Special construction method for dragging main beam of extra-large bridge

A technology for extra-large bridges and main girders, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as construction structures, high technical requirements for equipment, large investment in construction equipment, and difficult construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

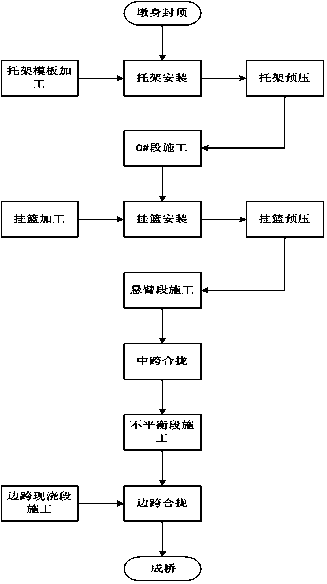

[0091] The special construction method for the main girder of the Xiatuo Super Bridge, such as figure 1 As shown, the 0# section of the main girder and the cast-in-place section of the side spans of the Xiatuo Super Bridge are constructed by bracket cast-in-place construction, as shown in Figure 7-9 As shown, the cantilever section is constructed with a diamond-shaped hanging basket, and the construction content is as follows:

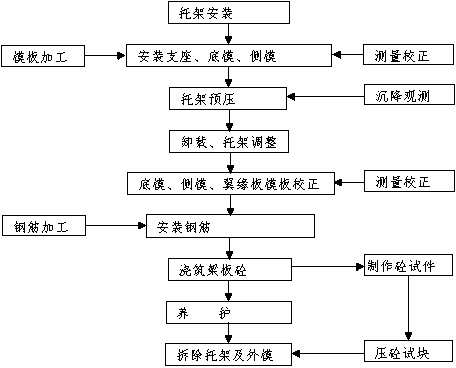

[0092] Phase 1: Bracket Installation

[0093] 1. For the capping construction of the pier body, install the embedded parts of the bracket and the embedded steel strands.

[0094] 2. After the main pier is capped, the hydraulic climbing formwork is removed, and the platform frame is reserved as a bracket installation and operation platform. The flat bar and inclined bar of the bracket are assembled on the ground, and are temporarily connected by steel cables to form an installation angle. The sling is put on the flat bar, and the posture is roughly t...

Embodiment 2

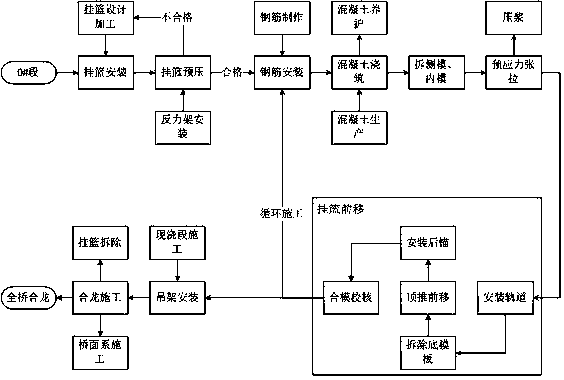

[0149] This embodiment is optimized on the basis of embodiment 1, such as Figure 4-6 As shown, the construction of the 0# section of the main beam is as follows:

[0150] 1. Bracket design

[0151] The 0# block bracket is the main load-bearing structure of the 0# block box girder concrete cast-in-place. It is required to have sufficient strength and rigidity to drag the 0# section of the main girder of the super-large bridge. , with a weight of 221.3t, poured in two times, and the design of the bracket is considered as one pouring. The main components of the 0# block bracket are embedded anchors, main brackets, side brackets, distribution beams, leveling frames, platform plates, and formwork systems.

[0152] The pre-embedded anchor seat is tailor-welded with δ20 steel plate, embedded in the concrete of the pier body, the exposed part is 45cm long, and the pin hole is reserved for pin connection with the bracket rod. The main bracket is the same as the anchor seat of the s...

Embodiment 3

[0185] The present embodiment optimizes on the basis of embodiment 1 or 2, and the hanging basket construction is as follows:

[0186] 1. Hanging basket design: The hanging basket adopts a diamond-shaped hanging basket. The main components of the hanging basket: it is composed of main truss, bottom formwork platform and hanging system, inner and outer formwork hanging and running system, rear anchorage, inner and outer forms, limit facilities, roofing system, etc.

[0187] 2. Main truss

[0188] Such as Figure 7-9 As shown, the main truss system of the diamond-shaped hanging basket is the main load-bearing structure of the hanging basket, and it mainly bears the vertical tension transmitted from the bottom formwork system in the suspension irrigation construction.

[0189] The main truss of the hanging basket is composed of upper flat bar, lower flat bar, front slanting bar, rear slanting bar, middle beam, bottom mold rear cantilever beam, and oblique support. Each bar is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com