Prefabricated column and precast construction method thereof

A construction method and technology of prefabricated columns, applied in the direction of columns, piers, pillars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

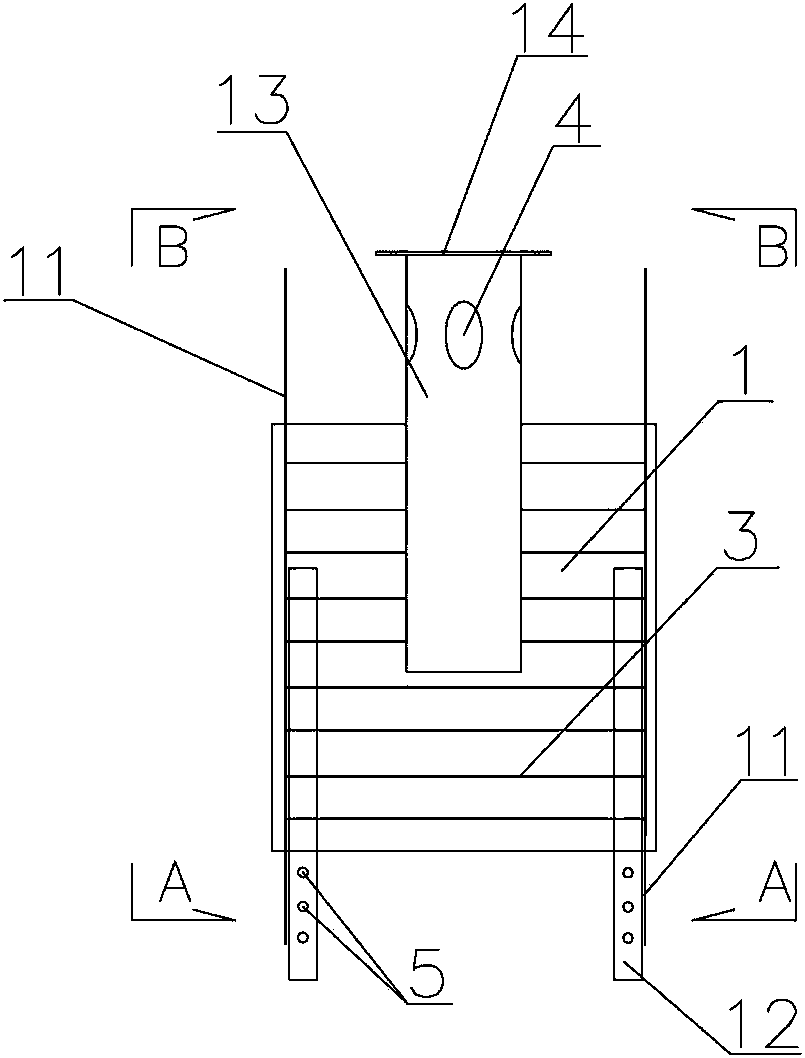

[0041] Please refer to the attached figure 1 to attach Figure 7 As shown, the present invention is a prefabricated column, which includes a lower prefabricated column 1 and an upper prefabricated column 2 matched with the lower prefabricated column 1 . The lower precast column 1 can be connected up and down with the upper precast column 2 on the same floor, or connected up and down with the upper precast column 2 on the next floor.

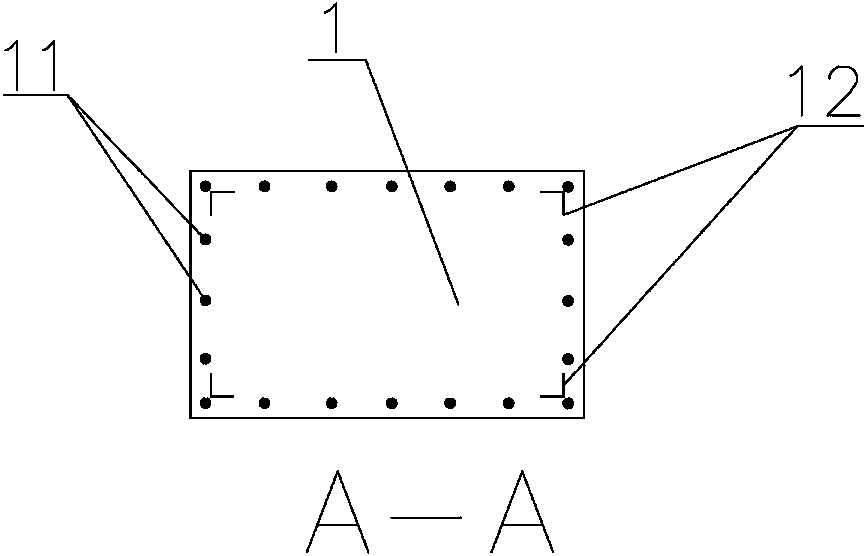

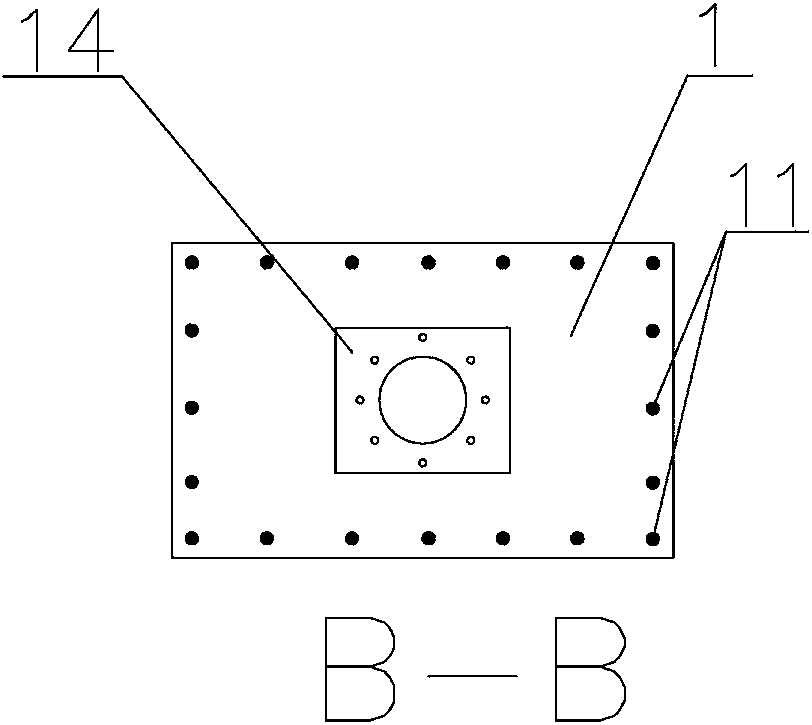

[0042]Wherein, the length of the lower prefabricated column 1 is 1000-1500 mm, and a first vertical steel bar 11 is arranged inside, and the first vertical steel bar 11 extends out of the upper and lower ends of the lower precast column 1 . The lower end of the lower prefabricated column 1 is provided with a first connecting piece 12 , and the upper end is provided with a first steel pipe 13 and a first flange 14 welded on the top surface of the first steel pipe 13 .

[0043] The upper precast column 2 is provided with a second vertical steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com