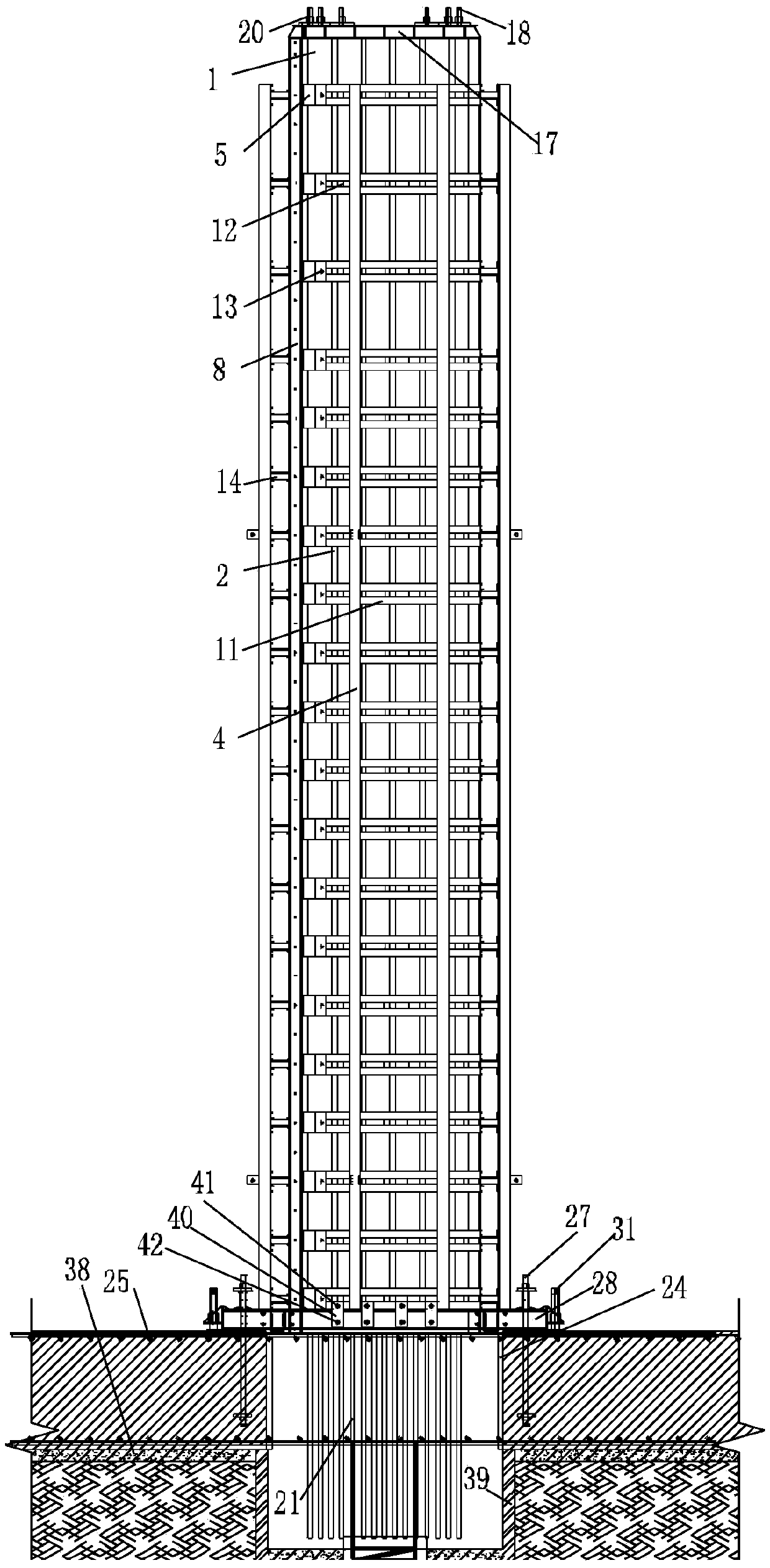

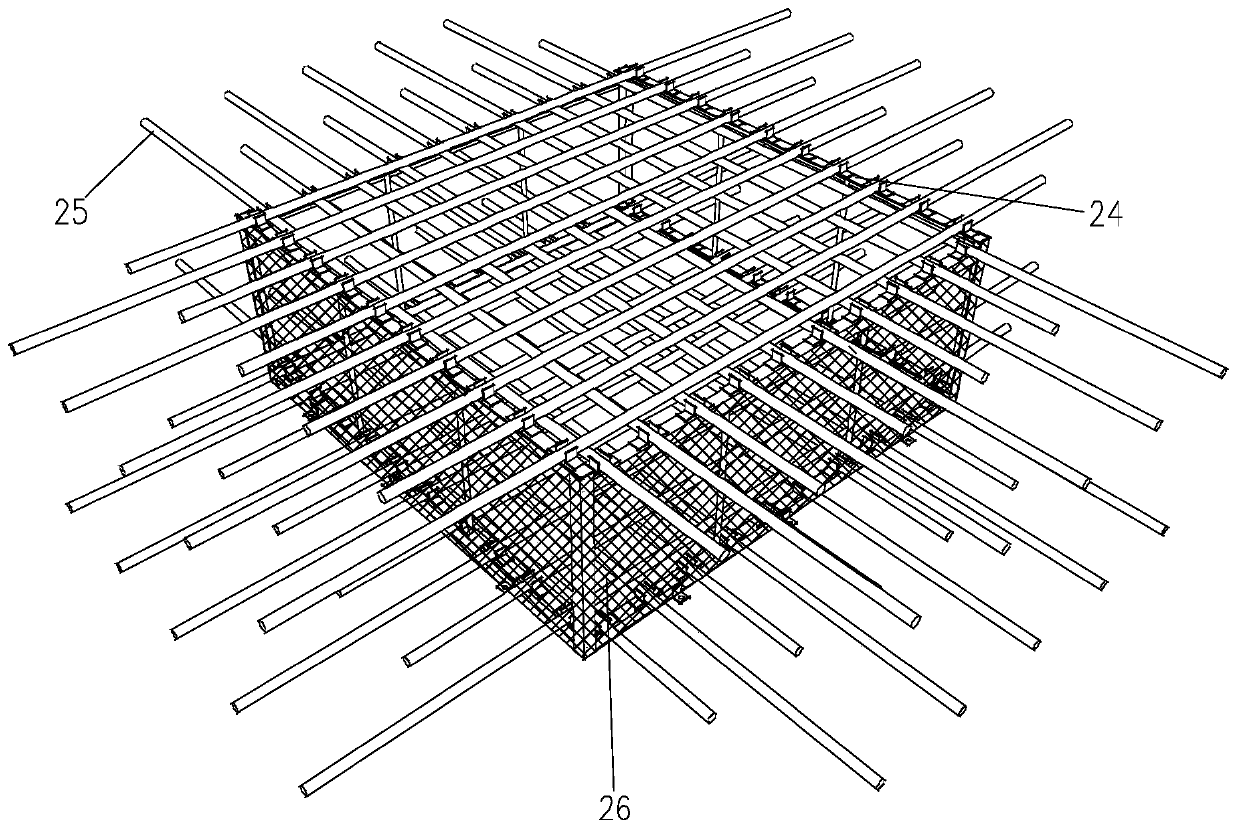

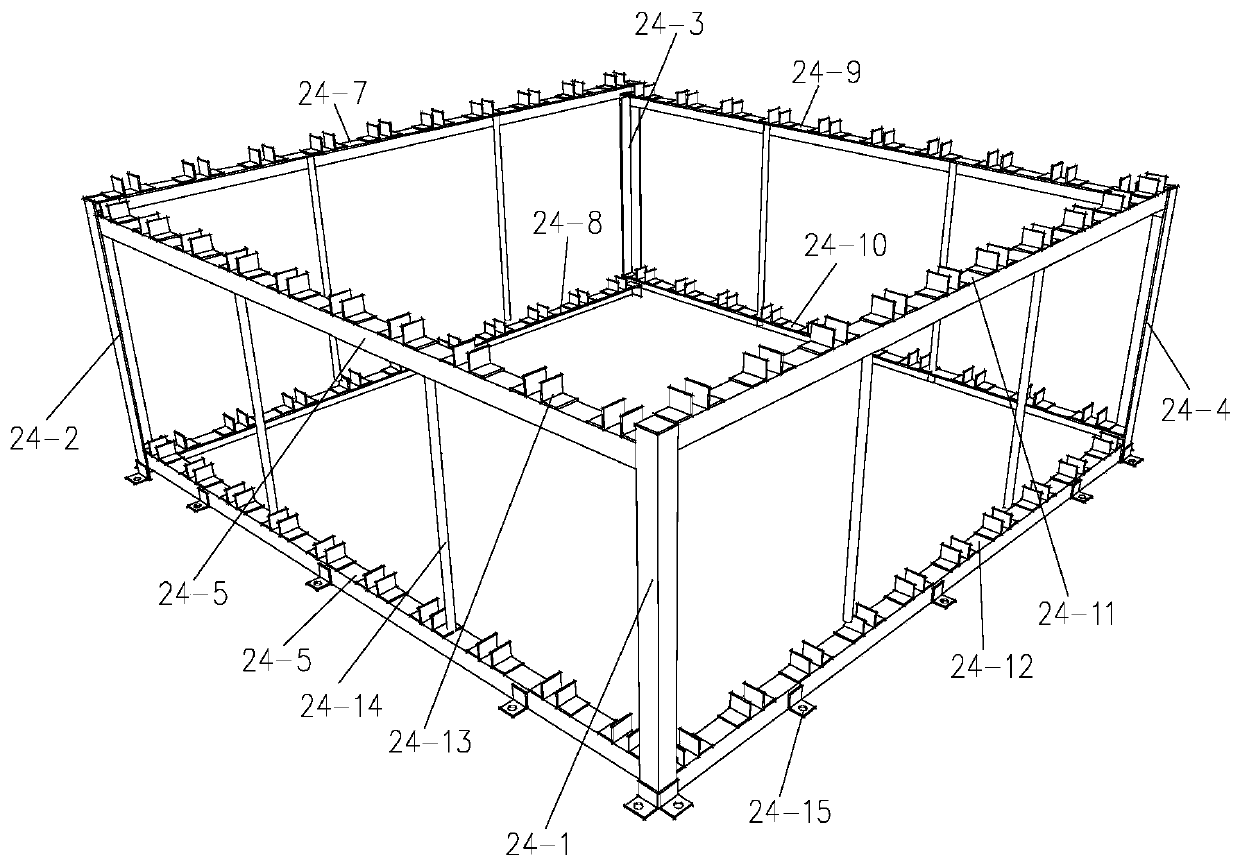

[0061] Such as Figure 1 to Figure 11As shown, the present invention includes an integrated structure of a reinforcement cage and a steel formwork and a positioning foundation that cooperates with the integrated structure of a reinforcement cage and a steel formwork, and the integrated structure of a reinforcement cage and a steel formwork is directly anchored with the positioning foundation through a hoist , the positioning foundation includes a raft foundation arranged on the reserved column sinking foundation 39 and a reserved opening and a steel formwork positioning frame arranged on the reserved opening, and the reserved column sinking foundation 39 and the raft foundation A cushion layer 38 is laid between them, and a cushion layer reserved opening is reserved on the cushion layer 38. The reserved opening of the raft foundation is located directly above the reserved pit of the reserved column sinking foundation 39, and the raft foundation The reserved opening of the rese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com