An industrial robot deceleration device

An industrial robot and deceleration device technology, which is applied in the field of robots, can solve problems such as the influence of the working environment of the device, damage to internal components, and reduced assembly accuracy, so as to avoid errors, reduce noise, and reduce wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

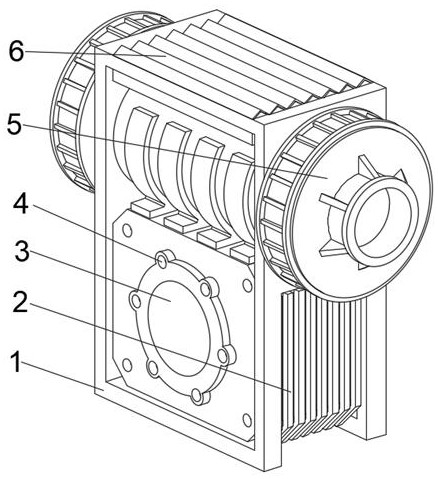

[0041] see Figure 1-6 , the present invention provides a technical solution: an industrial robot deceleration device, including a main body 1, a cover plate 3 is fixedly connected to the middle of the front bottom of the main body 1, and a communication hole 4 is opened on both sides of the front of the cover plate 3, and the main body 1 The bottom of both sides of the outer wall is fixedly connected with the support plate 2, and the middle position of the top of the inner wall on both sides of the main body 1 is provided with a deceleration device 5. Dustproof plate 6;

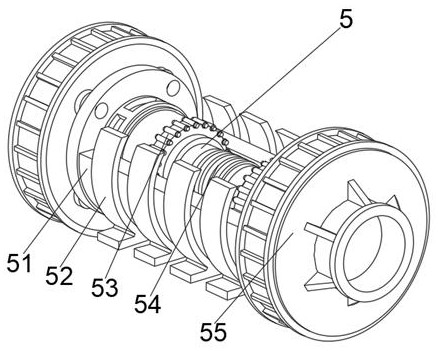

[0042] The speed reduction device 5 includes a synchronous sleeve 54, the two ends of the synchronous sleeve 54 are fixedly connected with a linkage mechanism 53, and the bottom of the linkage mechanism 53 is provided with a connecting housing 51, and both sides of the linkage mechanism 53 penetrate the connecting housing 51 and extend to the connecting housing 51. Outside the housing 51, the bottom of the ...

Embodiment 2

[0048] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using an industrial robot deceleration device, step 1: install the equipment, and fix the dustproof plate 6 with the main body 1, and install the deceleration device 5 is fixedly connected with the main body 1, and connects the main body 1 with the driver;

[0049] Step 2: The internal rotation of the transmission chamber generated by connecting the housing 51 and the synchronous sleeve 54 is carried out, and as the linkage mechanism 53 and the synchronization sleeve 54 rotate together, the fastening mechanism 55 and the linkage mechanism 53 are fixedly connected to make it It plays the role of driving the internal emergency stop fastening, and fixedly connects the connection housing 51 with the balance side plate 52;

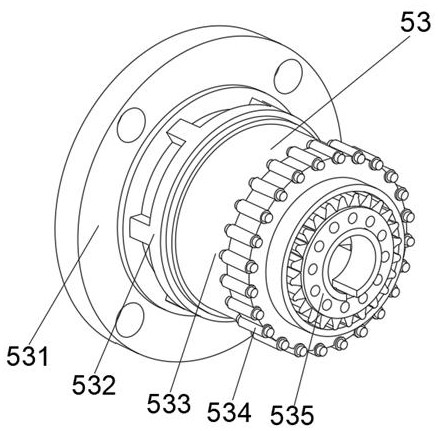

[0050] Step 3: use the reduction gear 535 to precisely control the rotating parts, connect the fixed connection plate 531 with the rigid re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com