Super high-rise building deep foundation pit and construction method thereof

A deep foundation pit and super high-rise technology, applied in the field of infrastructure construction, can solve problems such as troublesome construction of steel trestles and instability of steel trestles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

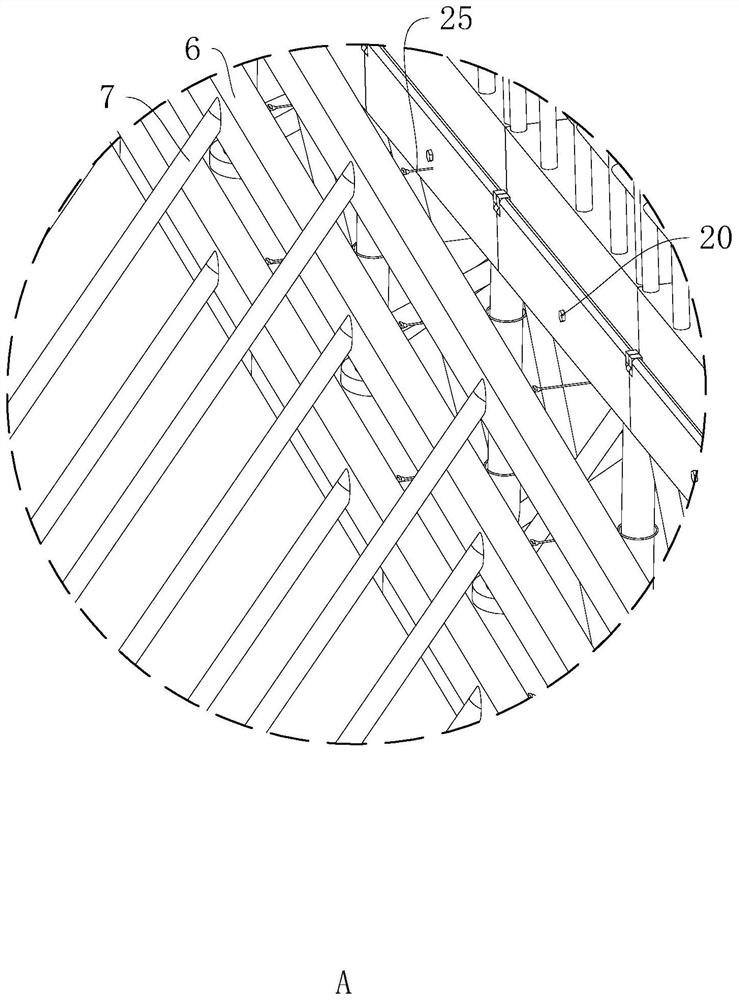

[0039] The following is attached Figure 1-6 The application is described in further detail.

