Under ring spindle device for spinning filament covered yarn

A ring-spinning, bottom-mounted technology, which is applied to the spinning machine, continuous winding spinning machine, yarn, etc., can solve the problems of inconvenient operation, jointing, affecting the overall layout of the workshop, and inconvenient maintenance. Achieve the effects of convenient operation, improving work efficiency and yarn quality, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

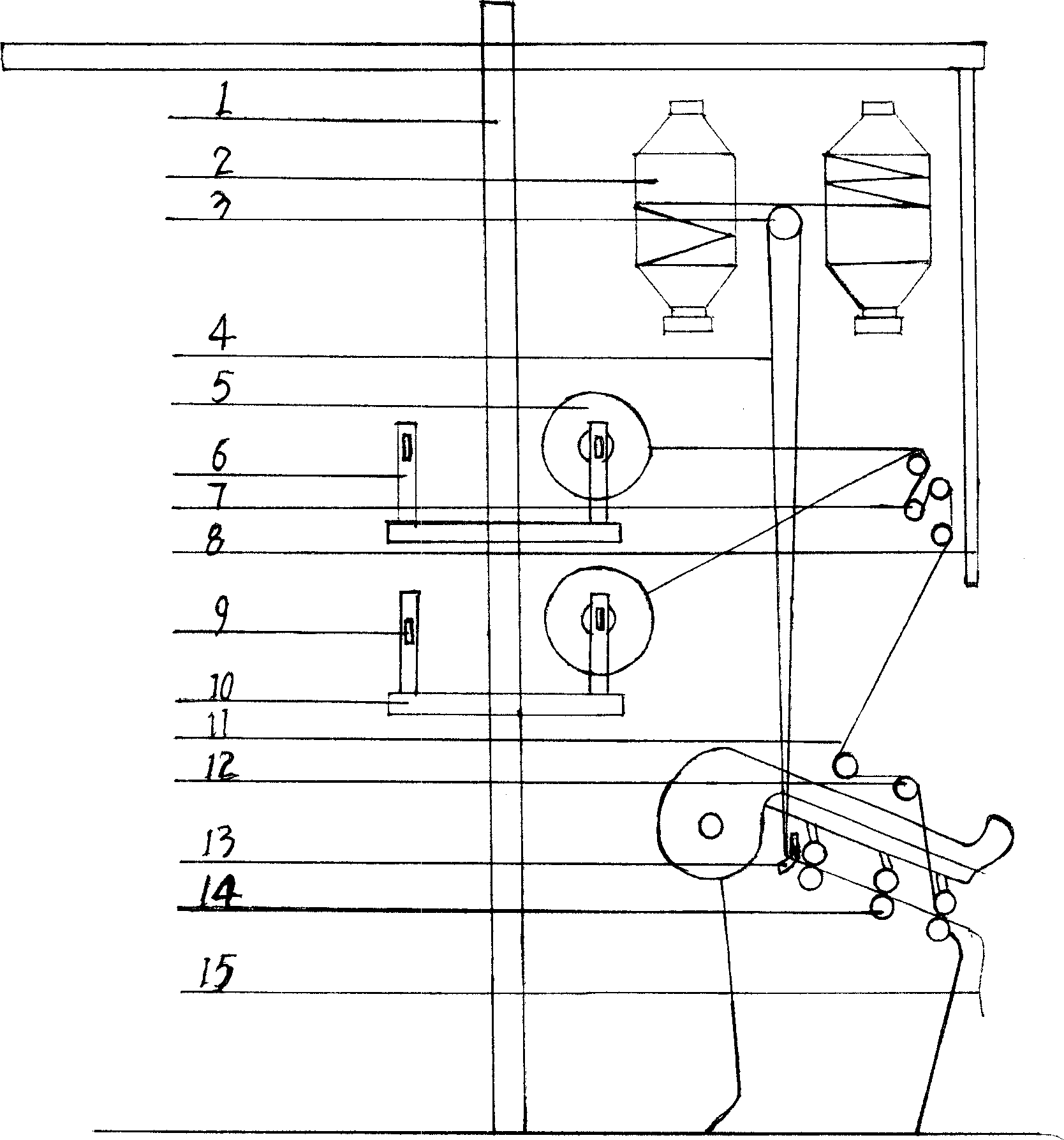

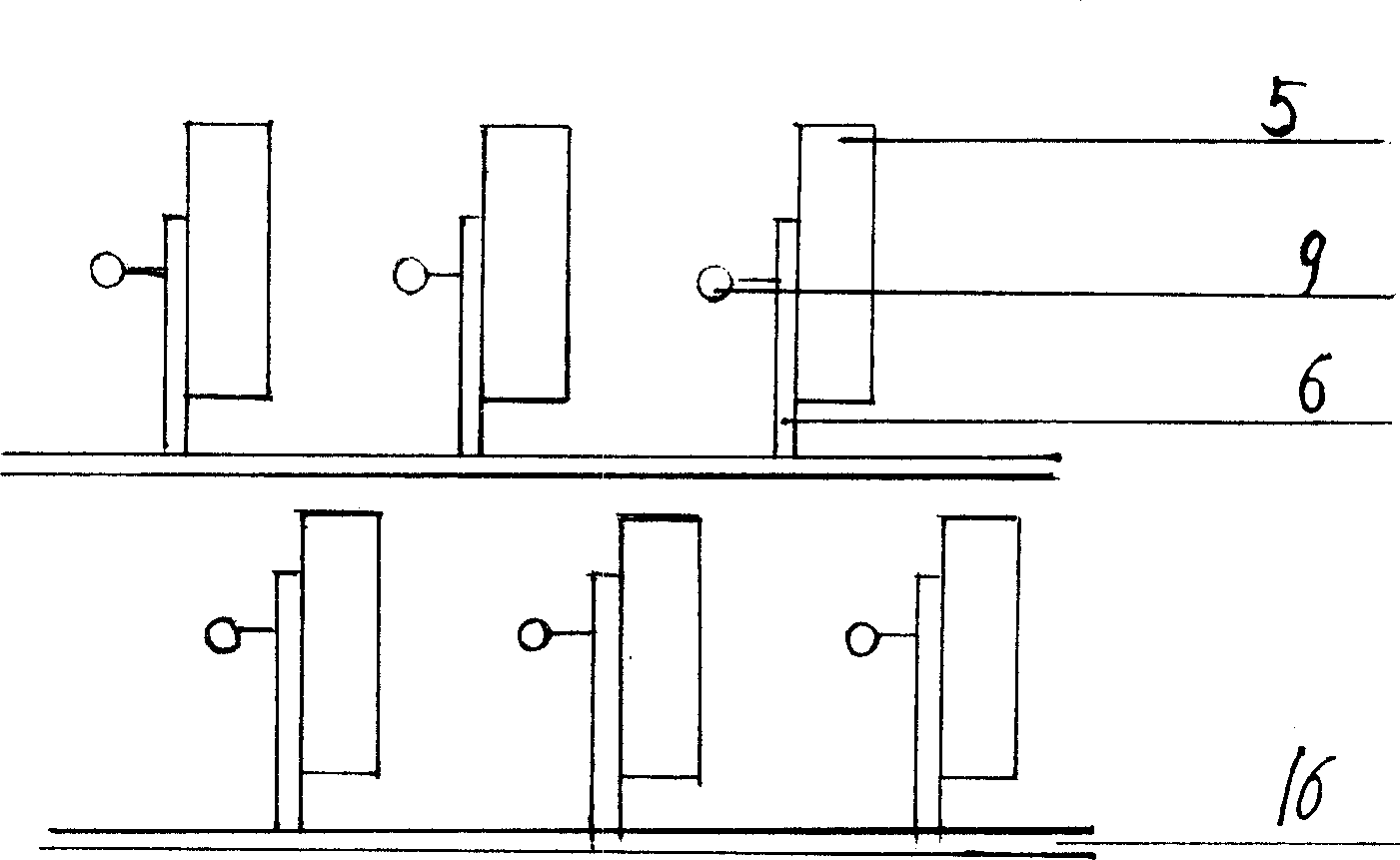

[0021] The best implementation modes of the present invention are given below in conjunction with the accompanying drawings, which are used to further illustrate the present invention.

[0022] refer to Figure 1-2 , in the accompanying drawings, the bottom-mounted ring spinning filament covered yarn device of the best embodiment is composed of a roving support mechanism, a filament cake support mechanism, a four-bar tension mechanism, and a spinning frame understretching mechanism. The roving support mechanism is composed of a fixed The roving frame support rod 1 on the frame and the roving frame fixed on the roving support rod 1 are composed, and the roving frame is used to place the roving cake 2; 10 constitutes with the filament cake support frame 6 fixed on the longitudinal bracket 10, the filament cake support frame 6 is used to place the filament cake 5, and the filament cake support frame 6 is equipped with a wire guide hook 9; the four-bar tension mechanism It is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com