Device and method for reversely pulling and shelling lengthening type torpedo anchor

A technology of pull-back shelling and torpedo anchors, applied in anchor points, transportation and packaging, ship construction, etc., can solve the problems of inability to improve the bearing capacity of torpedo anchors in an all-round way, the overall stability of the unfolded structure, quantity and size constraints and other problems, to avoid the failure of the unfolded structure, save production costs, transportation and installation costs, and reduce its own weight and size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

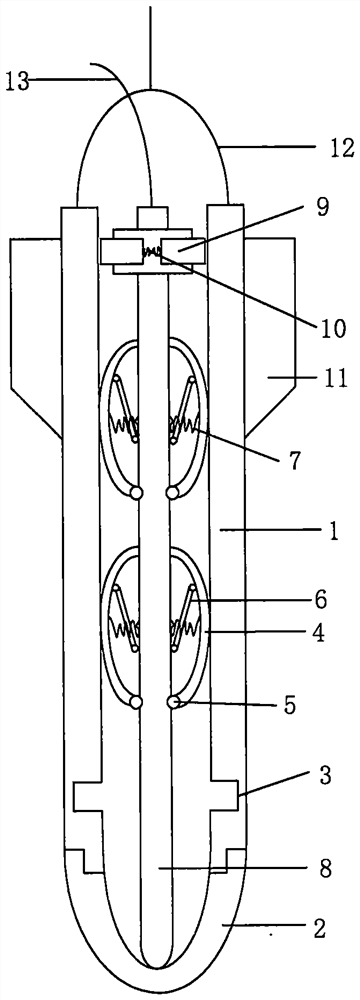

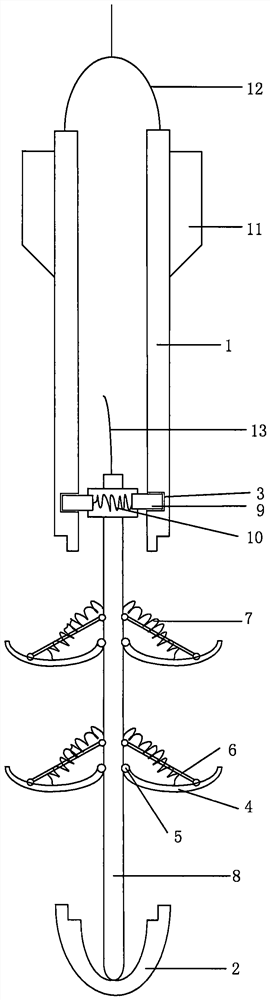

[0029] Such as figure 1 Shown, a kind of device of anti-pull shelling growth type torpedo anchor, comprises anchor body 1, anchor head 2, draw-in groove 3, arc-shaped spreading knife 4, hinge point 5, pull rod 6, high pressure spring 1 7, center bar 8 , chuck 9, high pressure spring II 10, empennage 11, working anchor chain 12, temporary hanging chain 13;

[0030] The anchor head 2 and the anchor body 1 are overlapped by bayonet staggered seams, and can be separated under the action of tension; the top of the anchor head 2 is fixedly connected to the lower end of the middle bar 8, and the anchor head 2 and the middle bar 8 keep moving synchronously;

[0031] Four empennages 11 are symmetrically arranged around the tail of the anchor body 1; a card slot 3 is provided inside the anchor body 1, allowing the chuck head 9 to be fixed under the action of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com