Clean room micro slope terrace and construction method thereof

A clean room and slope technology, applied in the directions of floors, buildings, building structures, etc., can solve the problems of difficulty in meeting the requirements of smoothness, antibacterial and moisture-proof, increasing the thickness of concrete leveling layers, and uneven ground heights, so as to improve cleanliness, quality and convenience. The effect of construction organization and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

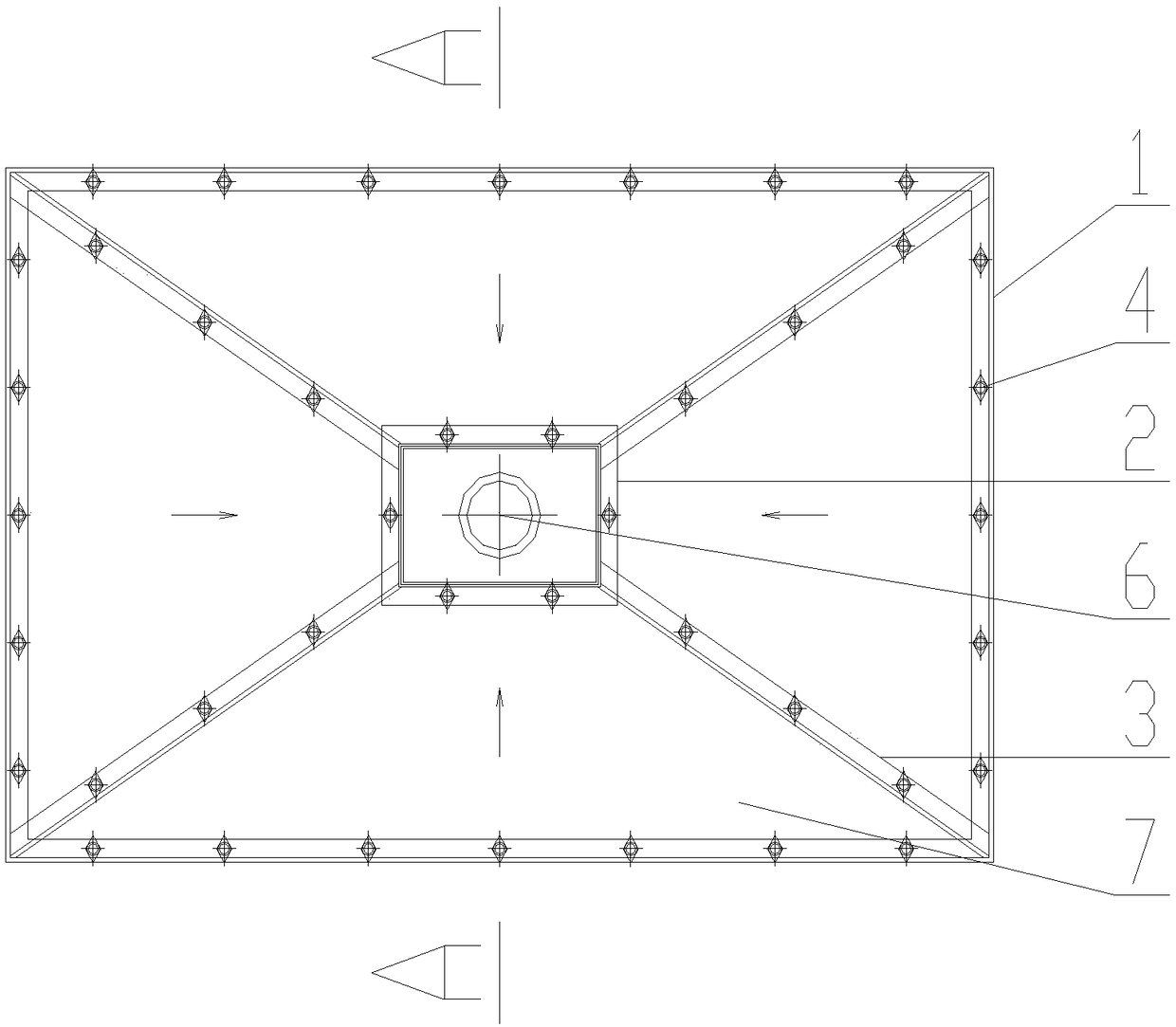

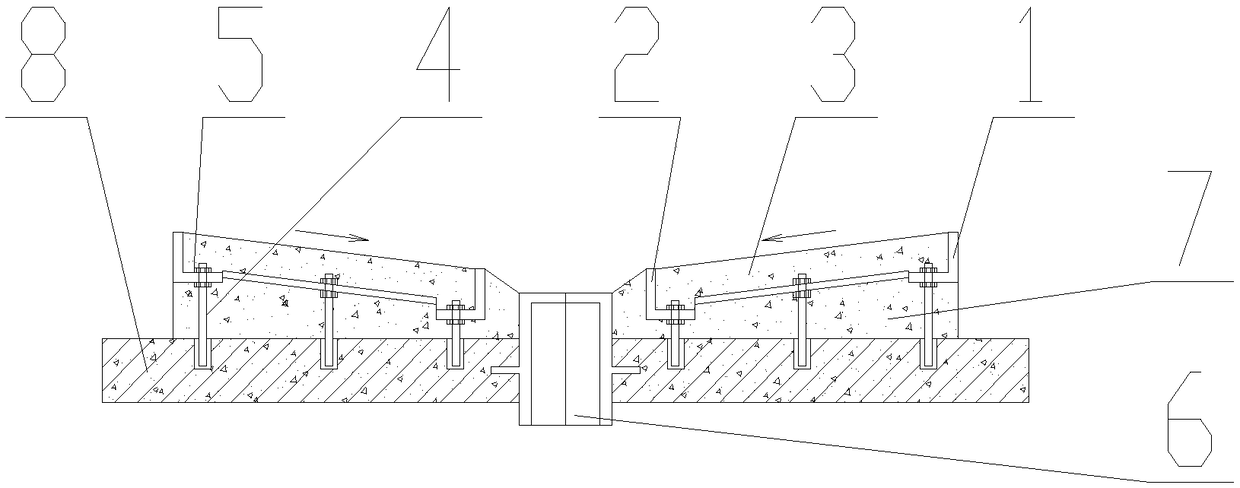

[0026] Such as Figure 1 to Figure 2 The shown clean room micro-slope floor includes a structural layer 8 with multiple drainage slopes on the surface of the structural layer 8. The center of the structural layer 8 is fixedly connected to a floor drain 6, and the lower end of the floor drain 6 is connected to an underground water pipe. The structural layer 8 An angle steel frame is provided above the angle steel frame. The angle steel frame includes an angle steel outer frame 1 and an angle steel inner frame 2. The angle steel inner frame 2 is located at the center of the structural layer, and the angle steel outer frame 1 is located outside the angle steel inner frame 2. The opposite corners of 2 are fixedly connected with a boundary connection angle steel 3, and the angle steel outer frame 1, the angle steel inner frame 2 and the limb back side of the boundary connection angle steel 3 are equidistantly provided with a plurality of bolt holes, and each bolt hole is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com