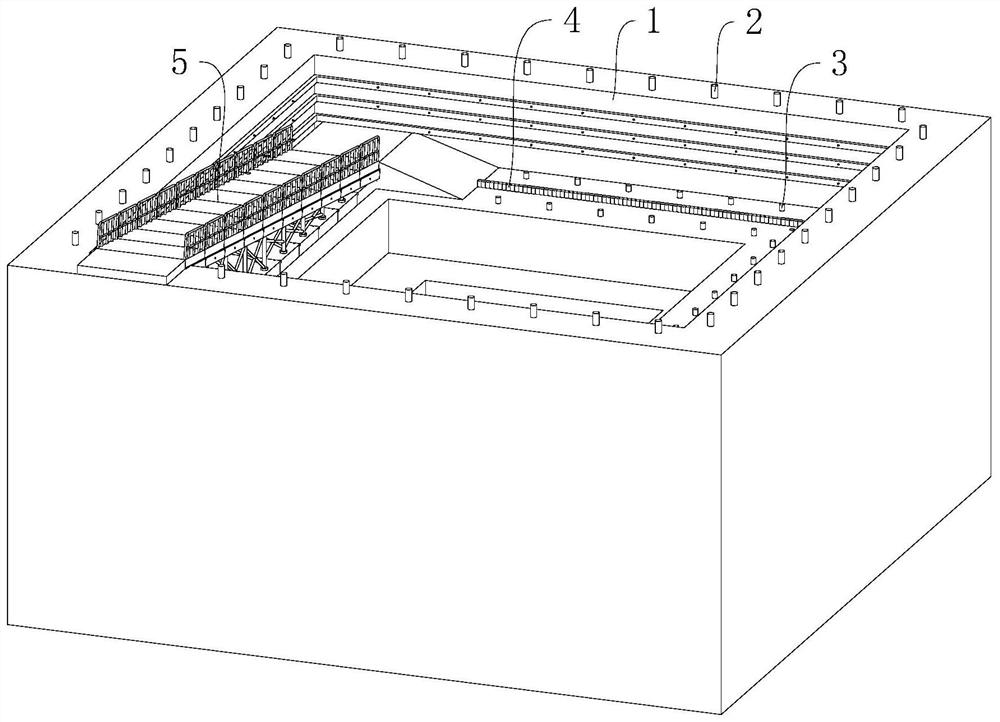

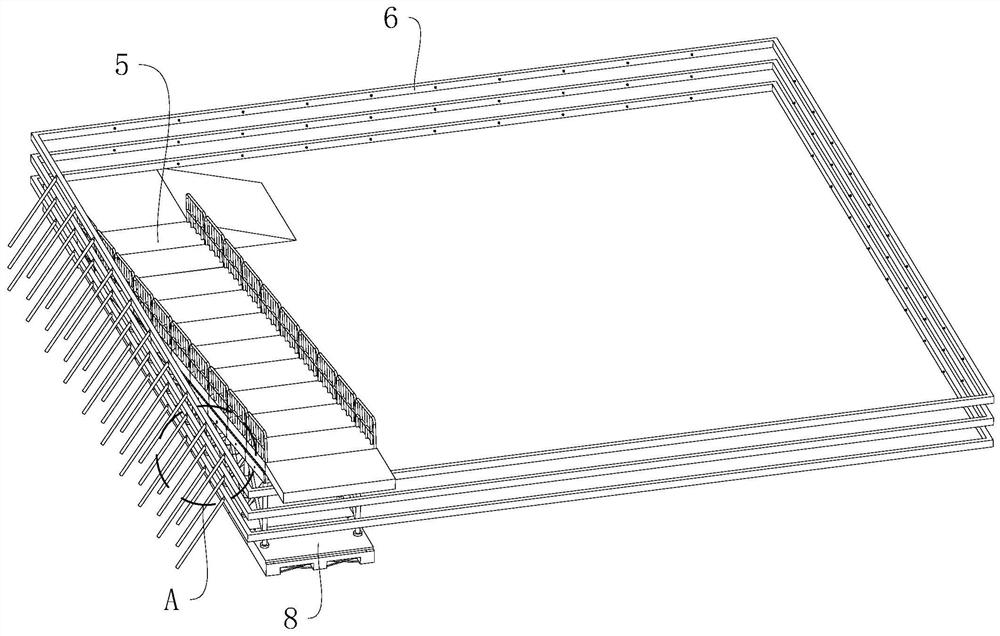

[0040] see figure 1 , a deep foundation pit for a super high-rise building, comprising a foundation pit body, the foundation pit body comprising a pit body 1 excavated on the ground, a first surrounding protection pile 2, a second surrounding protection pile 3, a water stop pile 4 and built on the ground The steel trestle 5 in the pit body 1.

[0041] The pit body 1 is a square deep pit, the side length of the pit body 1 is 40 meters, and the depth is 10 meters. The first enclosure pile 2 is a cylindrical concrete pouring pile. The diameter of the first enclosure pile 2 is 30 cm, the length 20 meters, a pouring hole with a depth of 20 meters is drilled vertically outside the pit body 1, and the steel cage is sunk into the pouring hole and then poured to form the first enclosure pile 2, and each first enclosure pile 2 to the outside of the pit body 1 and the distance between adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com