Ball screw support device

A support device and ball screw technology, applied in feeding devices, metal processing mechanical parts, metal processing equipment, etc., can solve the problems affecting the dynamic running stability of the whole machine, the movement accuracy error of the feed axis, affecting the stability of the worktable, etc. problem, to achieve the effect of simple and reliable structure, reduced deflection and deformation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

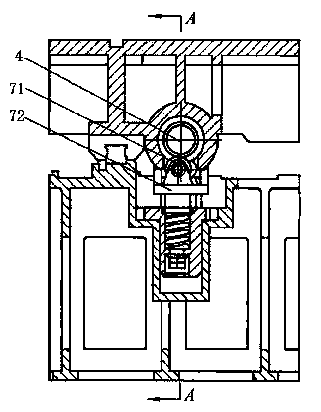

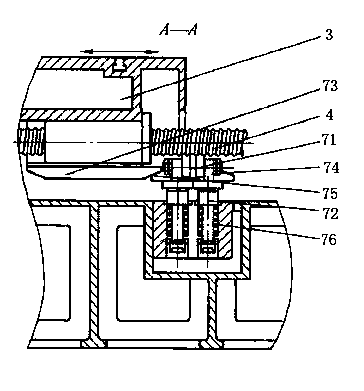

[0012] A ball screw support device proposed by the present invention will be described in detail below with reference to the accompanying drawings.

[0013] Such as figure 1 with 2 As shown, a ball screw supporting device disclosed in the present invention includes a support rod 72, a spring 76, a roller 71, an upper inclined plate 73 and a lower inclined plate 75; the spring 76 is sleeved on the support rod 72, and the support rod 72 has Boss, spring 76 is located below the boss. The upper sloping plate 73 is installed on the external workbench 3 , and the lower sloping plate 75 is installed on the support rod 72 . The roller 71 is installed on the top of the support rod 72 , and the shaft of the roller 71 is fixedly connected with the top of the support rod 72 by a screw 74 . There are two supporting rods 72, springs 76, and rollers 71, which are arranged symmetrically.

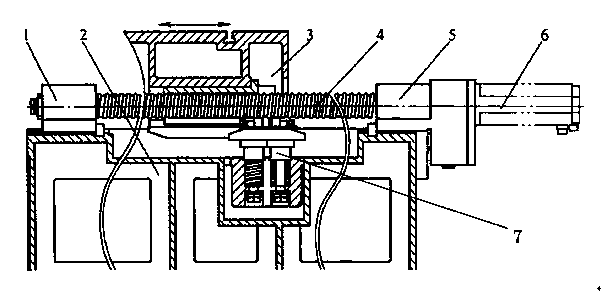

[0014] Such as image 3 As shown, install the ball screw support device 7 on the machine tool. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com