Preparation method for preformed hole split pouring fender pile

A technology of retaining piles and reserved holes, which is applied to sheet pile walls, manufacturing tools, lubricating compositions, etc., can solve the problems of unsuitable deep base projects, high project cost, and complicated construction, and achieve convenient construction organization and smooth construction. The effect of short cycle time and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

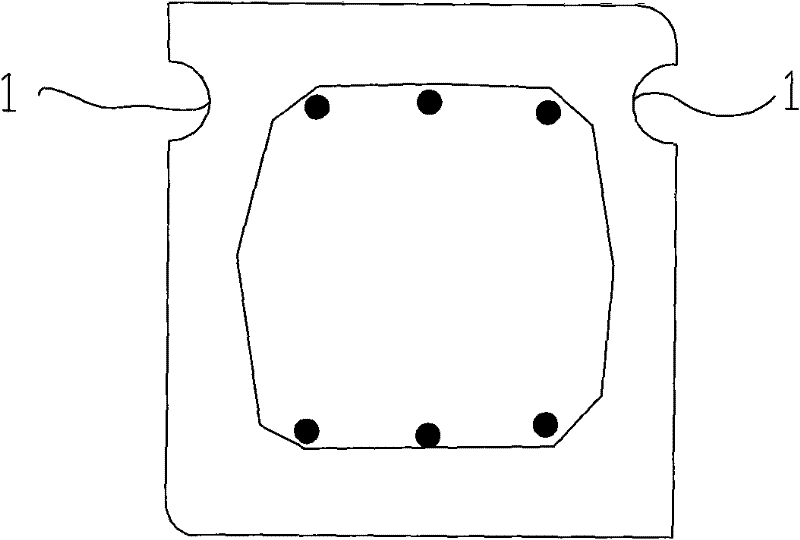

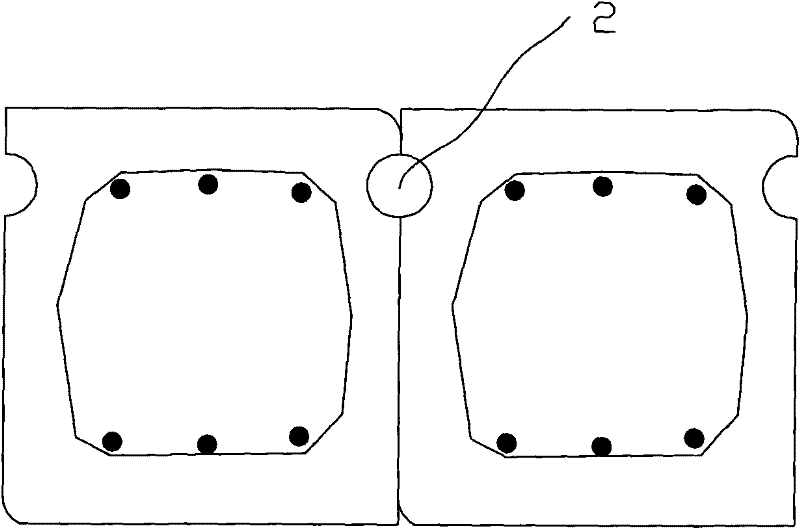

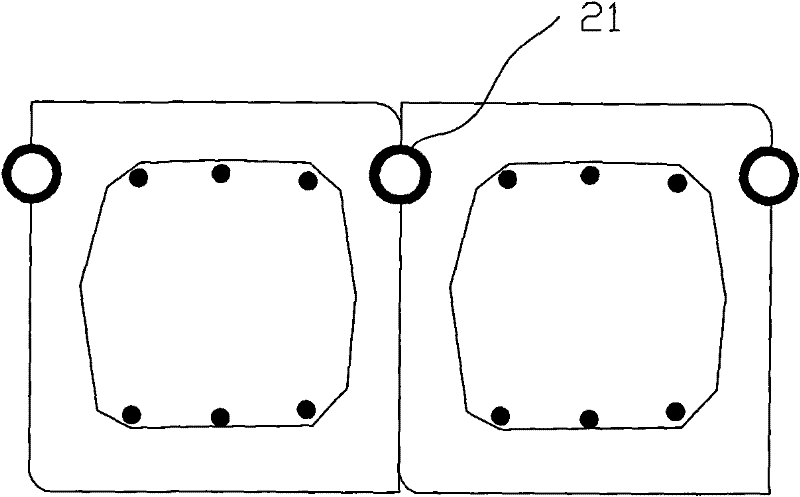

[0048] Preserve holes to splice the surrounding protection piles, such as Figure 1 ~ Figure 3 shown.

[0049] The above-mentioned enclosure pile is a solid pile, and its processing method is as follows:

[0050] a, prepare the steel cage skeleton;

[0051] b. Prepare high-performance concrete and prepare matching molds, and apply isolation lubricant on the molds;

[0052] c. Install the reinforcement cage on the mold and tighten the tension device;

[0053] d. According to the flexural performance of the product, pre-tension the steel bar, lock and anchor after meeting the requirements; do not stretch the steel bar if there is no pre-stress requirement;

[0054] e. Feed the prepared high-performance concrete into the steel mold, and start the vibration equipment at the same time to vibrate and compact;

[0055] f. Demoulding after steam curing;

[0056] g. The finished products shall be stacked according to the requirements of cement hardening, and shall be cured naturally...

Embodiment 2

[0063] Preserve holes to splice the surrounding protection piles, such as Figure 4 ~ Figure 6 shown.

[0064] Above-mentioned enclosure pile is hollow pile, and its processing method is:

[0065] a, prepare the steel cage skeleton;

[0066] b. Prepare high-performance concrete and matching molds, and apply isolation lubricant on the molds;

[0067] c. Install the reinforcement cage on the mold and tighten the tension device;

[0068] d. Feed the prepared high-performance concrete into the steel mold, pre-tension the steel bars according to the bending resistance of the product, and lock and anchor after reaching the required value;

[0069] E, put into centrifuge and carry out centrifugation and pour out the remaining pulp;

[0070] f. Demoulding after steam curing;

[0071] g. The finished products shall be stacked according to the requirements of cement hardening, and shall be cured naturally or with water according to the requirements of cement hardening.

[0072] Th...

Embodiment 3

[0078] Preserve holes to splice the surrounding protection piles, such as Figure 7 shown.

[0079] The above-mentioned enclosure pile is a solid pile, and its processing method is as follows:

[0080] a. Prepare high-performance concrete and matching molds, and apply isolation lubricant on the molds;

[0081] b. Feed the prepared high-performance concrete into the steel mold;

[0082] c, put it into the centrifuge and centrifuge and pour out the remaining pulp;

[0083] d. Demoulding after steam curing;

[0084] e. The finished products are stacked according to the requirements of cement hardening, and are naturally cured or water cured according to the requirements of cement hardening.

[0085] The dry weight components of the above-mentioned isolation lubricant are: sodium alginate 10, emulsifier Tween3, emulsifier Spam3, graphite 5 parts, filler talcum powder 80 parts by weight, add water 5 times by weight and mix and stir evenly;

[0086] The above-mentioned steam cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com