Screw pin clamping plate joints, independent frame, independent mold frame and construction method of independent mold frame

A technology of screw pin and plywood section, which is applied in the direction of formwork/template/work frame, connection parts of formwork/formwork/work frame, and processing of formwork, which can solve the problems of scattered construction and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

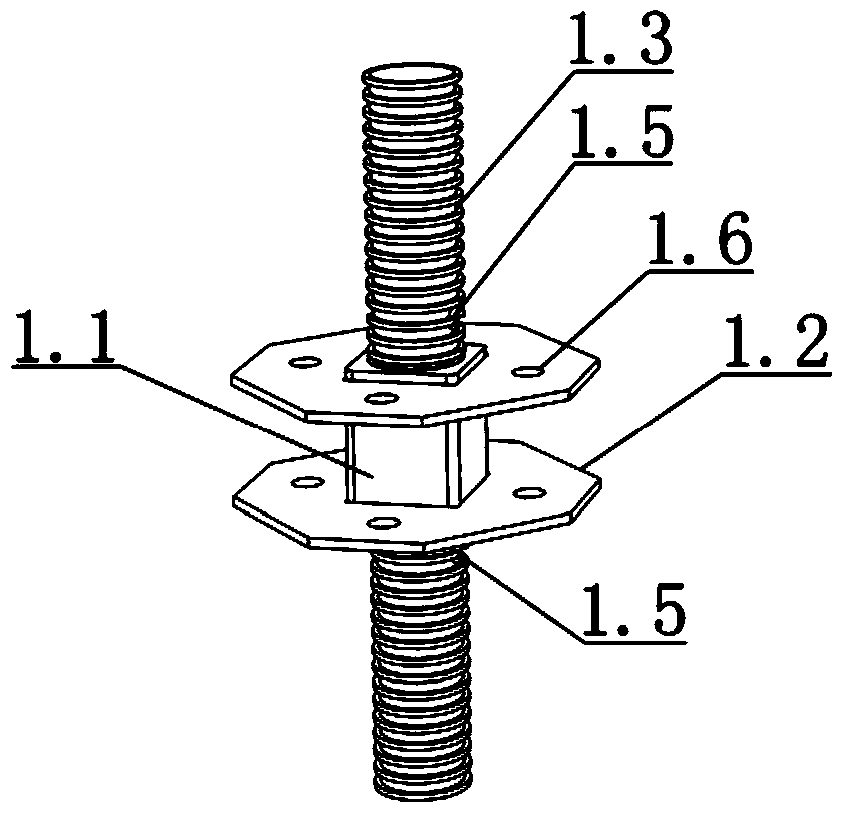

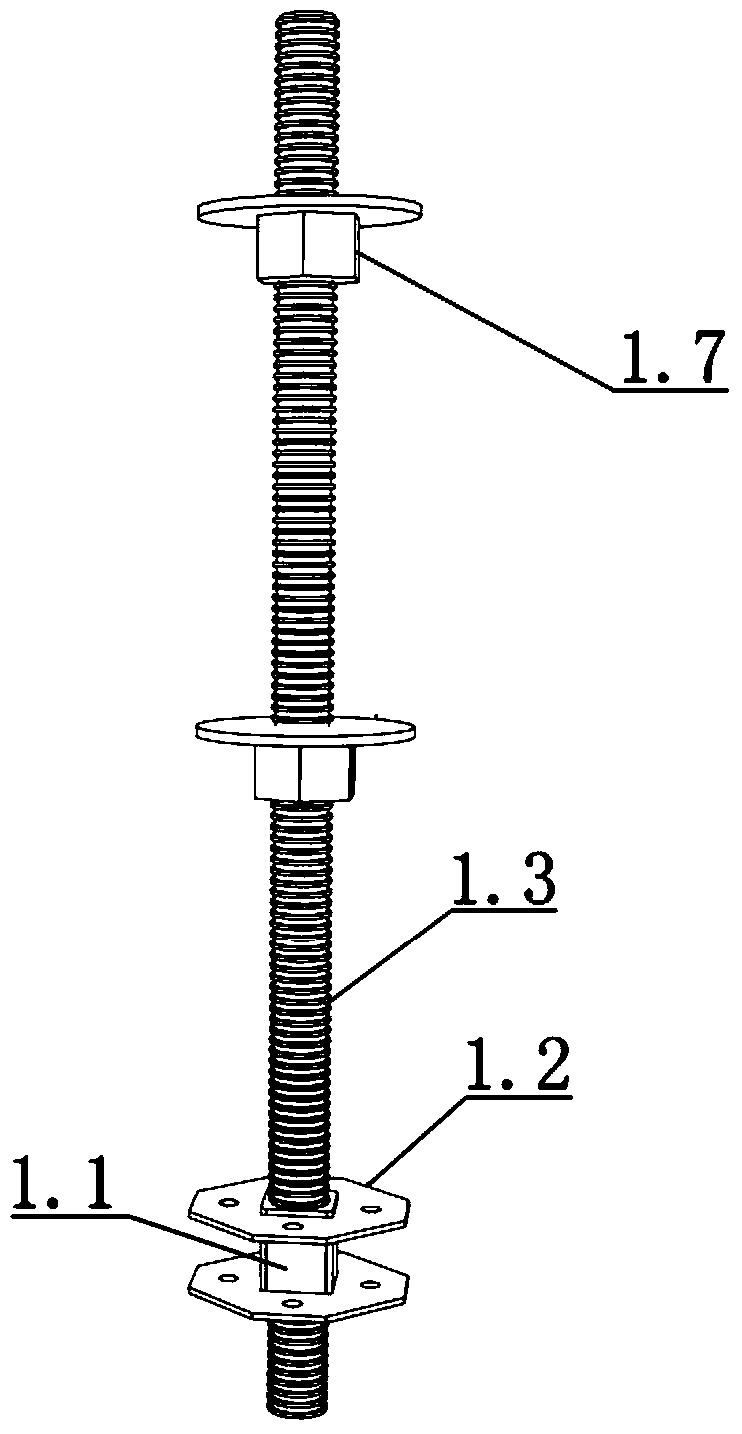

[0209] Example 1 see Figure 1-5 As shown in the screw pin splint section, the screw pin splint section 1 is composed of a joint core 1.1, a splint 1.2 and a screw pin 1.3.

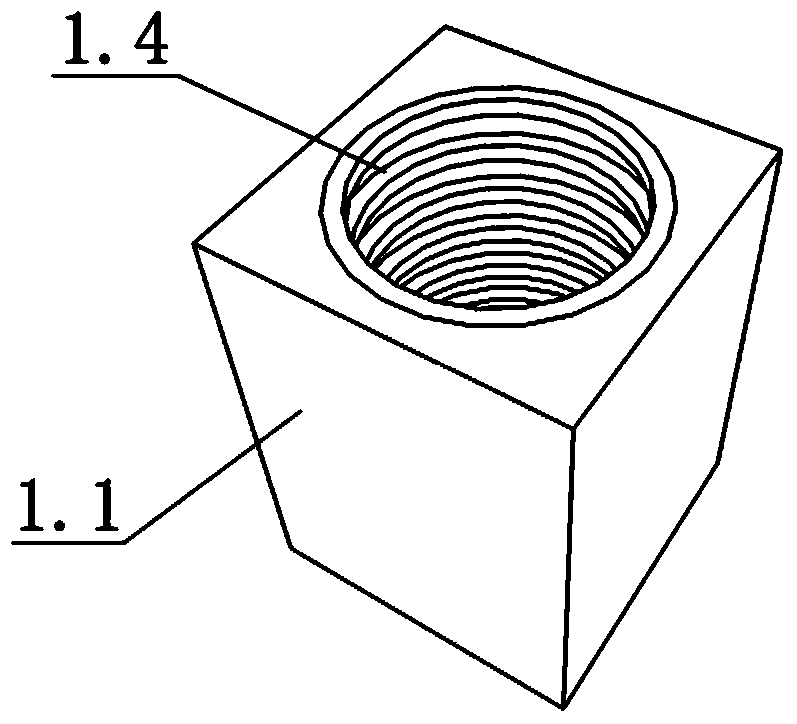

[0210] The joint core 1.1 is a block, a round block or a polygonal block; a screw hole 1.4 is opened on the joint core.

[0211] The screw pin 1.3 is a circular pin, and the screw pin 1.3 is screwed in the screw hole 1.4.

[0212] The upper and lower ends of the screw pin 1.3 protrude from the joint core 1.1 to form a pin joint; the pin joint can be provided with a positioning hole 1.5 or a limited-rotation bayonet.

