Sectional sliding roof steel truss assembling method

A steel truss and sliding technology, which is applied in segmental assembly, segmental sliding roof steel truss and assembly, and sliding construction fields, can solve the problems of short skylight period, long interval time, and difficult construction organization, and achieve welding The quality is guaranteed, the construction organization is convenient, and the effect of avoiding high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention The construction technical requirements such as Chinese steel pipe lofting, welding, hoisting, etc. will not be repeated, and the embodiments of the present invention will be emphasized. The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. This description is not limited to the following Example.

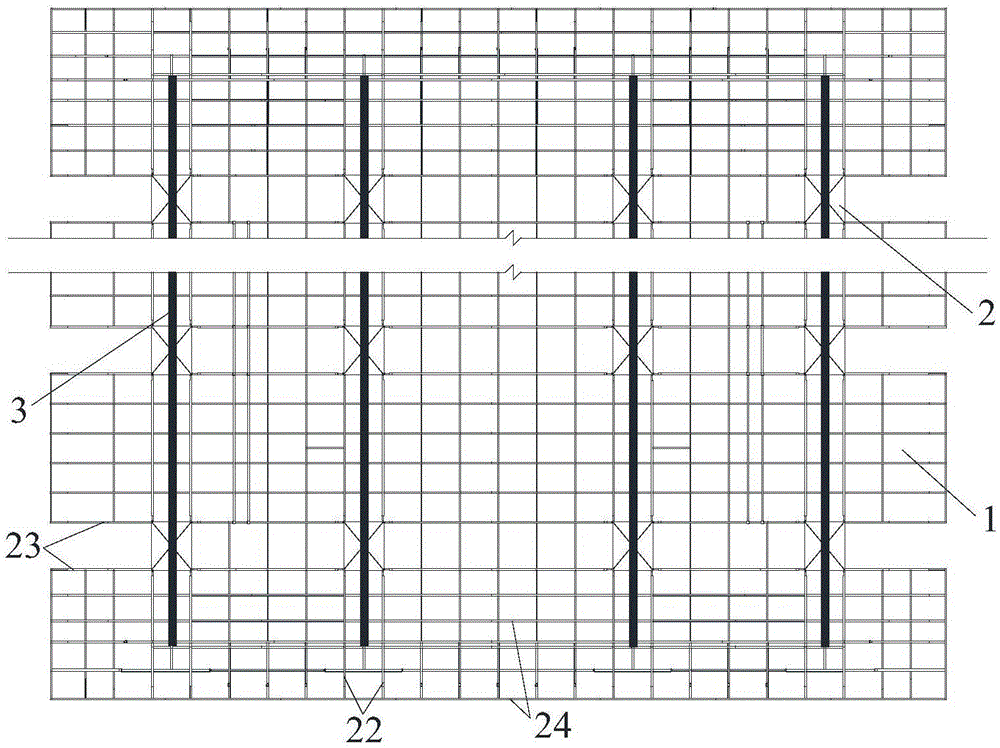

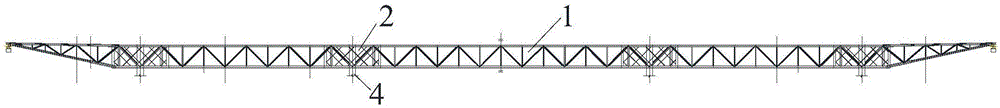

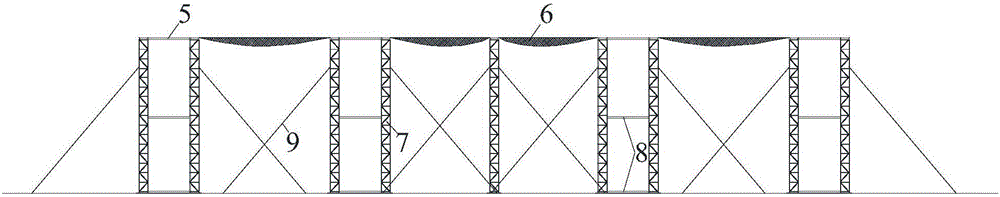

[0037] figure 1 It is the layout plan of roof steel truss, figure 2 is the longitudinal section of the roof steel truss, image 3 is the construction platform layout drawing, Figure 4 is the support truss structure diagram, Figure 5 is the slippery device, Figure 6 It is a structure diagram of a slipper shoe, Figure 7 is the location diagram of the segmented steel truss, Figure 8 It is a segmented steel truss support structure, Figure 9 yes Figure 6 For detailed diagram of node A in middle, refer to Figure 1-9 shown.

[0038] The roof steel truss is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com