Hydraulic concrete structure composite prestress reinforcing system and construction method thereof

A hydraulic concrete and prestressing technology, applied in building construction, building maintenance, construction, etc., can solve the problems of not being able to improve the lateral stiffness of the structure or closing the lateral cracks, not being able to be arranged on the side of the structure, and difficult to prevent corrosion and protection. , to achieve the effect of convenient anchoring and tensioning, increased strength and rigidity, and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

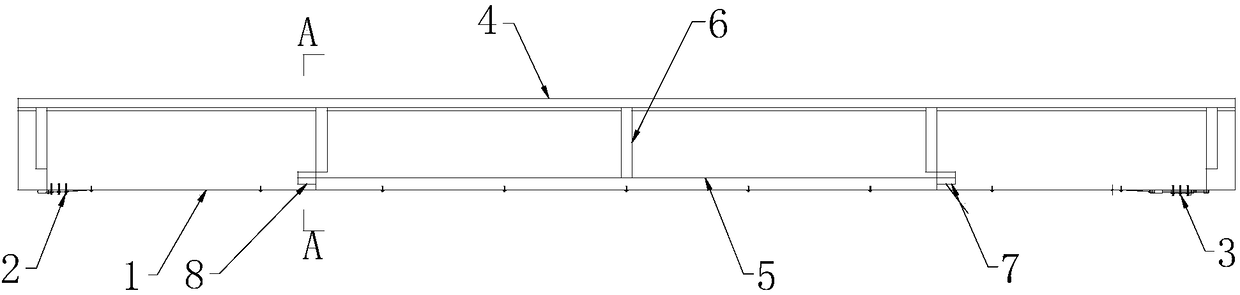

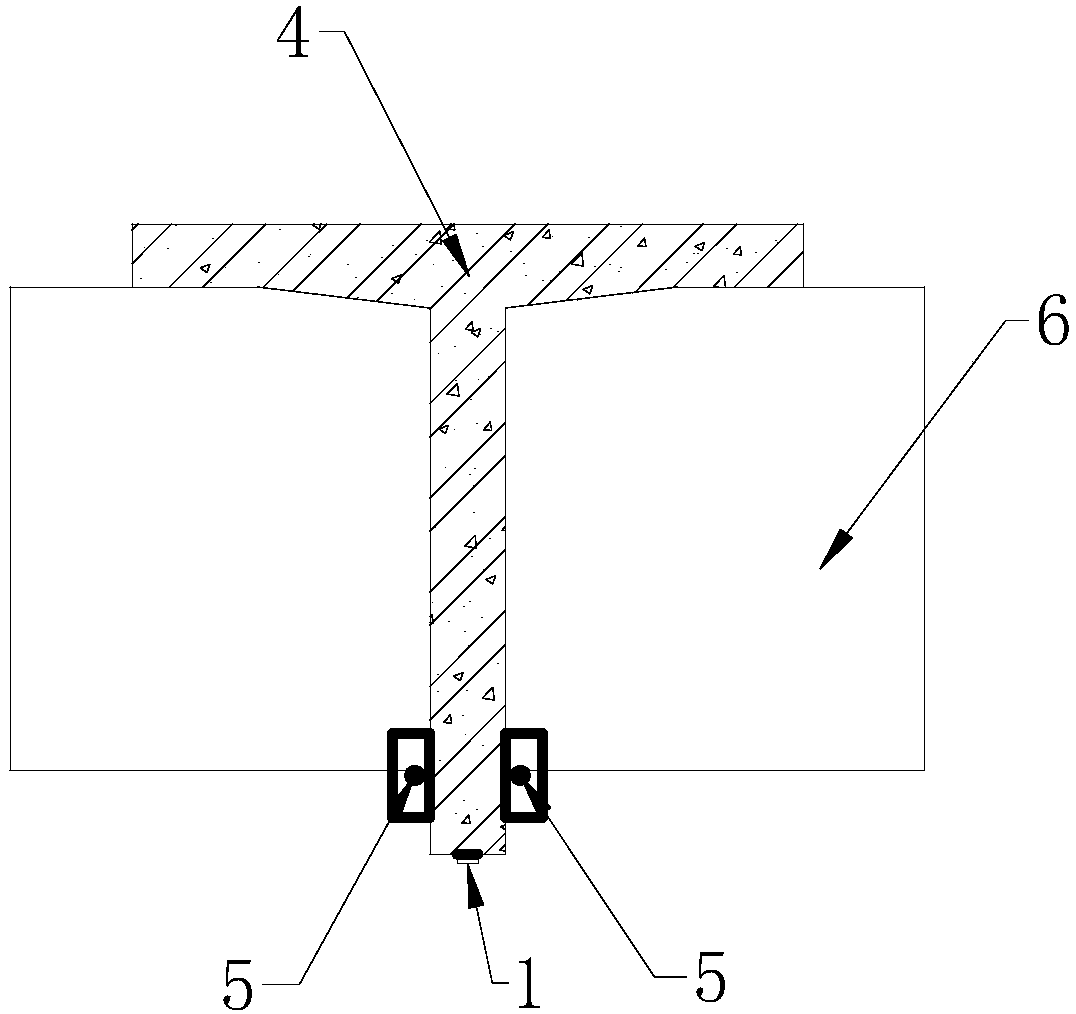

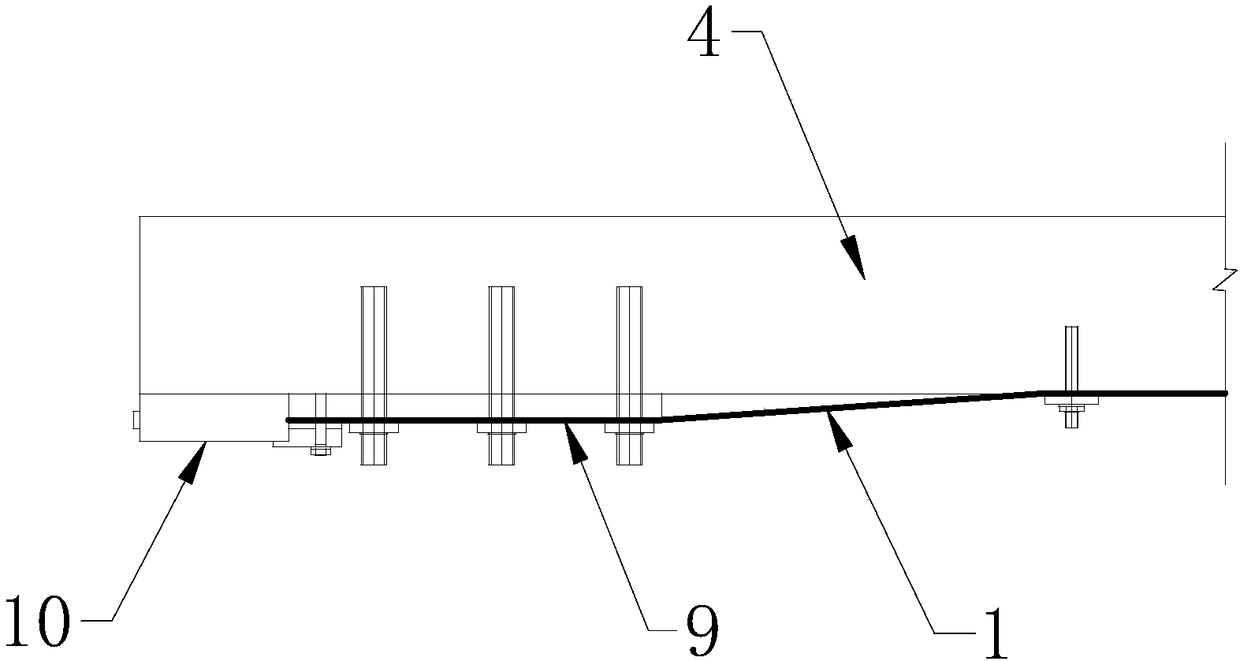

[0059] see Figure 1-10 shown;

[0060] A composite prestressed reinforcement system for hydraulic concrete structures of the present invention comprises:

[0061] The prestressed carbon fiber plate 1, the two ends of the prestressed carbon fiber plate 1 are respectively fixed on the bottom end of the hydraulic concrete T-beam 4 through the first anchor mechanism 2 and the first tension mechanism 3; it also includes,

[0062] At least two prestressed steel strands 5, the prestressed steel strands 5 are symmetrically fixed under the partition plate 6 on both sides of the bottom of the hydraulic concrete T-beam 4, one end of the prestressed steel strand 5 is connected to the second tension The mechanism 6 is connected, the second tensioning mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com