Highly-integrated electric driving wheel

A technology of integrating electricity and driving wheels, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of unfavorable precision control and consistency guarantee, reduce the overall installation performance of the product, and reduce the movement performance, and shorten the assembly process route. , Improve the assembly speed and production efficiency, the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

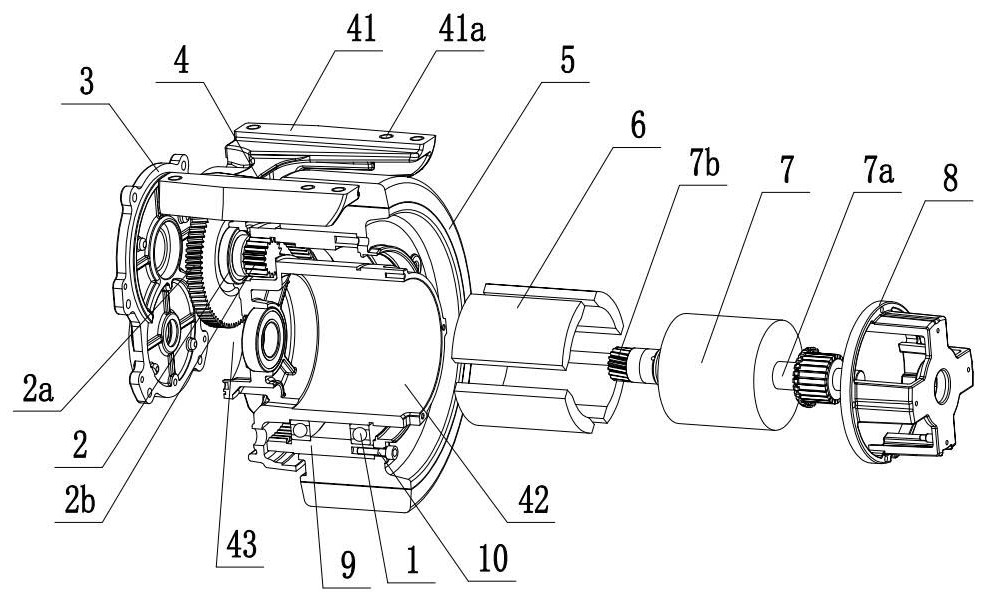

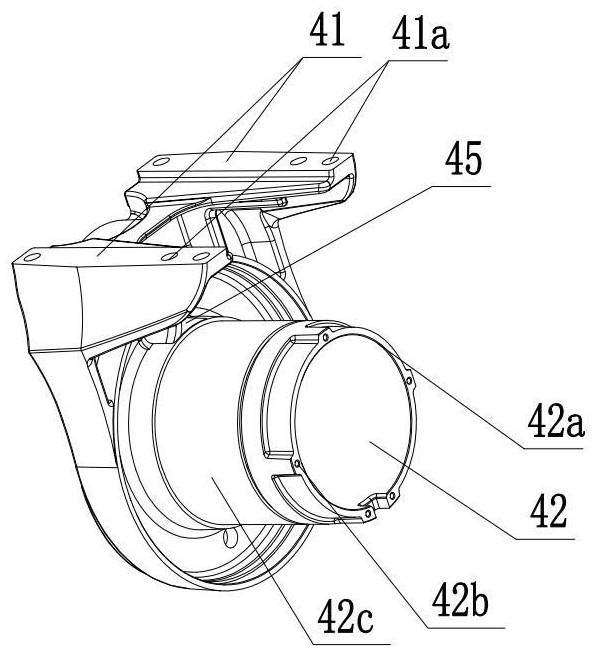

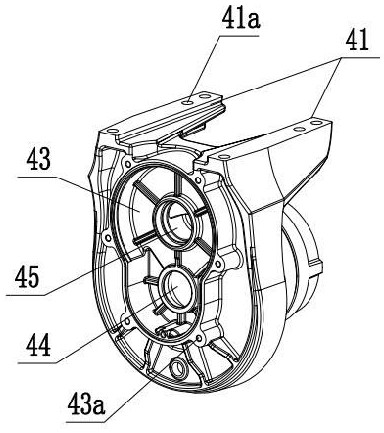

[0021] As shown in the figure, it is a highly integrated electric drive wheel, the gear body 2 and the case cover 3 that cooperate with each other, the stator assembly 6, the rotor assembly 7 and the end cover assembly 8, as well as the wheel body 5, the integrated bracket 4, and the integrated bracket 4 A power chamber 42 is arranged on one side, and the stator assembly 6 is installed in the power chamber 42. The rotor assembly 7 cooperates with the stator assembly 6 to form the stator-rotor matching structure of the motor. A group of end cover installation holes 42b are arranged on the end surface of the power chamber 42. 8 is fastened on the end surface of the power chamber 42 through the end cover mounting hole 42b; the other side of the integrated bracket 4 is provided with a deceleration chamber 43, and part or all of the gear body 2 is installed in the deceleration chamber 43, and a deceleration chamber 43 is provided on the end surface Set the case cover mounting hole 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com