Dual-belt synchronous clamping conveying device

A clamping conveying and conveyor belt technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of unusable contact materials, unsuitable for highly floating materials, and reduced conveying volume, so as to achieve easy automation and centralization Control, realize automation and centralized control, flexible and reliable automatic tensioning mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

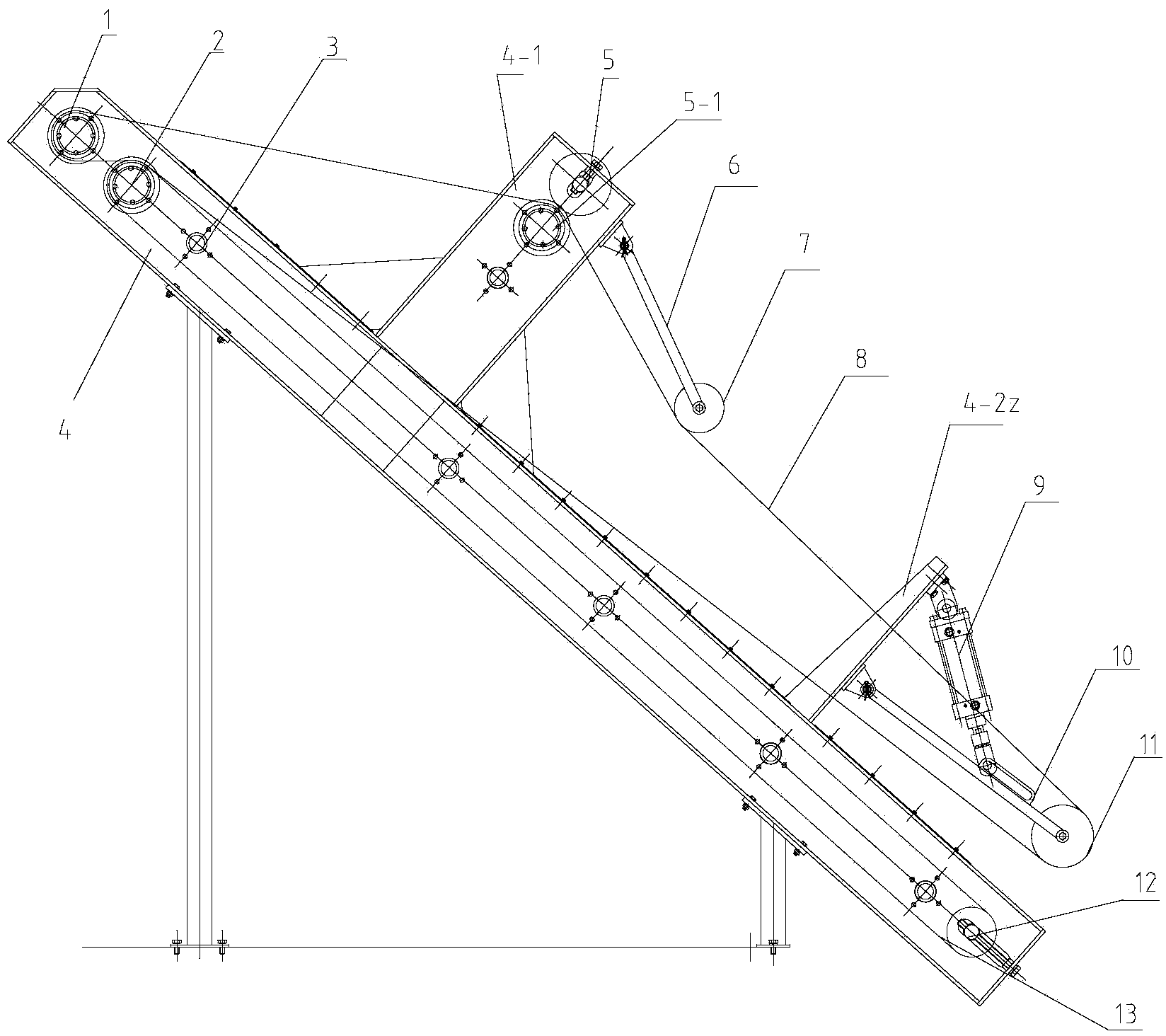

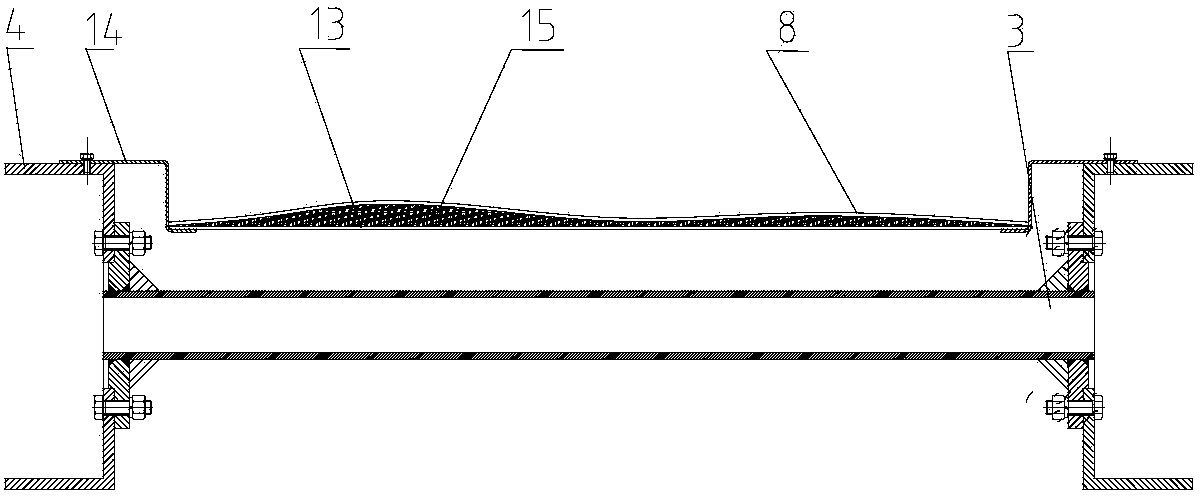

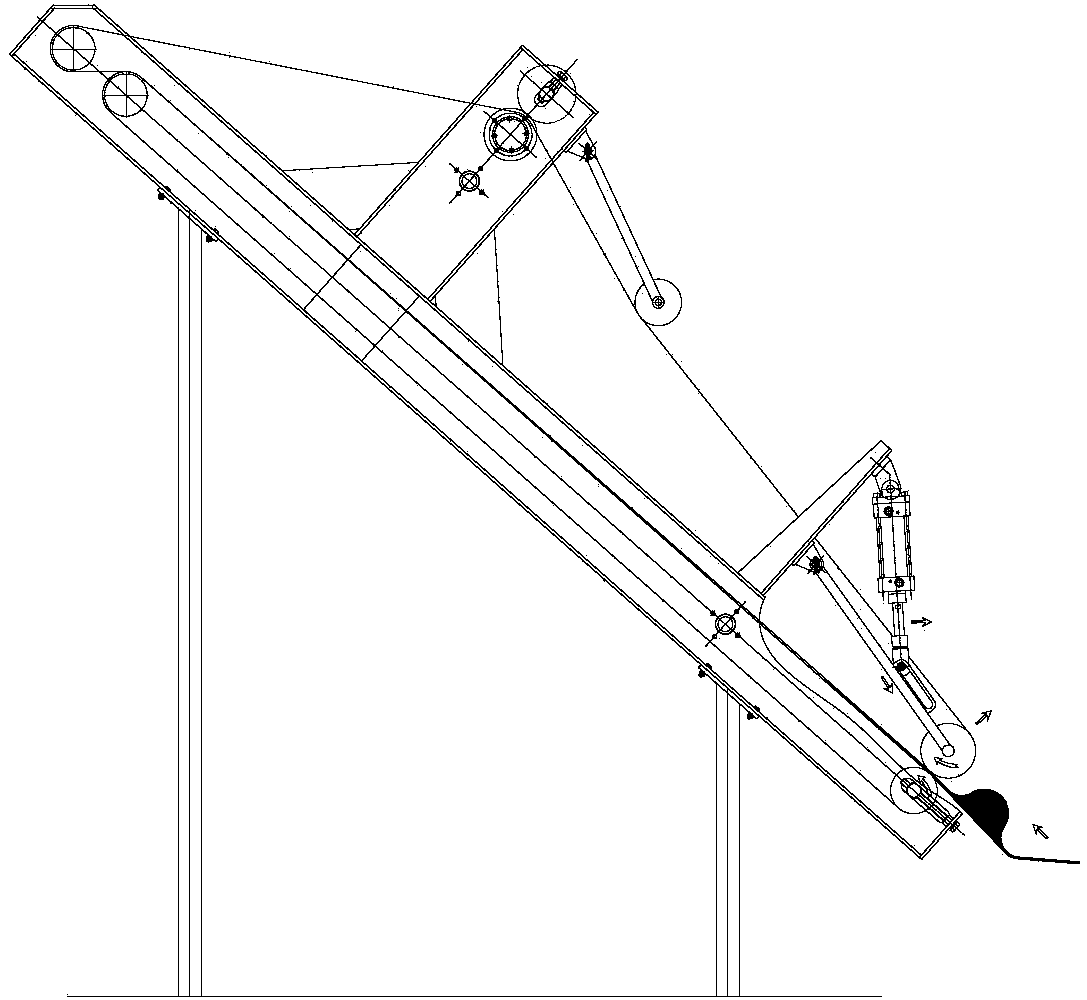

[0018] The dual-belt synchronous clamping and conveying device of this embodiment is as figure 1 and figure 2 As shown, the inclined frame 4 is composed of two channel steel side plates supported on the legs and connected by connecting rods 3 at intervals, and the inner sides of the two side plates are respectively fixed with a Z-shaped section plate whose lower edge is hooked on the edge of the lower conveyor belt 13 14. The upper end and the lower end of the frame 4 support the drive roller 2 and the pull-down tension roller 12 respectively. The driving roller 2 and the pull-down tension roller 12 are surrounded by a lower conveyor belt 13 . An upper frame 4-1 and a lower frame 4-2 perpendicular thereto extend from the upper part and the lower part of the frame 4 respectively. A driven roller 1 is also supported on the driving roller 2 of the frame 4, a synchronous driving roller 5-1 is supported on the upper frame 4-1, and a swing bar 6 with a floating roller 7 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com