Hydraulic gear pump

A technology of hydraulic gear pumps and driving gears, which is applied in the field of hydraulic gear pumps, can solve the problems that the service life cannot be extended, the rated pressure of the gear pump cannot be improved, and the bearing capacity of the driven gear cannot be enhanced, so as to achieve high working pressure , reduce scraping phenomenon, good effect

Inactive Publication Date: 2005-03-23

徐福刚

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing technology adopts a completely symmetrical structural design of the driving and driven gears, which cannot enhance the bearing capacity of the driven gear, the rated pressure of the gear pump cannot be increased, and the service life cannot be extended

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0015] D1(mm)

Embodiment 2

[0017] D1(mm)

Embodiment 3

[0019] D1(mm)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

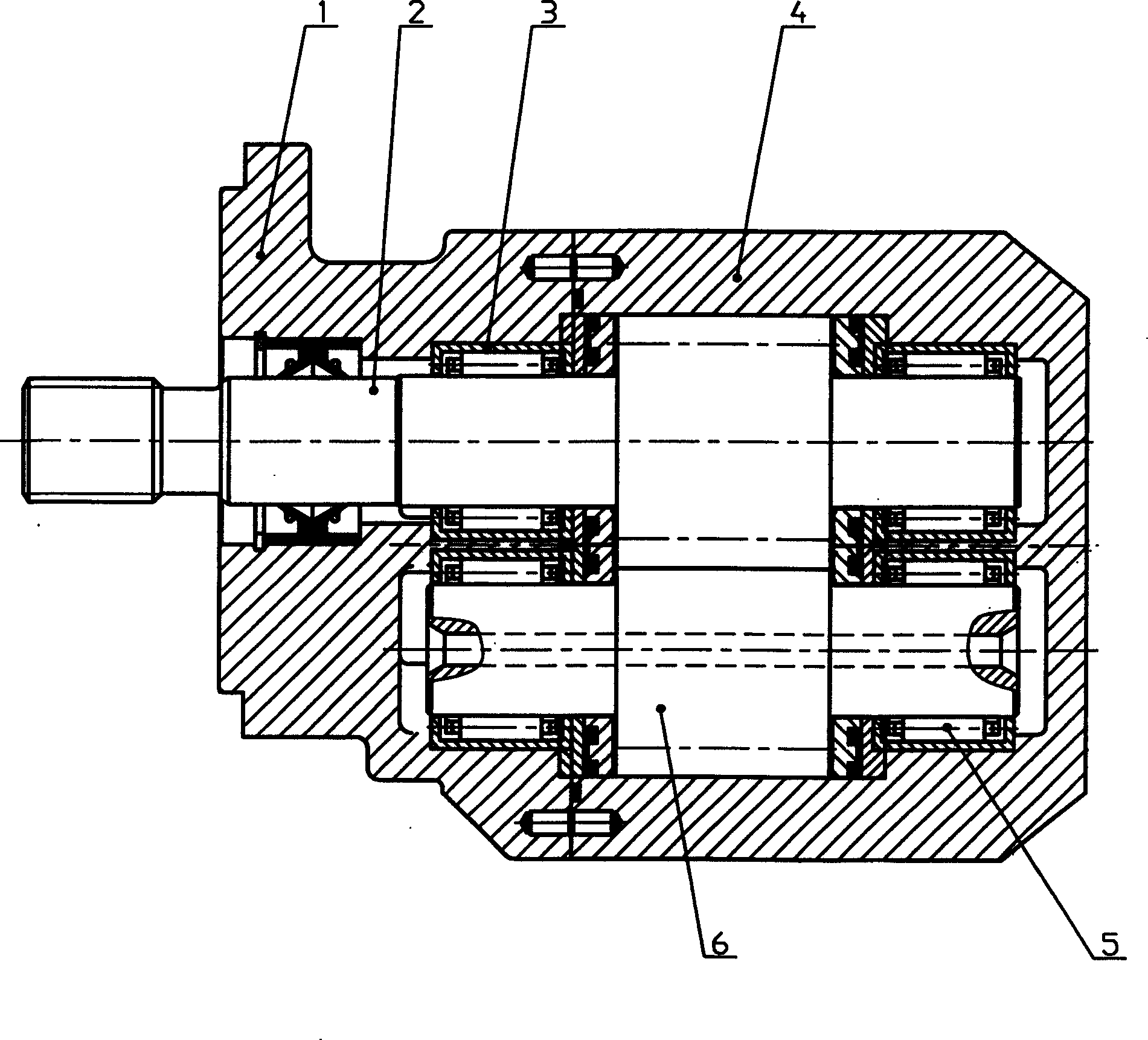

The invention relates to a hydraulic pressure gear pump. It is used to improve the working press and length of life of the hydraulic pressure but need not to change the structure of the original pump body. It includes drive gear which is fasten by two drive gear axle bearing and driven gear which is fasten by two driven gear axle bearing, the particular lie on the external diameter of the driven gear must be greater than the drive gear's. The advantages are simple processing, high operation pressure and long service life.

Description

(1) Technical field [0001] The invention relates to a hydraulic gear pump, in particular to a hydraulic gear pump with different bearing structures. (2) Background technology [0002] The resultant force of the hydraulic radial force and meshing force on the main and driven gears inside the hydraulic gear pump is not equal. , The bearing of the driven gear wears faster and is damaged first. To be precise: the life of the gear pump is determined by the life of the bearings at both ends of the driven gear. The existing technology adopts a completely symmetrical structural design of the driving and driven gears, which cannot enhance the bearing capacity of the driven gears, the rated pressure of the gear pump cannot be improved, and the service life cannot be extended. (3) Contents of the invention [0003] In order to overcome the deficiencies of the above technologies, the present invention provides a gear pump with a different structural scheme for the supporting bearing...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04C2/14

Inventor 徐福刚于桂忠

Owner 徐福刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com