Fabrication and assembly process of integrally prestressed total-assembled box type modular trestle

An assembly process and prestressing technology, applied in the erection/assembly of bridges, portable bridges, bridges, etc., can solve the problems such as the inability of the enclosure structure and the stressed structure to work as a whole, the large amount of work on the construction site, and the large deflection and deformation of the work. , to achieve the effect of reasonable force, obvious steel consumption and less safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

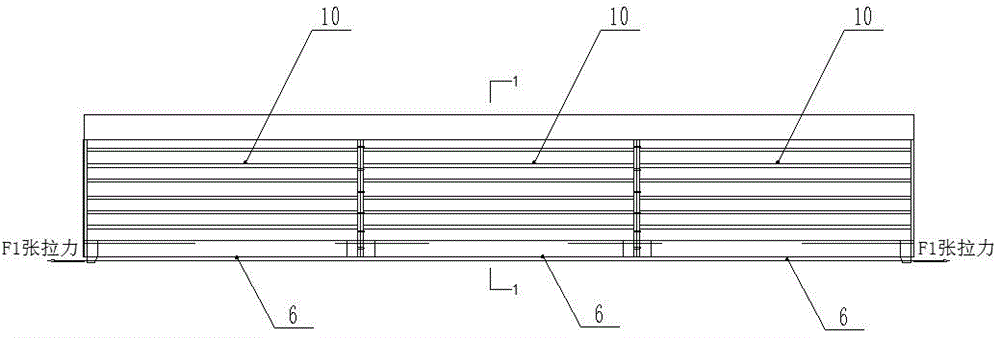

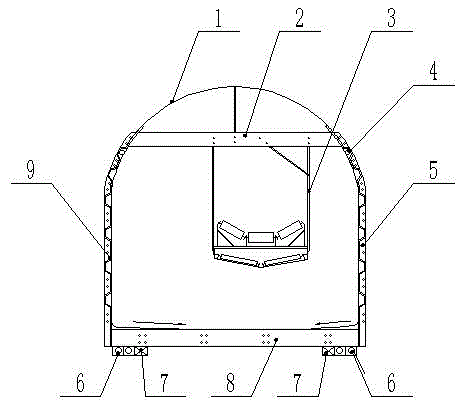

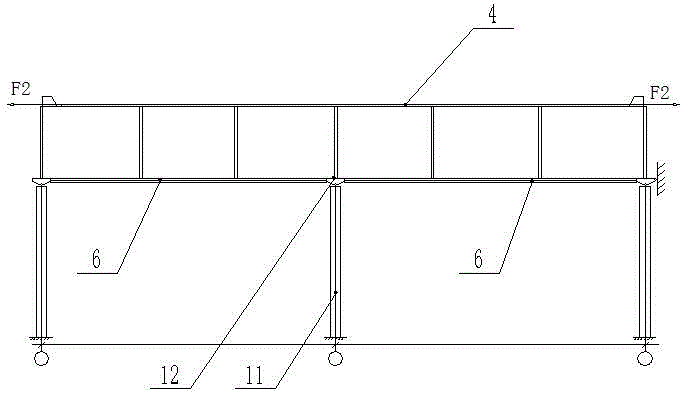

[0035] Such as Figure 1-Figure 3 As shown, the manufacturing and assembly process of the overall prestressed fully assembled box-type modular steel trestle is carried out in accordance with the following steps:

[0036] The first step is to ensure that the lifting and assembly site is flat and compacted, and the ground bearing capacity and flatness meet the assembly requirements;

[0037] The second step is to accurately measure the position of the skid 7, find out the elevation of the top surface of the skid 7, and arch according to the design in the single span;

[0038] In the third step, at least two box-shaped modules 10 are hoisted sequentially on the skids 7 in sections, and the interfaces of the box-shaped modules 10 are aligned, and the vertical length of the box-shaped modules 10 is straightened;

[0039] The fourth step is to sequentially fasten two adjacent box-shaped modules 10 with bolts, and the tightening torque should reach the design value;

[0040] The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com