Tunnel underground excavation pipe shed guide pipe drilling construction precision control method

A technology of precision control and guide pipe, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., to achieve the effect of effective control of precision and guarantee of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

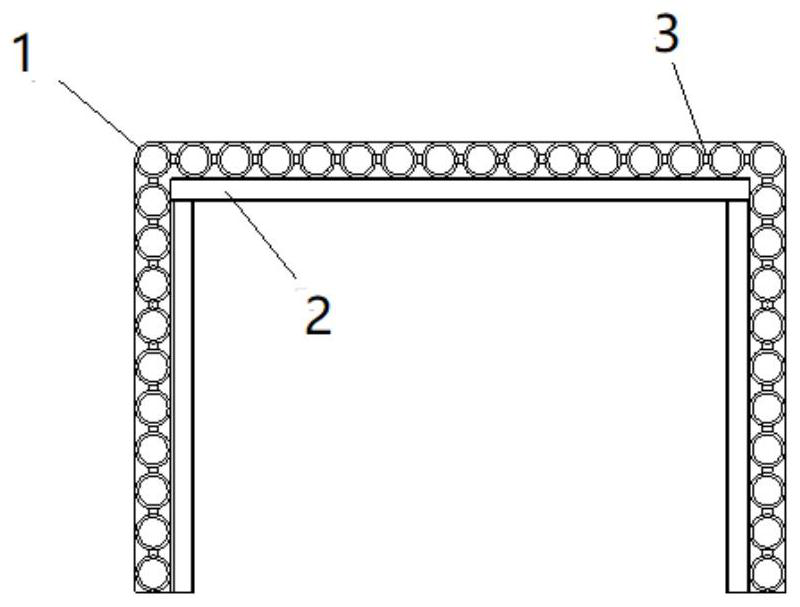

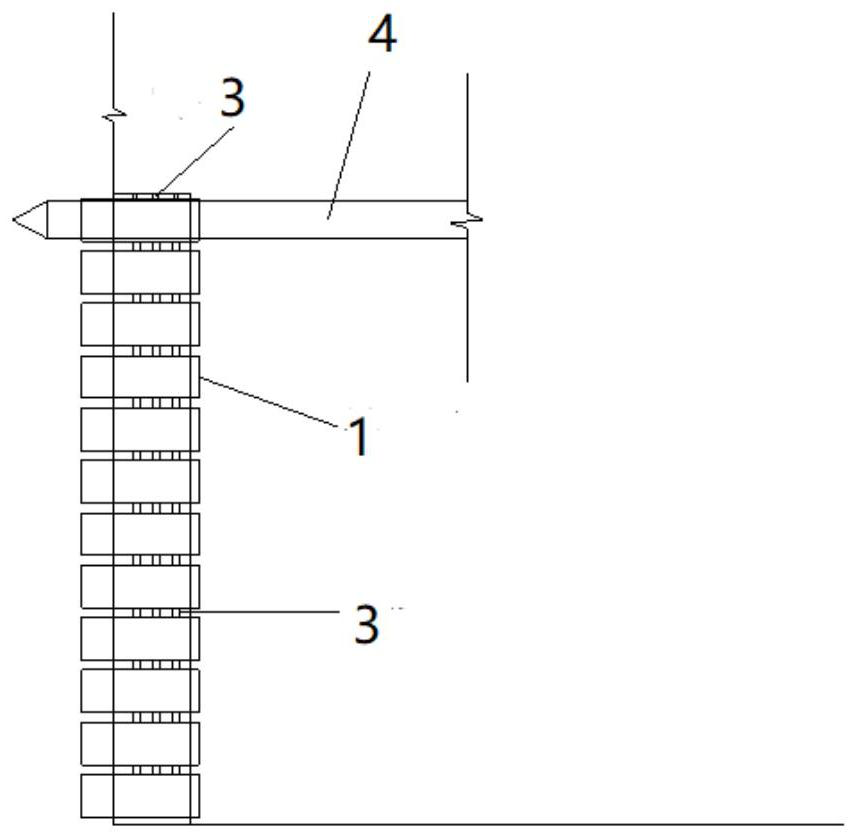

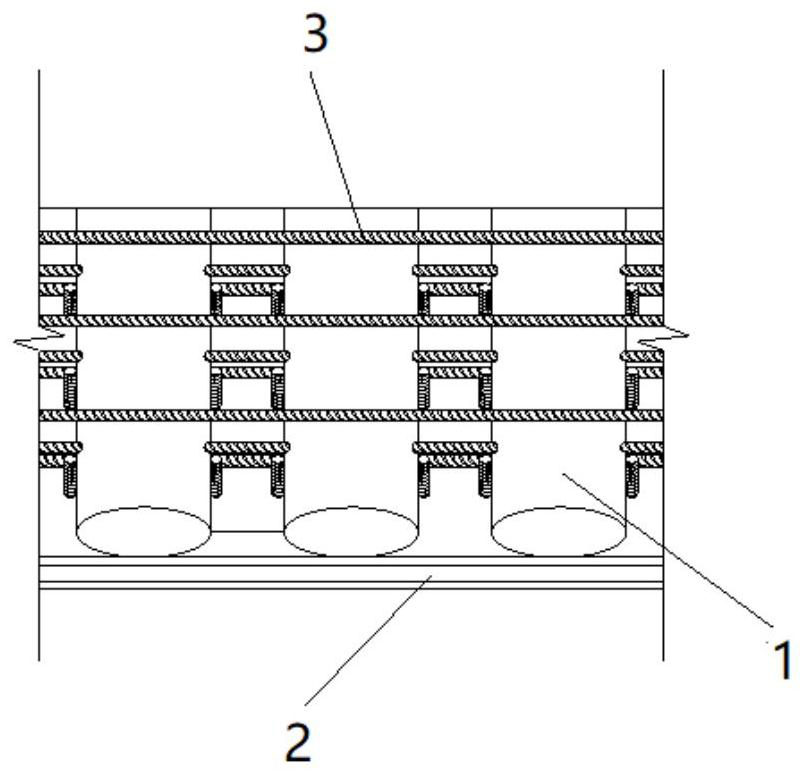

[0038] The present embodiment is a method for controlling the construction precision of the drilling of the guide pipe of the tunnel excavation pipe shed. The first part is the construction part of the guide wall, such as Figure 1-3 As shown, this part is mainly composed of guide pipe 1, I-beam 2 and some fixed steel bars 3, etc. After pouring is completed, a guide wall is formed, and its function is to provide guide positioning holes for the later construction of the pipe shed to ensure the construction process of the pipe shed. The second part is mainly about the control method of drilling construction accuracy, such as Figure 4-6 As shown, it mainly controls the vertical and horizontal direction precision of the tube shed tube 4 driven by the laser line casting instrument 5, so as to ensure the effective precision in the construction process of the advanced large tube shed. If the node position of the device is not specified, it shall be connected by welding.

[0039] B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com