Automatic fire extinguishing system for belt conveyor based on distributed optical fiber temperature measurement technology

An automatic fire extinguishing system and belt conveyor technology, applied in fire prevention, safety devices, mining devices, etc., can solve the problems that the deployment and control range is limited to local key areas, can not achieve targeted fire extinguishing, and monitor the location of the fire source is not specific, etc., to achieve Fast, timely and effective fire extinguishing effect, low cost of fire extinguishing, and wide coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described below.

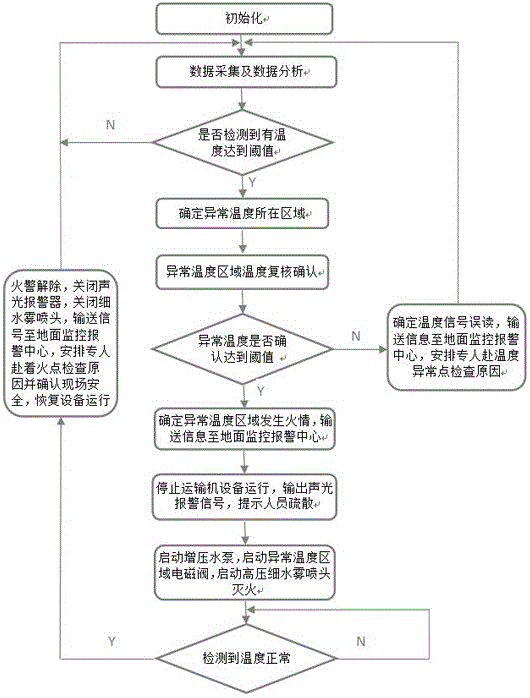

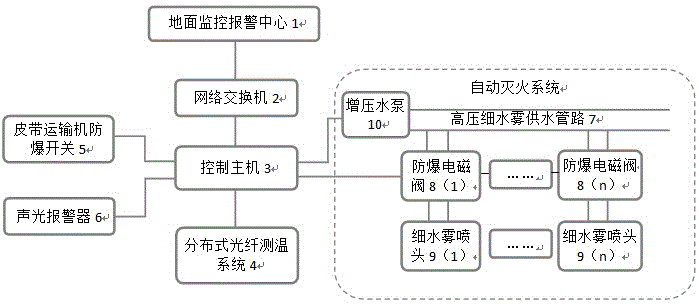

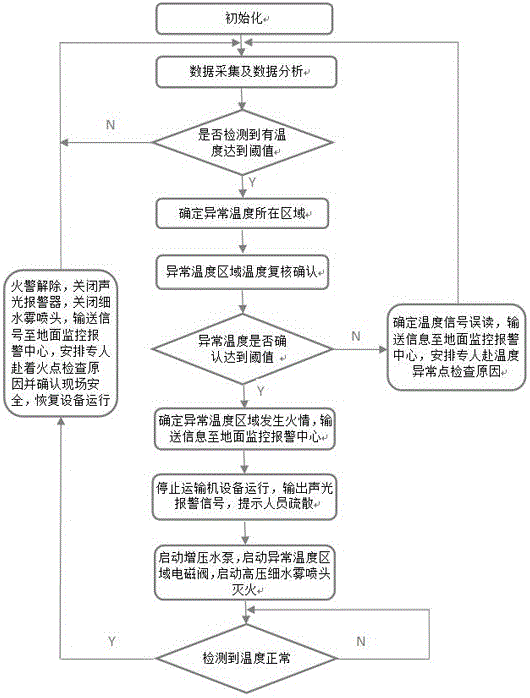

[0022] as attached figure 1 As shown, the belt conveyor automatic fire extinguishing system based on distributed optical fiber temperature measurement technology of the present invention includes ground monitoring and alarm center 1, network switch 2, downhole control host 3, distributed optical fiber temperature measurement system 4, belt conveyor explosion-proof switch 5, Sound and light alarm 6 and automatic fire extinguishing system. Ground monitoring and alarm center 1 is composed of computer host, sound and light alarm, large-screen display, mouse and keyboard; 3 are connected; the distributed optical fiber temperature measurement system 4 is composed of a distributed optical fiber temperature measurement host 4 (1) and a temperature sensing optical cable 4 (2), and the distributed optical fiber temperature measurement host 4 (1) is connected to the temperature sensing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com