Jacking construction method for assembled-type external elevator shaftway structure

A technology for elevator shafts and construction methods, which is applied to building structures and constructions, can solve problems such as hidden safety hazards, limited site space, and long construction periods, so as to avoid high-altitude operations, improve construction efficiency, and shorten construction periods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

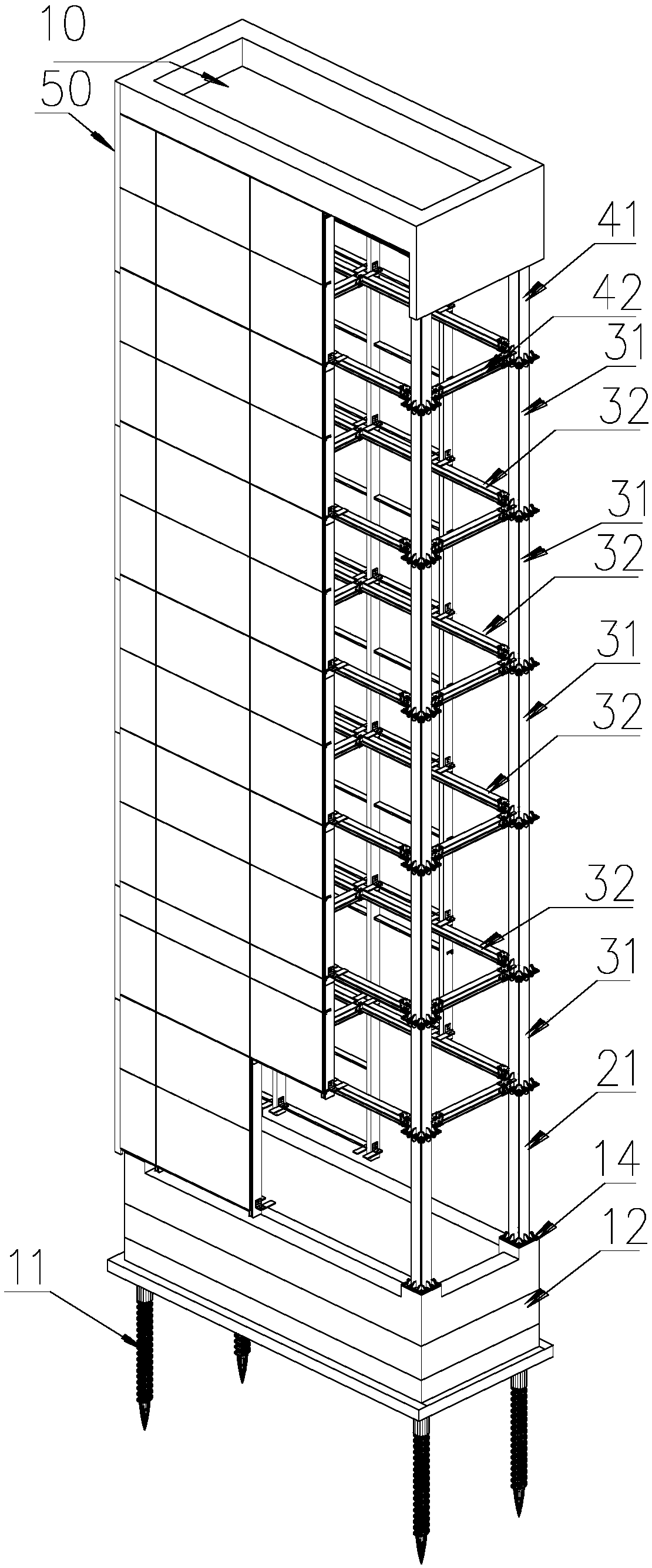

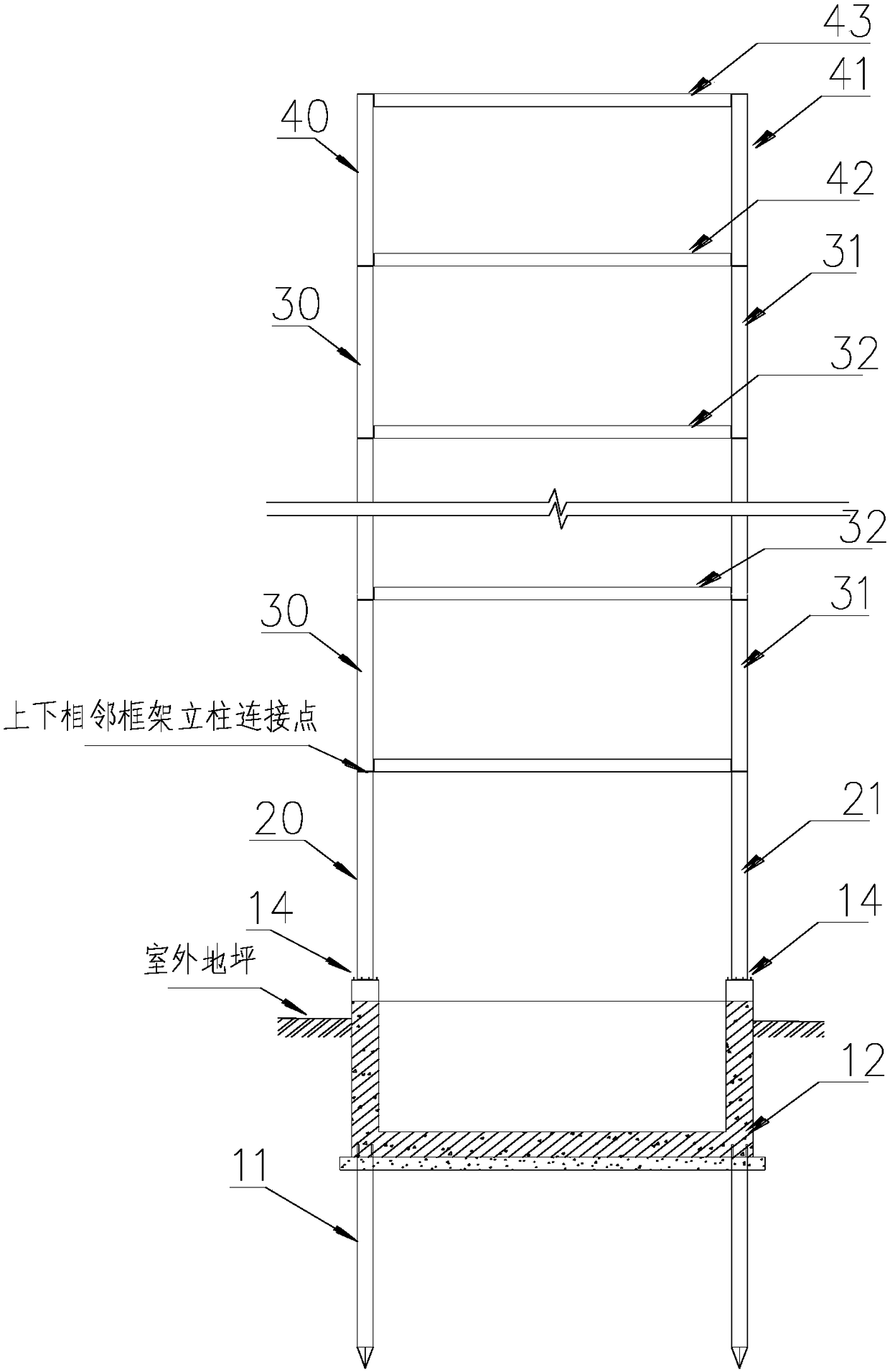

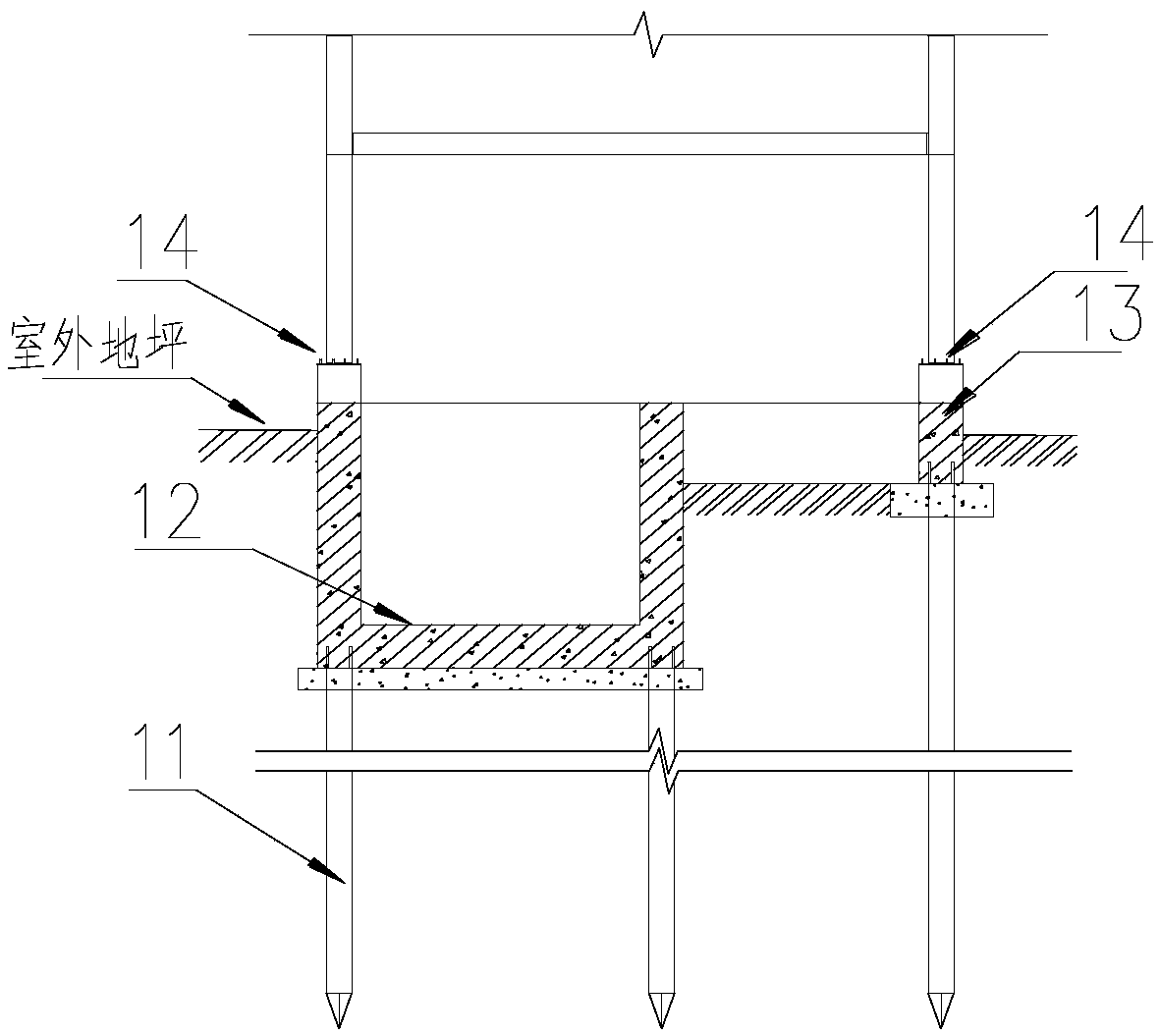

[0046] Such as figure 1 with figure 2 As shown, the jacking construction method of the prefabricated additional elevator shaft structure of the present invention is to install the prefabricated additional elevator shaft structure, including foundation, prefabricated steel frame support structure, light curtain wall enclosure structure 50 and roof 10. The foundation is an independent foundation, and according to the requirements of the corresponding building codes, settlement joints and anti-seismic joints are set at the corresponding floor slabs and outer walls of the existing buildings. According to the specific engineering geological conditions, the foundation adopts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com