A light steel beam and its structural steel skeleton

A light steel and structural steel technology, applied in truss structures, joists, girders, etc., can solve the problems of increasing the overall weight of steel load-bearing plates, deflection deformation, and inability to meet high-strength requirements, and achieve the goal of improving applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The core of the present invention is to provide a structural steel skeleton of a light-weight steel beam. Through the optimized design of the structure, the overall weight can be effectively reduced, the deflection deformation can be reduced, and the strength in all directions can be improved. On this basis, the present invention also provides a light-weight steel beam with the structural steel frame.

[0040] In order to make those skilled in the art better understand the solution of the present invention, the present embodiment is described in detail below with reference to the accompanying drawings.

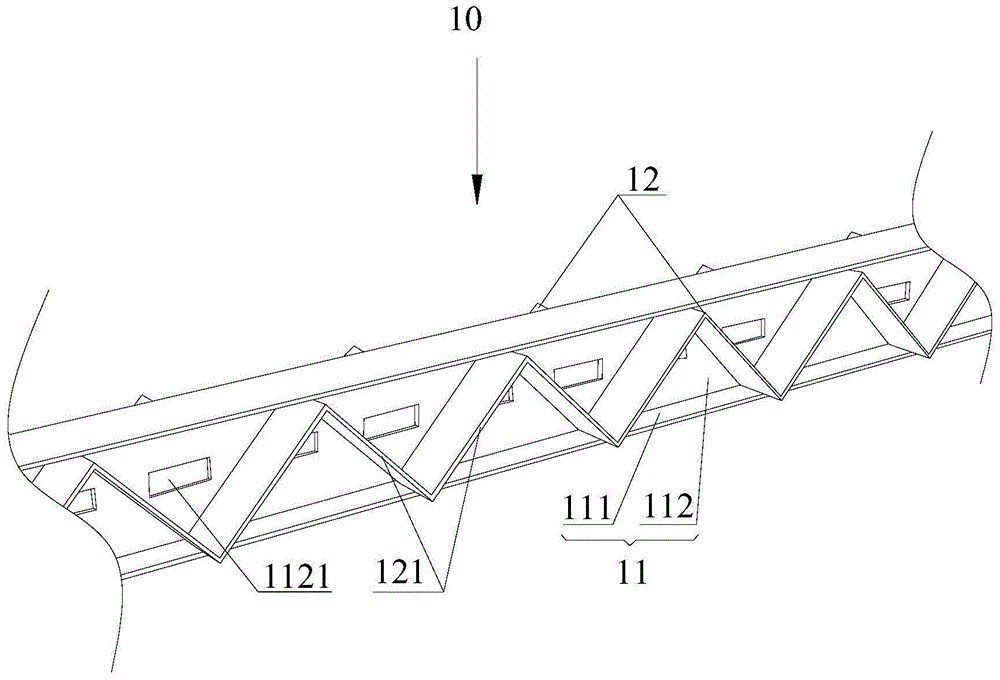

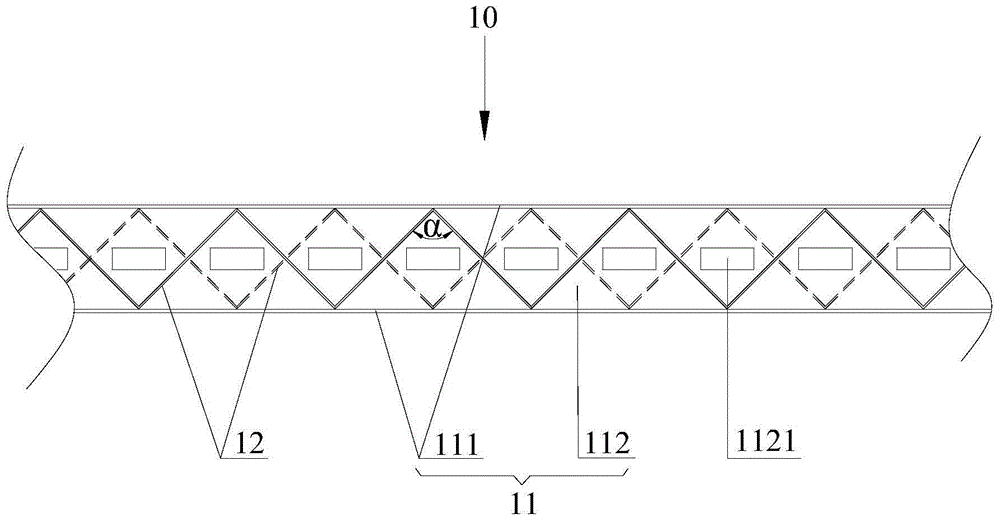

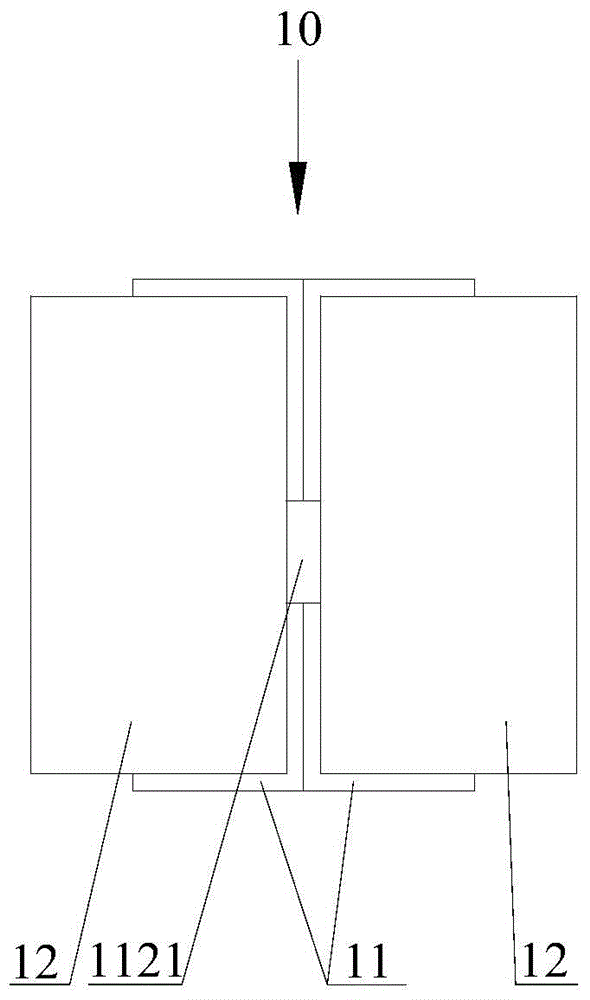

[0041] See Figure 1 to Figure 5 shown, where, figure 1 is a schematic structural diagram of a structural steel frame in a specific embodiment; figure 2 for figure 1 A side schematic diagram of ; image 3 for figure 2 the left view of ; Figure 4 is the structural schematic diagram of the frame body in the specific embodiment; Figure 5 It is a schematic diagra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com