[0213] The splint 1.2 is composed of two opposite horizontal plates. The horizontal plate protrudes from the side of the joint core 1.1 around the joint core. The horizontal plate includes a square plate, a circular plate or a polygonal plate; The hole sleeve is fixed on the joint core 1.1; the splint 1.2 is provided with connection holes 1.6 corresponding to four directions of the plane, ...

Embodiment 2

[0214] Example 2 see Image 6 , Figure 25-27 As shown, different from Example 1, the joint nucleus 1.1 of Example 2 has a constriction head 1.8 at the upper end, the lower end or the upper and lower ends, and the cross section of the constriction head is quadrilateral or polygonal, with There are external threads; the cross-section of the joint core 1.1 protrudes outward from the cross-section of the shrinking head 1.8, and the protruding part forms a cardan 1.10.

[0215] The splint 1.2 is fixed on the shrinking head 1.8 of the joint core through the core hole, and is fixed by the clamp 1.10.

[0216] On the shrinkage head 1.8, screw the inherent knot nut 1.9.

[0217] The joint core 1.1 and splint 1.2 are connected in series with screw pin 1.3, and fastened with joint core nut 1.9 to form a screw pin splint joint.

[0218] The joint core nut 1.9 is a double-diameter nut, which is screwed on the shrinkage head 1.8 with the large-diameter hole 1.91, and forms a pin hole wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com