Integrated horizontal assembly method of reinforcement cage and steel formwork

An assembly method and steel formwork technology, applied in the fields of formwork/formwork/work frame, preparation of building components on site, processing of building materials, etc., can solve problems such as inapplicability, and achieve flexible use, strong adaptability, and occupation The effect of a large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

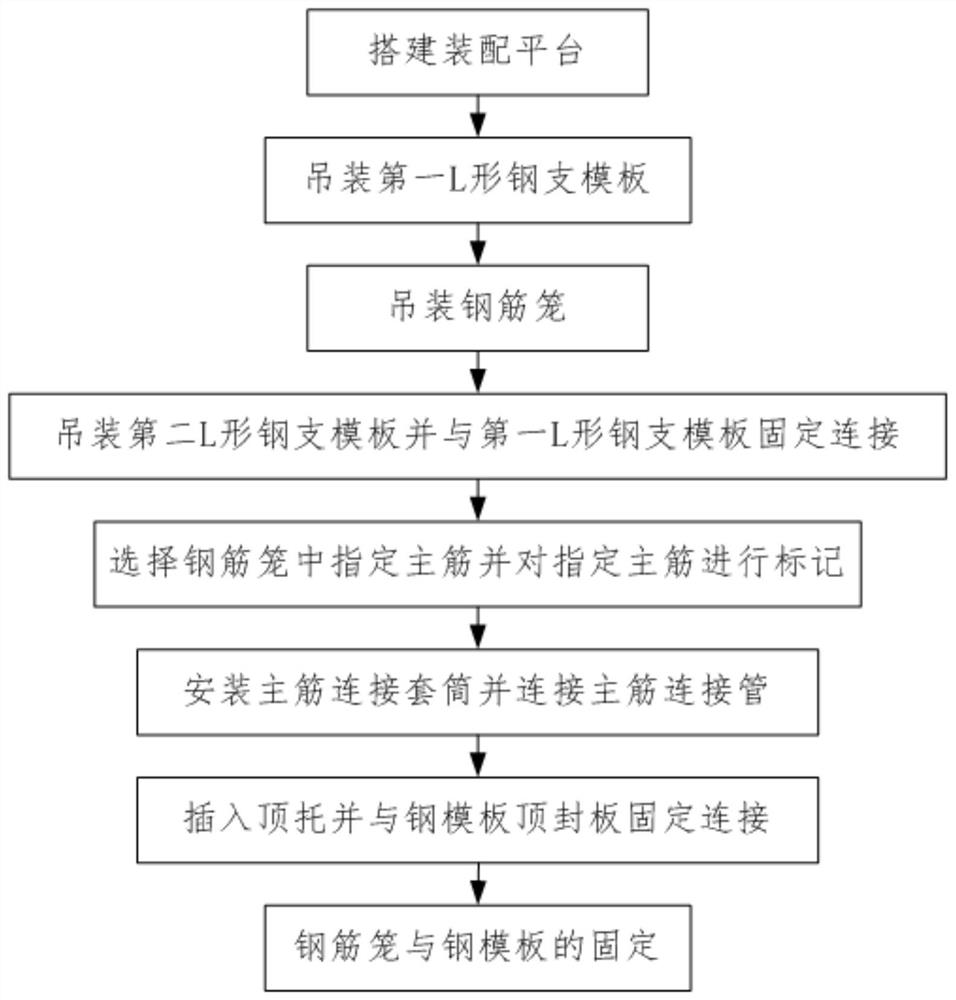

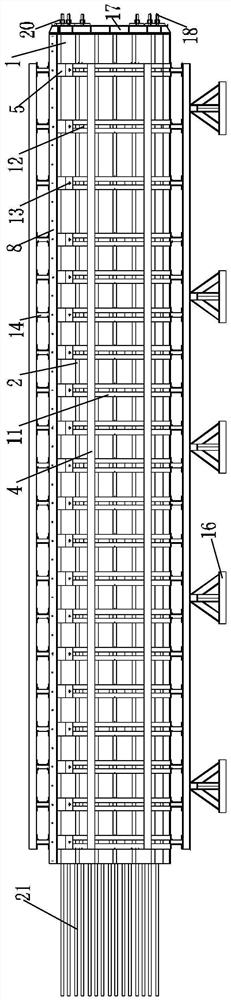

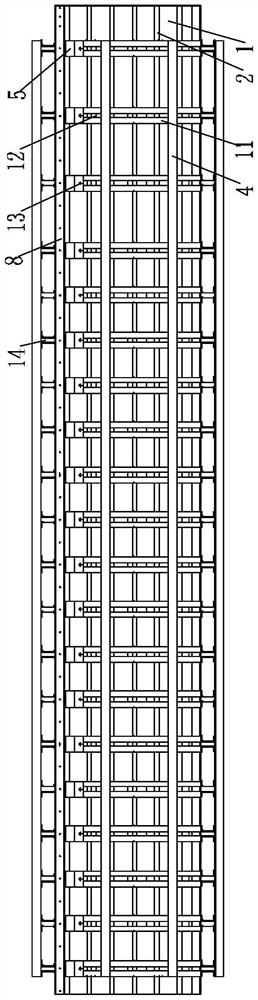

[0055] like Figure 1 to Figure 10 As shown in the present invention, the integrated horizontal assembly method of the reinforcement cage and the steel formwork, the steel formwork comprises a first L-shaped steel support formwork and a second L-shaped steel support formwork matched with the first L-shaped steel support formwork, so The structural dimensions of the first L-shaped steel support formwork and the second L-shaped steel support formwork are the same, and the first L-shaped steel support formwork includes an L-shaped steel panel 1, which is fixed on the outer surface of the L-shaped steel panel 1. The secondary rib layer, the main rib layer fixed on the outer side of the secondary rib layer, and the reinforcement layer fixed on the outer side of the main rib layer, the secondary rib layer includes a plurality of parallel fixed on the outer surface of the L-shaped steel panel 1 and vertical The length of the secondary rib 2 is equal to the height of the L-shaped stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com