Verticality control device for vertical structural column of integral steel platform formwork and construction method

A technology of vertical structure and control device, applied in the direction of measuring device, house structure support, house structure support, etc., can solve problems such as hidden safety hazards, lack of verticality deviation data of disassembly and assembly positions, etc., achieve structure optimization, reduce adverse effects, Highly intelligent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

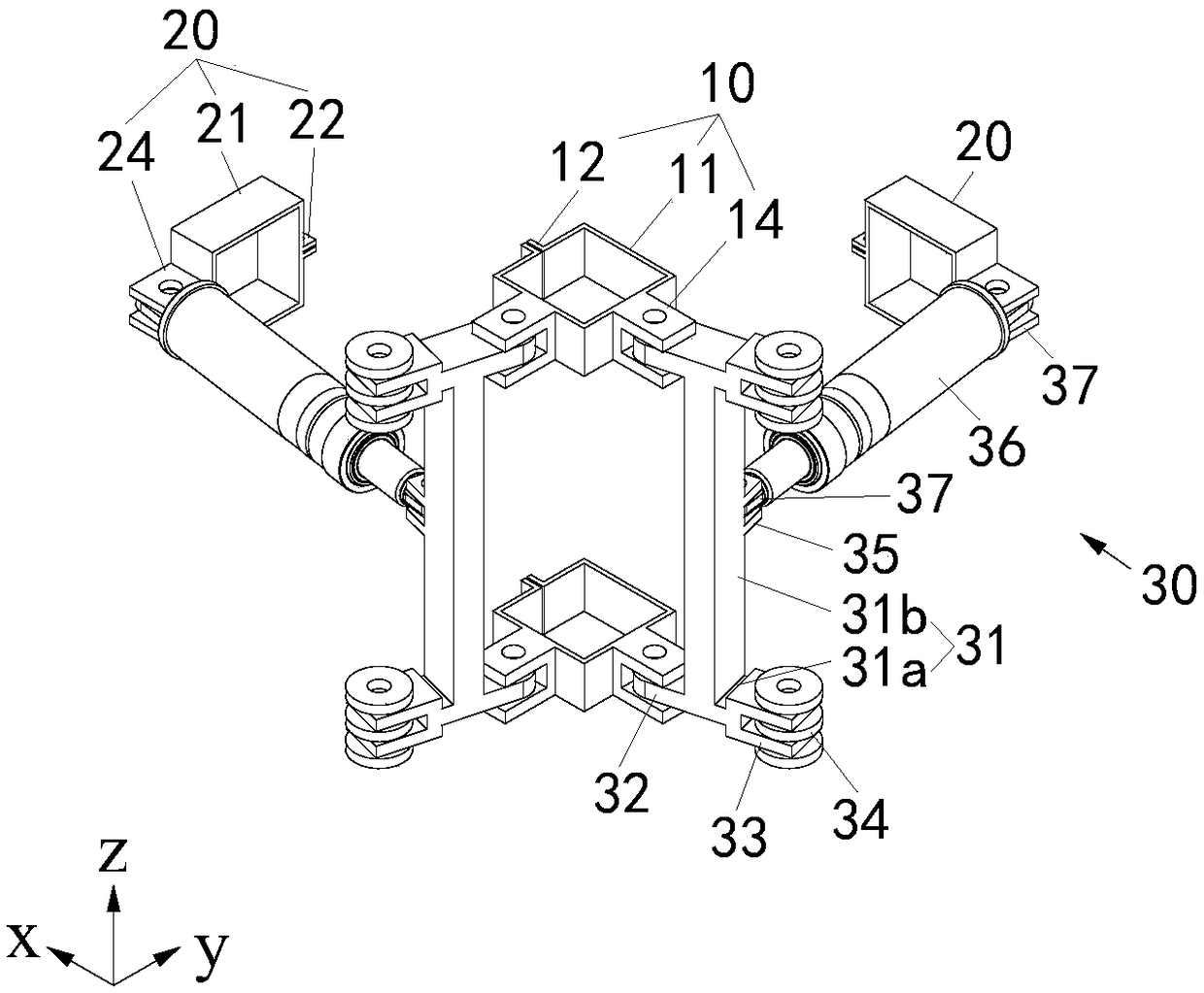

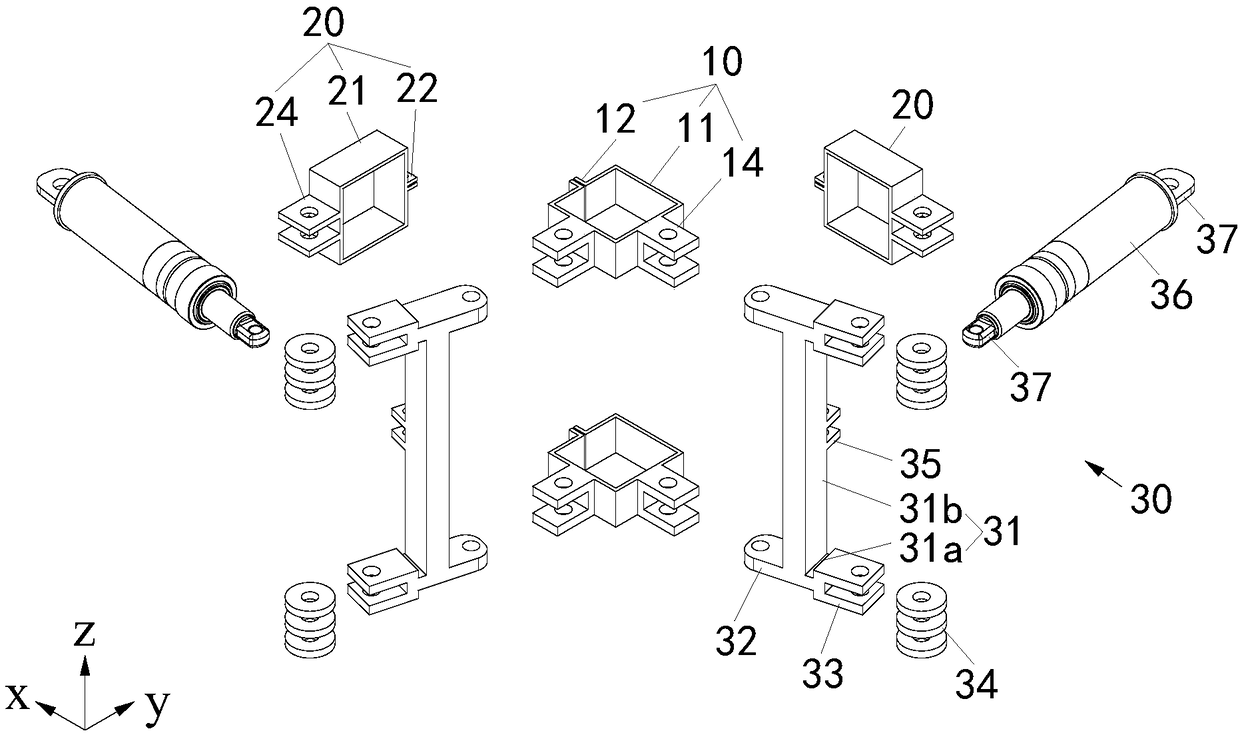

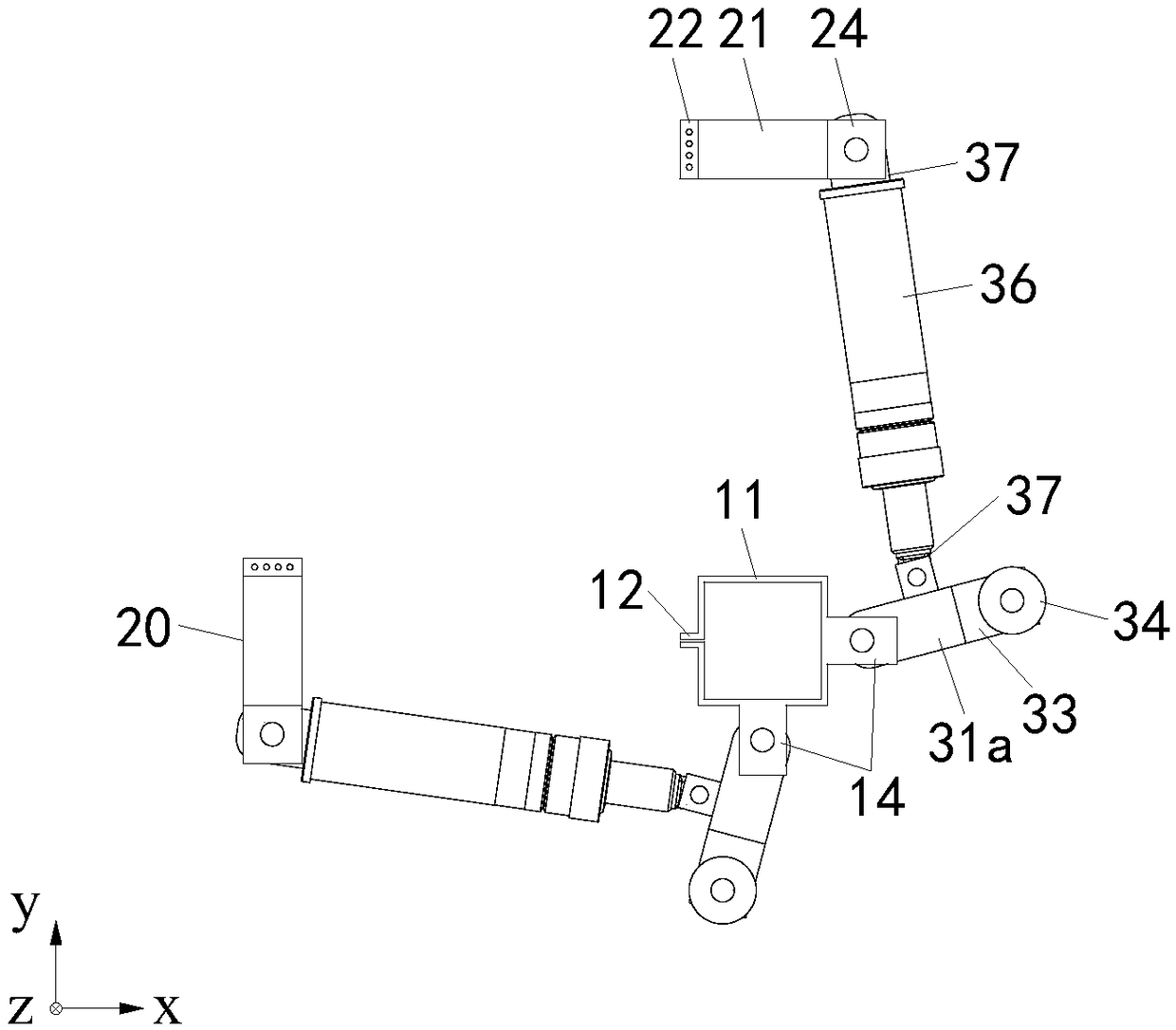

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention. For the convenience of description, the "up" and "down" described below are consistent with the directions of up and down in the drawings, but this should not be a limitation of the technical solution of the present invention.

[0043] The vertical structural column is an important load-bearing component of the overall steel platform formwork. The verticality of the vertical structural column directly affects whether the vertical force of the formwork of hundreds of tons can be smoothly transmitted to the reinforced concrete core tube, and it can also reflect the overall The degree of inclination of the steel platform form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com