A device for increasing material manufacturing rigid insulation tile body

A technology for additive manufacturing and thermal insulation tiles, which is applied in the field of devices for additive manufacturing of rigid thermal insulation tile blanks, can solve problems such as uneven density, and achieve the effects of uniform density, preventing deposition and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

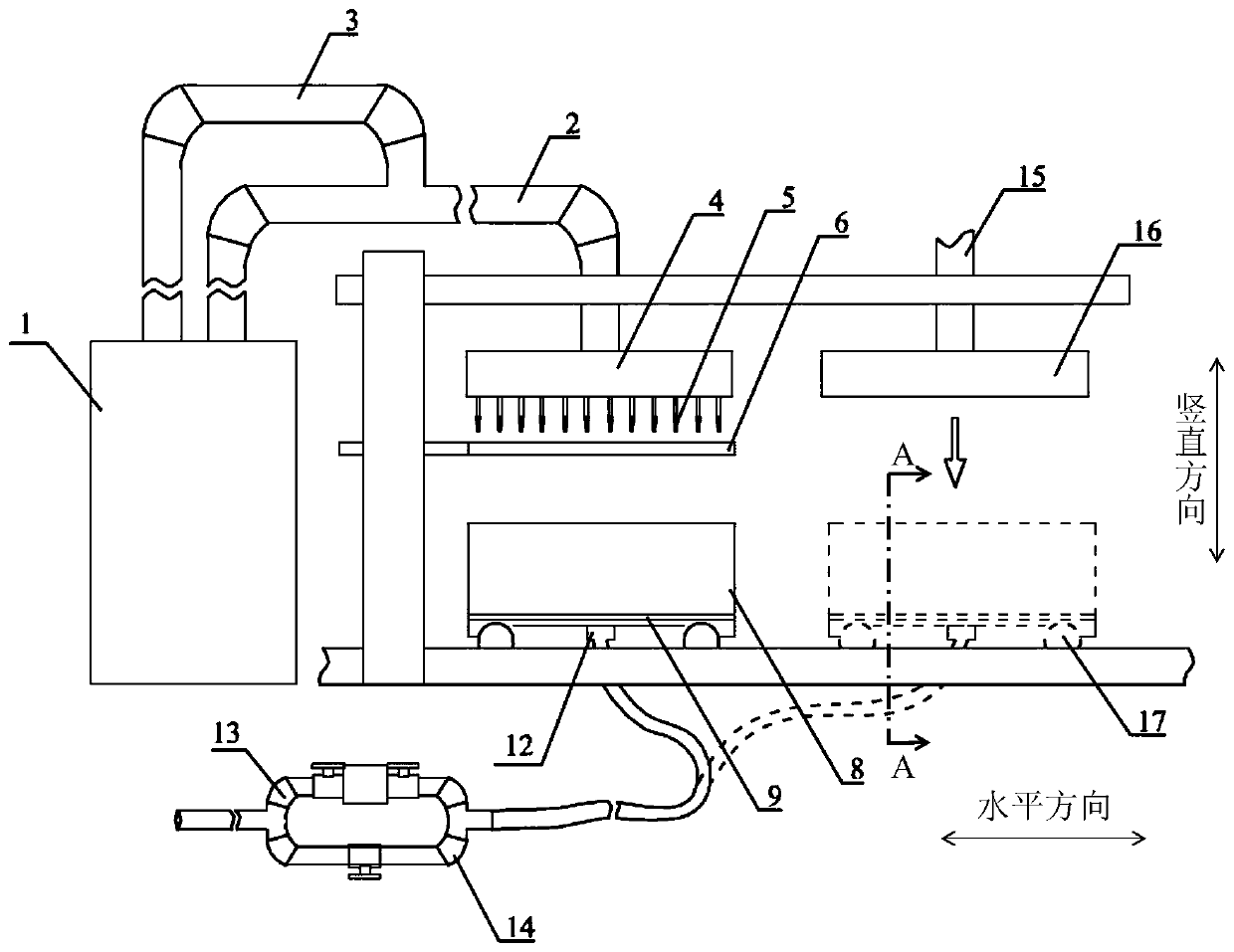

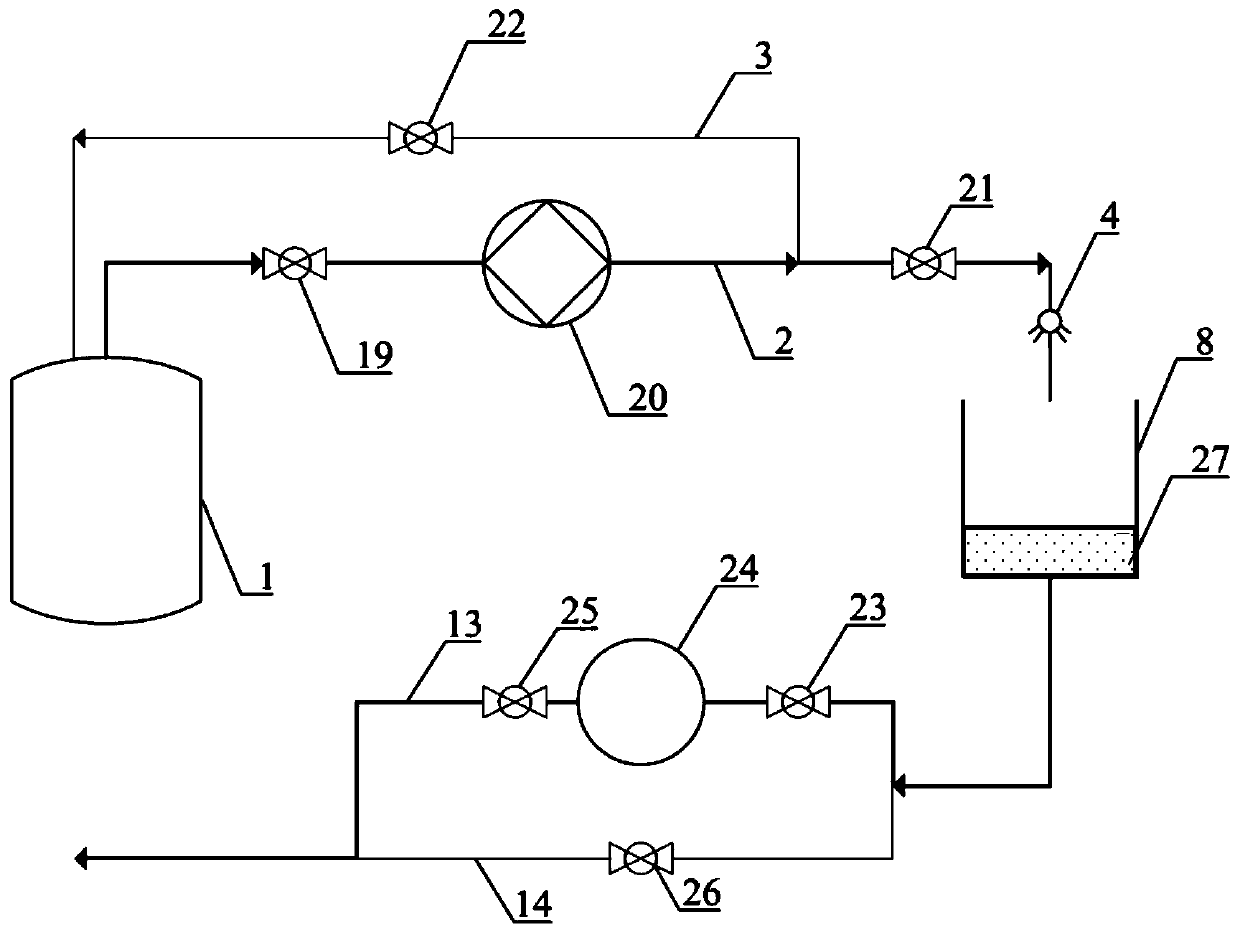

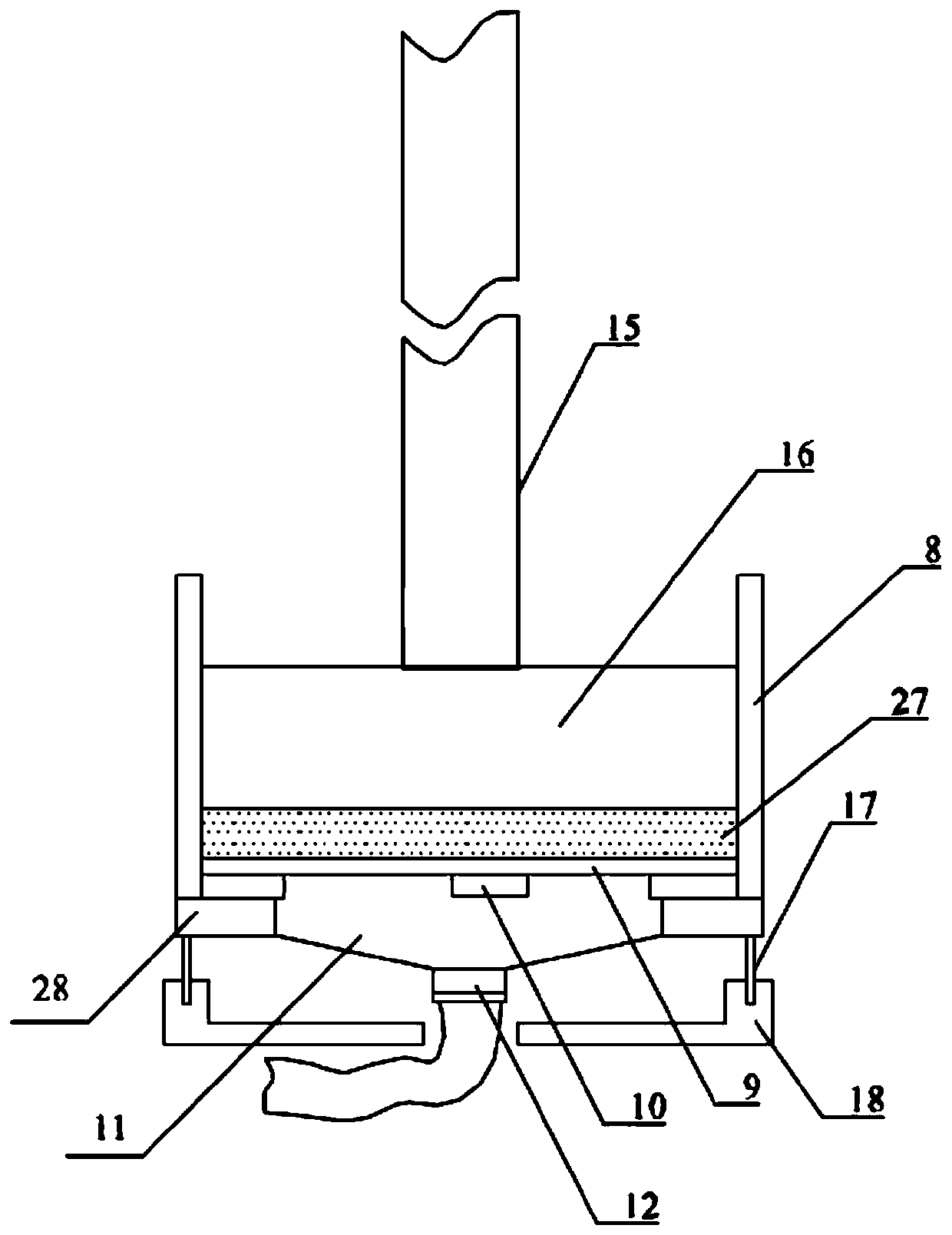

[0059] Manufacture of a device for the additive manufacturing of rigid insulation tile blanks, such as figure 1 shown. The device for additively manufacturing a rigid heat-insulating tile body includes a feeding system, a filter container, a drain pipe, a pressurizing device and an automatic control system (PLC controller, a first displacement sensor, a second displacement sensor, a pressure sensor and solenoid valve).

