Compression roller of composite machine for preparing polyethylene fiber reinforced composite material

A reinforced composite material and polyethylene fiber technology, which is applied in the field of compound machines, can solve the problems affecting the process stability, uneven performance, and roll wall deflection and deformation of polyethylene fiber laminated cloth, so as to achieve stable lamination process and uniform performance , Reduce the effect of deflection deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention provides a press roll on a composite machine for preparing polyethylene fiber reinforced composite materials. The specific implementation of the press roll used for preparing polyethylene fiber reinforced composite materials provided by the present invention will be described below with examples.

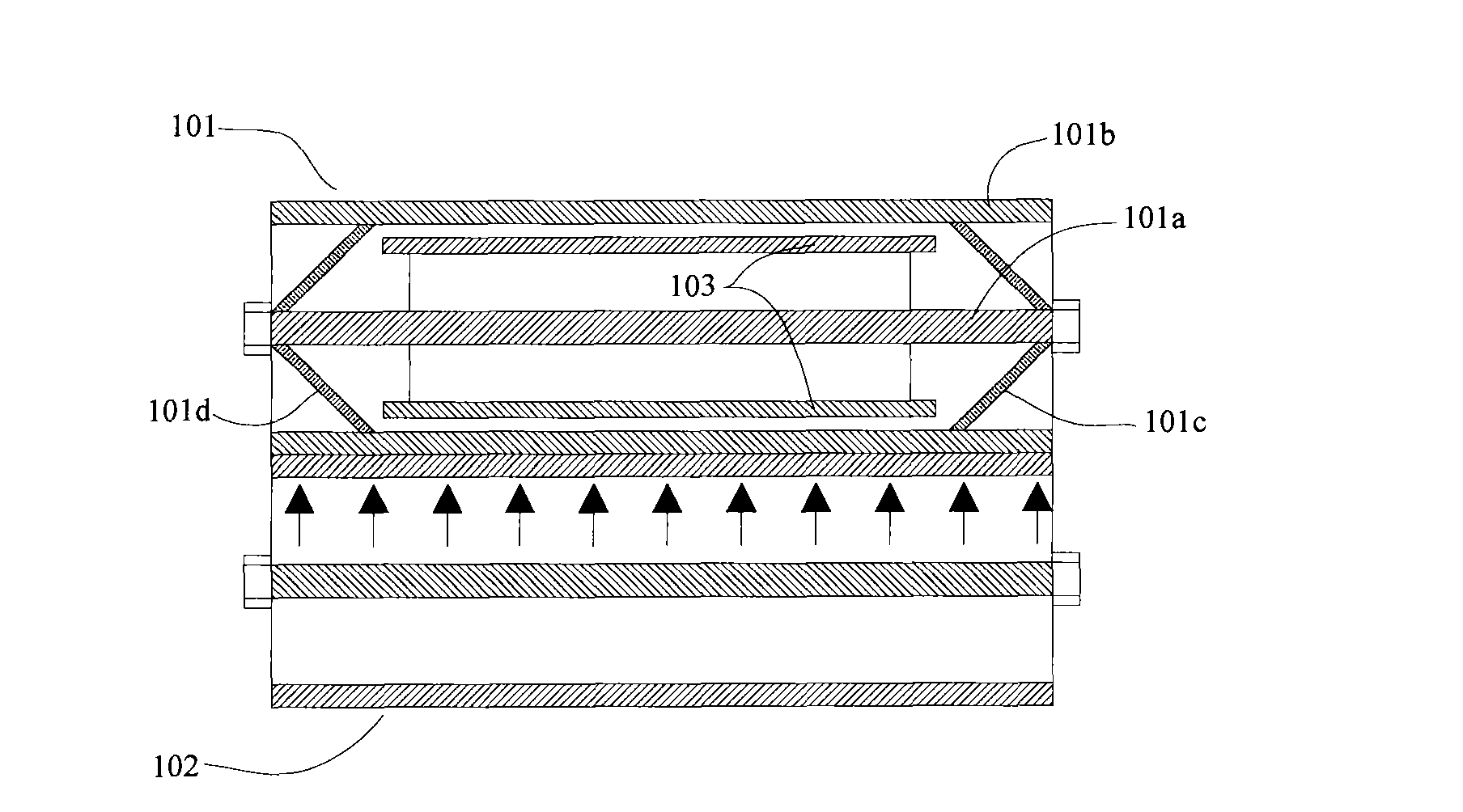

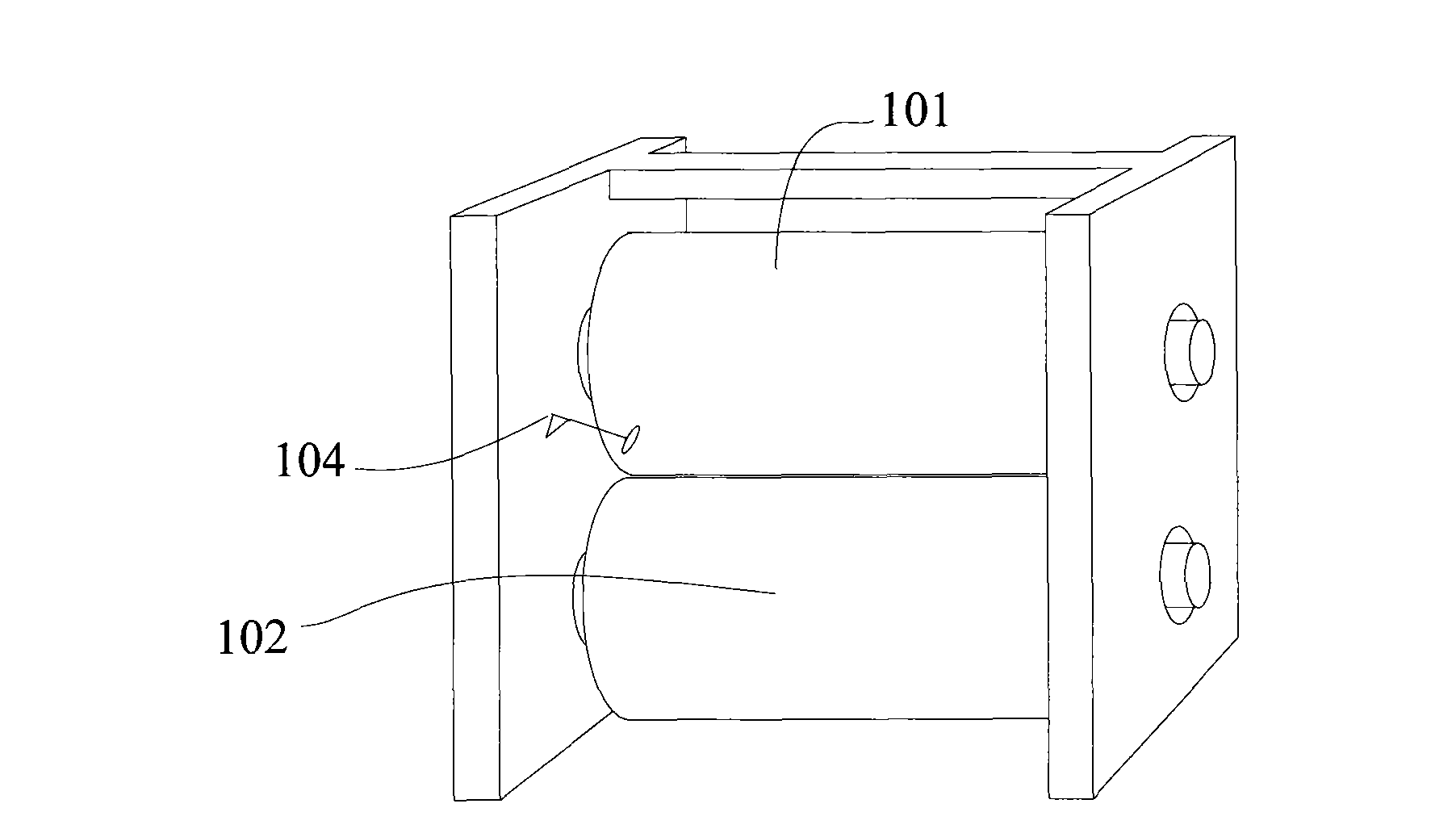

[0026] see figure 1 and figure 2 , figure 1 The schematic diagram of the press roller on the composite machine for preparing polyethylene fiber reinforced composite material provided by the first embodiment of the present invention, figure 2 A schematic diagram of a compound machine composed of a pressure roller and a back-up roller provided in this embodiment. The pressure roller 101 provided in this embodiment includes a shaft 101a with a length of 1800mm and a diameter of 80mm, and a hollow roller 101b with a diameter of 400mm, a wall thickness of 25mm and a length of 1400mm is sheathed outside the shaft 101a. The hollow roller 101b is horizontal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com