Method for mounting reinforcing steel bars of tower columns of cable-stayed bridge towers

An installation method and the technology of cable towers, which are applied in the direction of cable-stayed bridges, bridges, bridge parts, etc., can solve the problems that affect the construction accuracy, the personal safety of construction personnel, the protracted construction period of the tower column, and the impact on the construction period, so as to avoid high-altitude operation, improve construction quality, and shorten construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

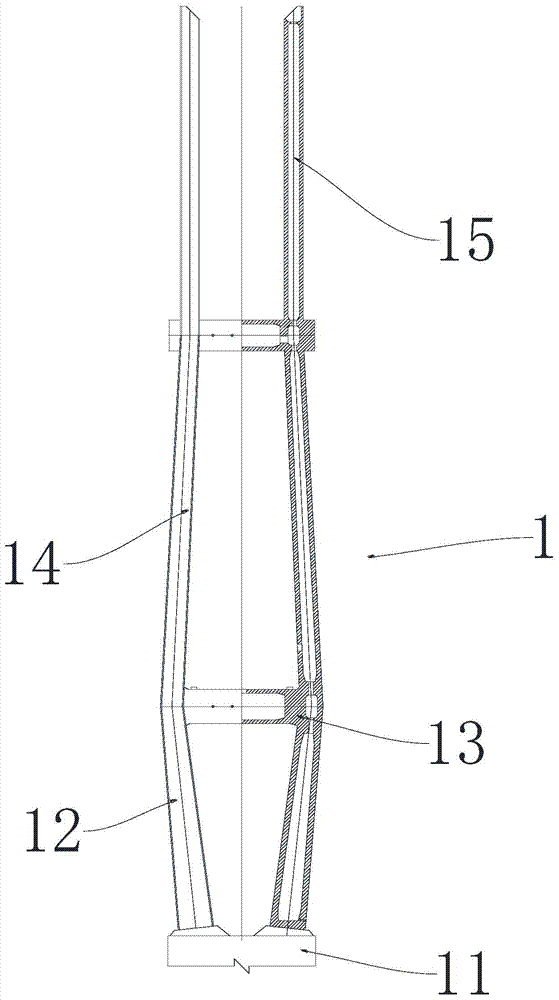

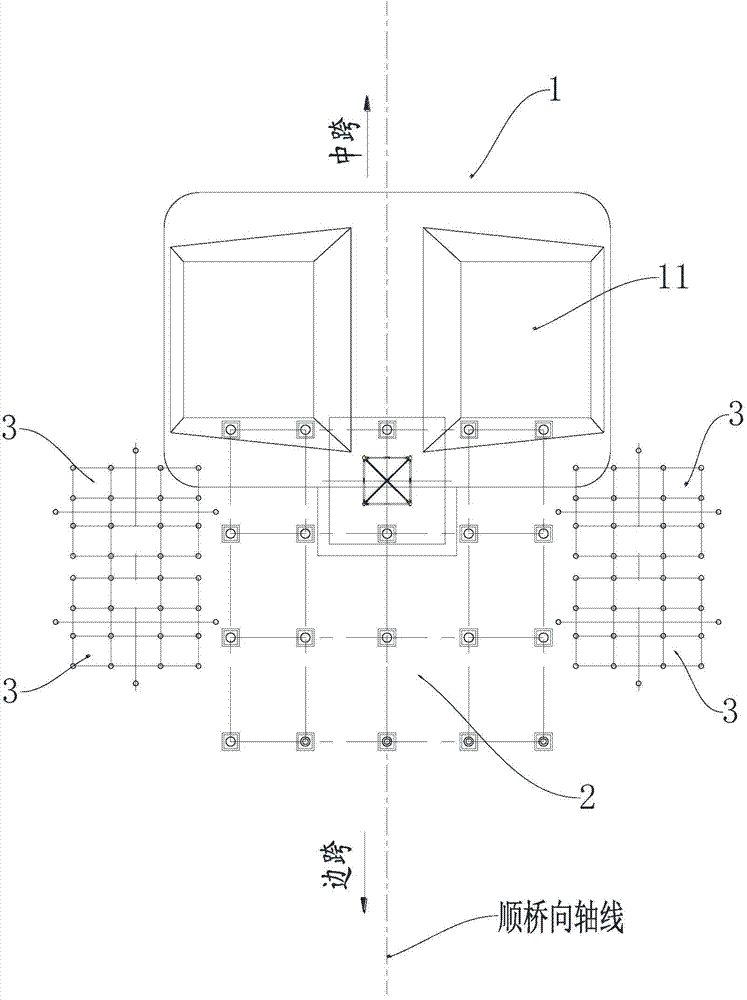

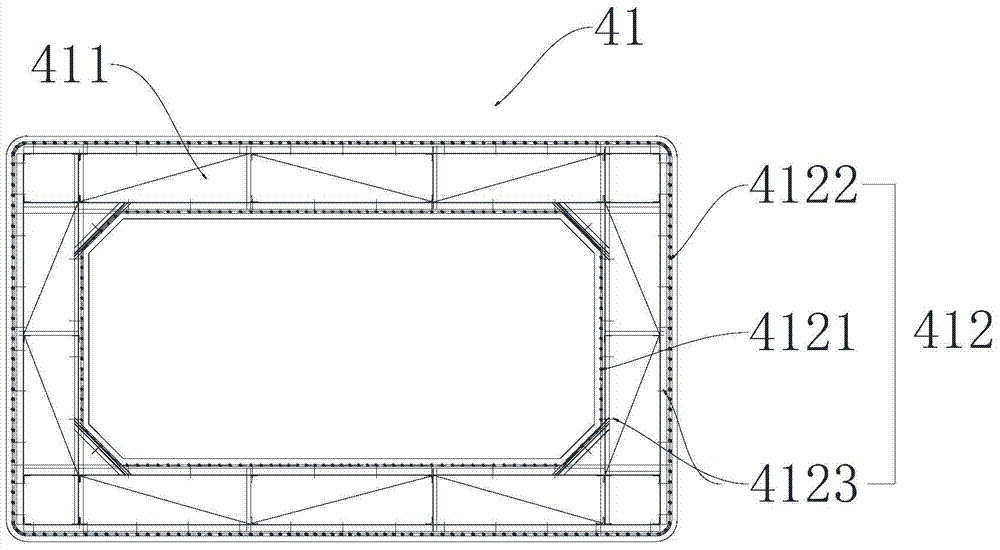

[0060] refer to Figure 2-12 , the installation method of the cable-stayed bridge tower column steel bar of the cable-stayed bridge of the present invention needs to utilize the tower crane 2 that is arranged near the cable tower 1 and the assembled tire frame 3 to complete. In this technical solution, the following definitions will be carried out: the bridge deck is defined as the middle span (or main span) to the longer section of the shore distance, and the shorter section definition to the shore distance for the side span. In this embodiment, on the side span side of the foundation cap 11 of the cable tower 1 that has been cast, the tower crane 2 is arranged along the bridge-direction axis of the bridge deck, and on both sides of the bridge-direction axis (such as figure 2 On the left and right sides of the axis in the middle),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com