[0060] The filter container includes a peripheral wall, a bottom plate, a bottom net (30 mesh steel wire mesh), 3 lath-shaped reinforcing ribs arranged in parallel (through holes are provided on the reinforcing ribs) and a liquid collecting tank arranged below the reinforcing ribs. part, the liquid outlet of the liquid collection part communicates with the liquid discharge pipe, and the liquid discharge pipe includes a main liquid discharge pipe and a secondary liquid discharge pipe. Wherein, a pulley is arranged on the bottom plate, and a slide rail matched...

Embodiment 2

[0068] A device for additively manufacturing a rigid heat-insulating tile body was manufactured that was basically the same as in Example 1, except that the distance between the centers of every two adjacent through holes was 8mm.

[0069] The device in this example was used to manufacture the rigid heat-insulating tile body in the same manner as in Example 1, and the density test was carried out on the 7 layers of slurry included in the manufactured rigid heat-insulating tile body. The results are shown in Table 1 .

Embodiment 3

[0071] A device for additively manufacturing a rigid heat-insulating tile body was manufactured that was basically the same as in Example 1, except that the distance between the centers of every two adjacent through holes was 12 mm.

[0072] The device in this example was used to manufacture the rigid heat-insulating tile body in the same manner as in Example 1, and the density test was carried out on the 7 layers of slurry included in the manufactured rigid heat-insulating tile body. The results are shown in Table 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com